Brush tufting machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

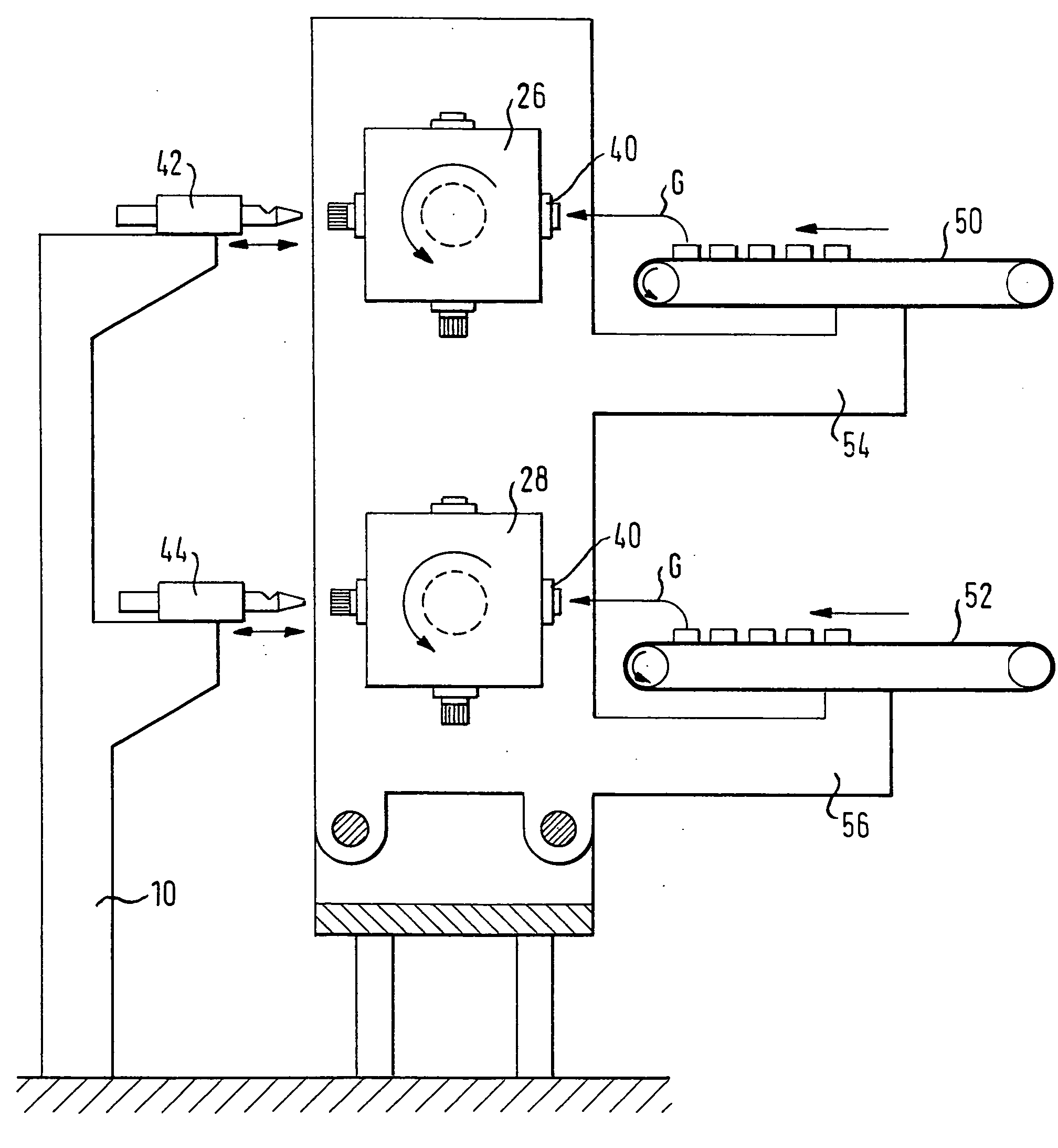

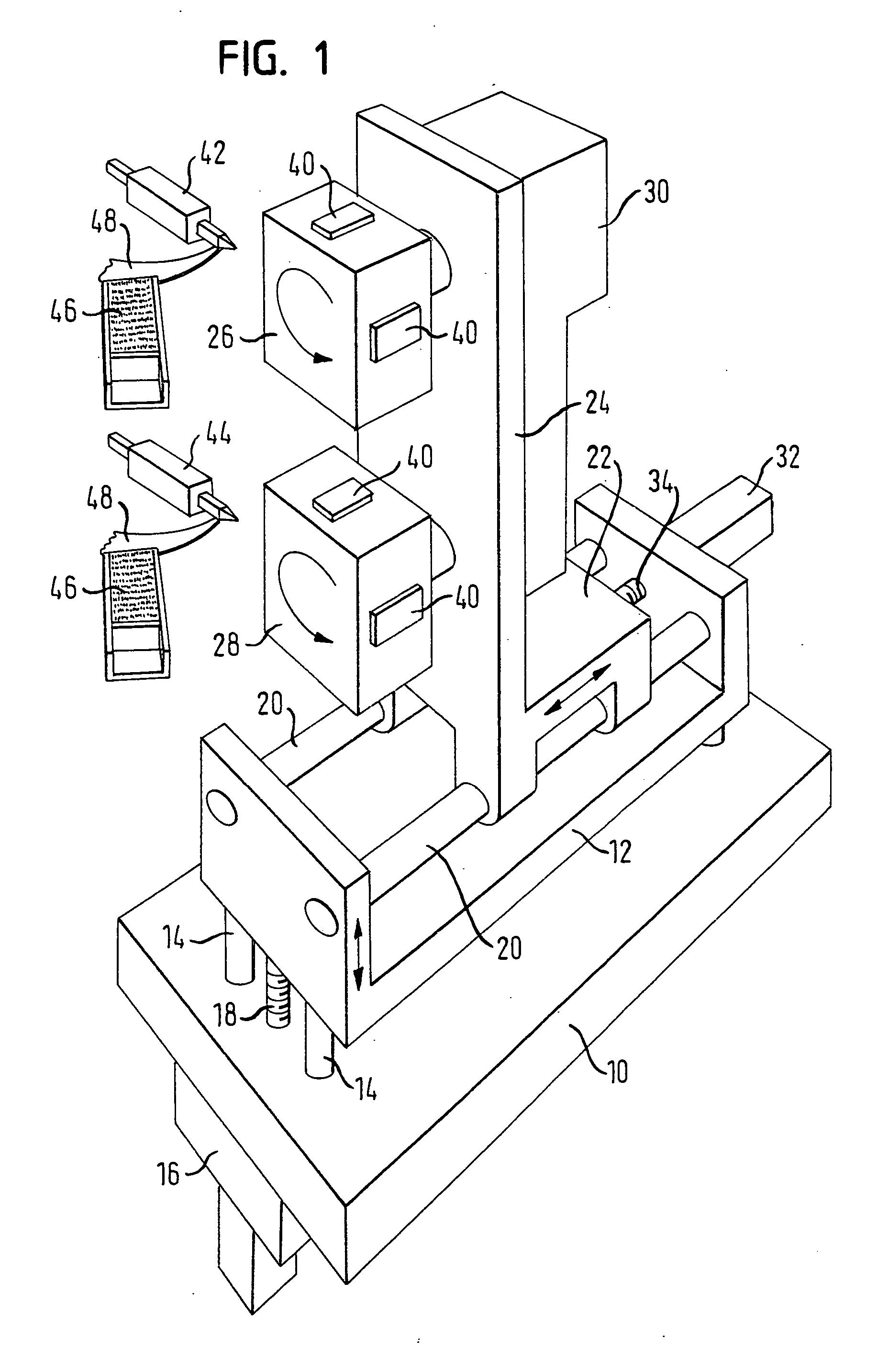

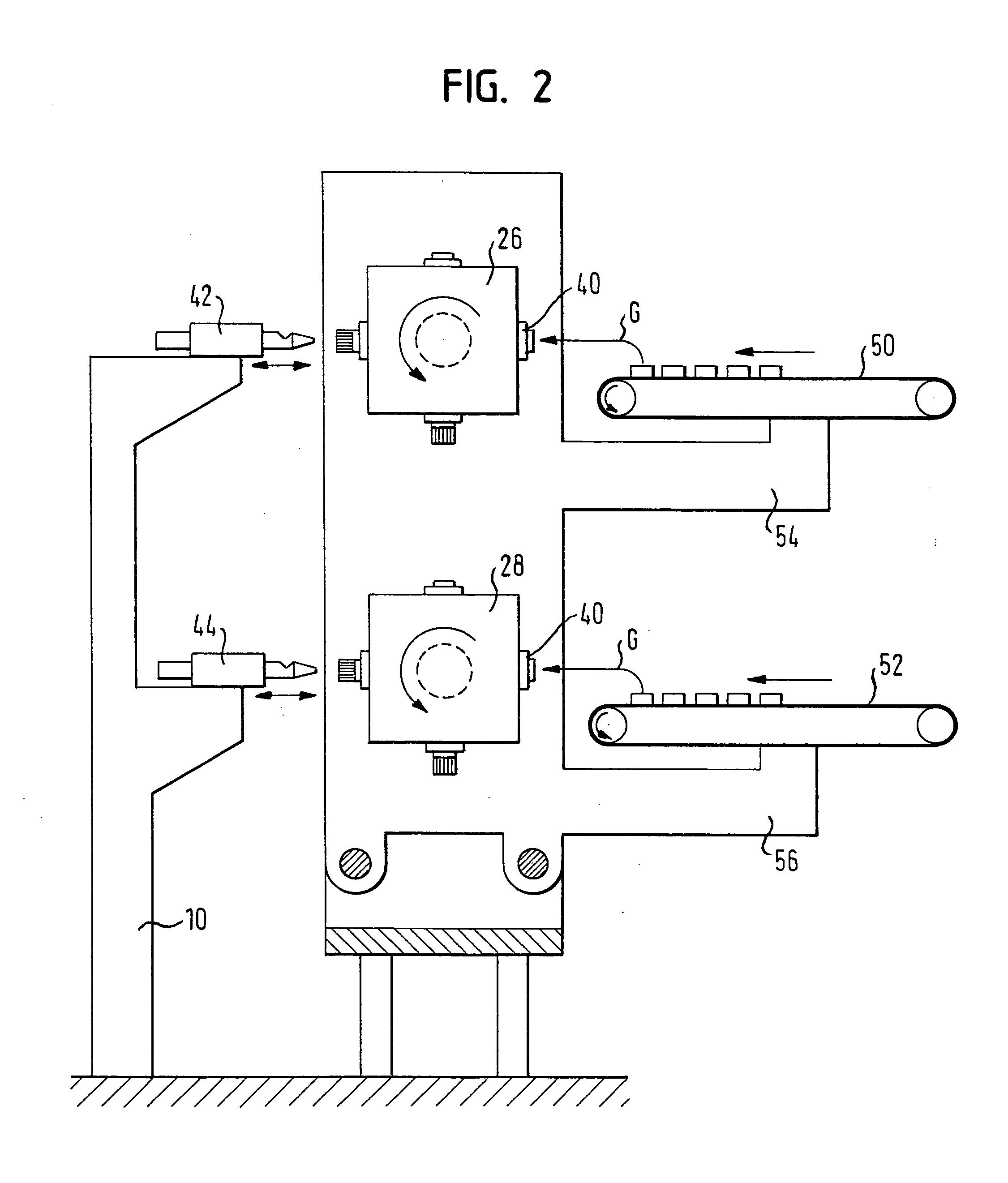

[0011] In the brush tufting machine shown in FIG. 1, a machine tool table 10 is provided, on which a lifting frame 12 is guided on slide bars 14 for vertical reciprocating movement. A drive 16 that is arranged beneath the machine tool table 10 and is coupled to the lifting frame 12 by a spindle 18 drives the lifting frame, as indicated by a vertical double arrow. The lifting frame 12 carries two horizontal slide bars 20 on which a slide 22 is guided for reciprocating movement. The slide 22 is rigidly connected to a vertical supporting plate 24 having two drums 26, 28 mounted thereon for rotation on one horizontal shaft each, the drums 26, 28 being arranged vertically one on top of the other and at a distance from each other. The drums 26, 28 are indexable in steps of 90°. They are driven synchronously by a shared indexing drive 30. As an alternative, each drum 26, 28 may have a drive of its own. The slide 22 is driven to perform a horizontal reciprocating movement by a drive 32 arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com