Roll-type sandpaper with cutting lines and apparatus for manufacturing cutting lines

a technology of rolling-type sandpaper and cutting lines, which is applied in the field of rolling-type sandpaper with cutting lines and manufacturing cutting lines, can solve the problems of requiring a large storage volume, affecting the work efficiency of workers, and inconvenient cutting of conventional sandpaper by using an additional cutting tool, so as to improve work efficiency, reduce labor intensity, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

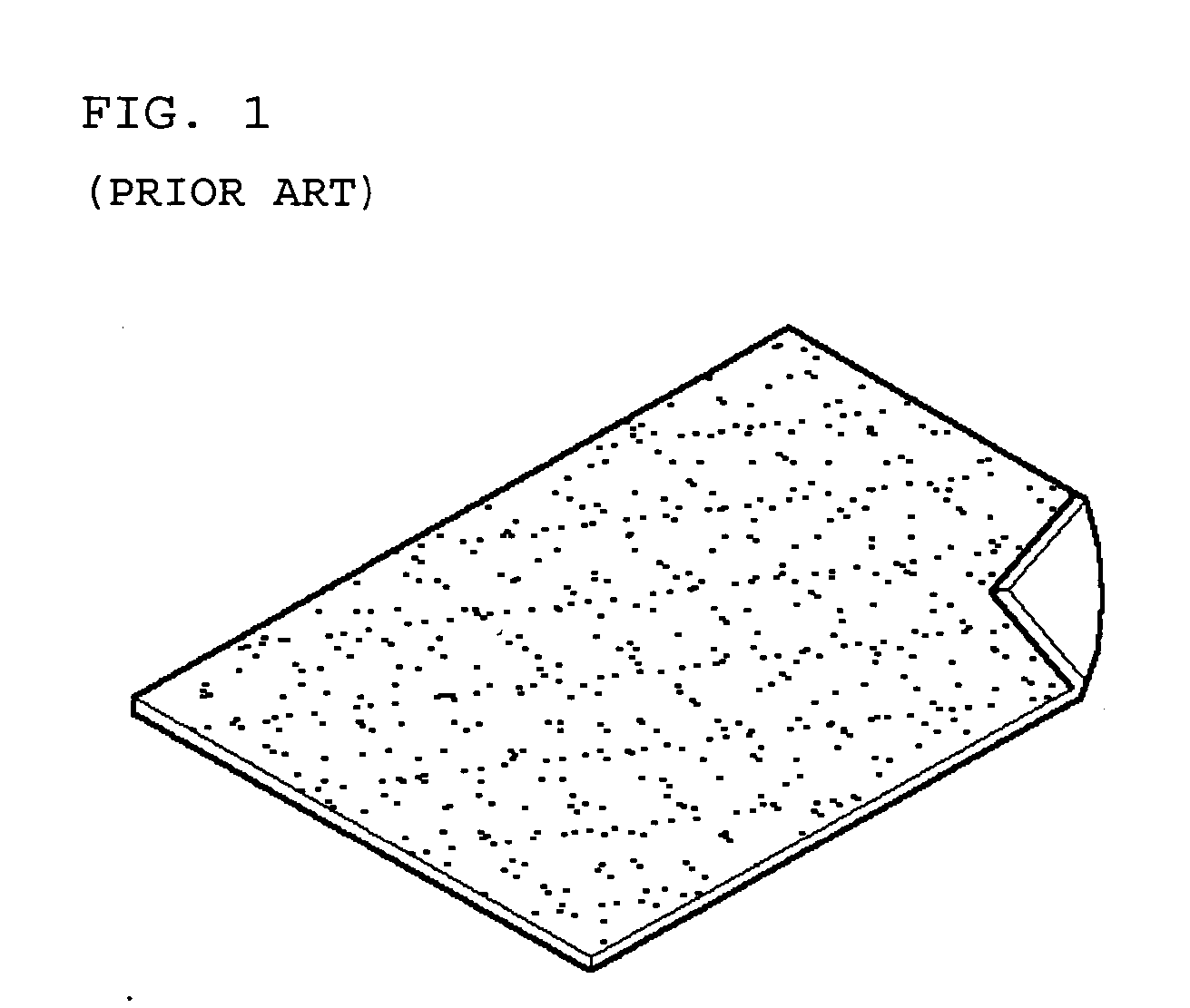

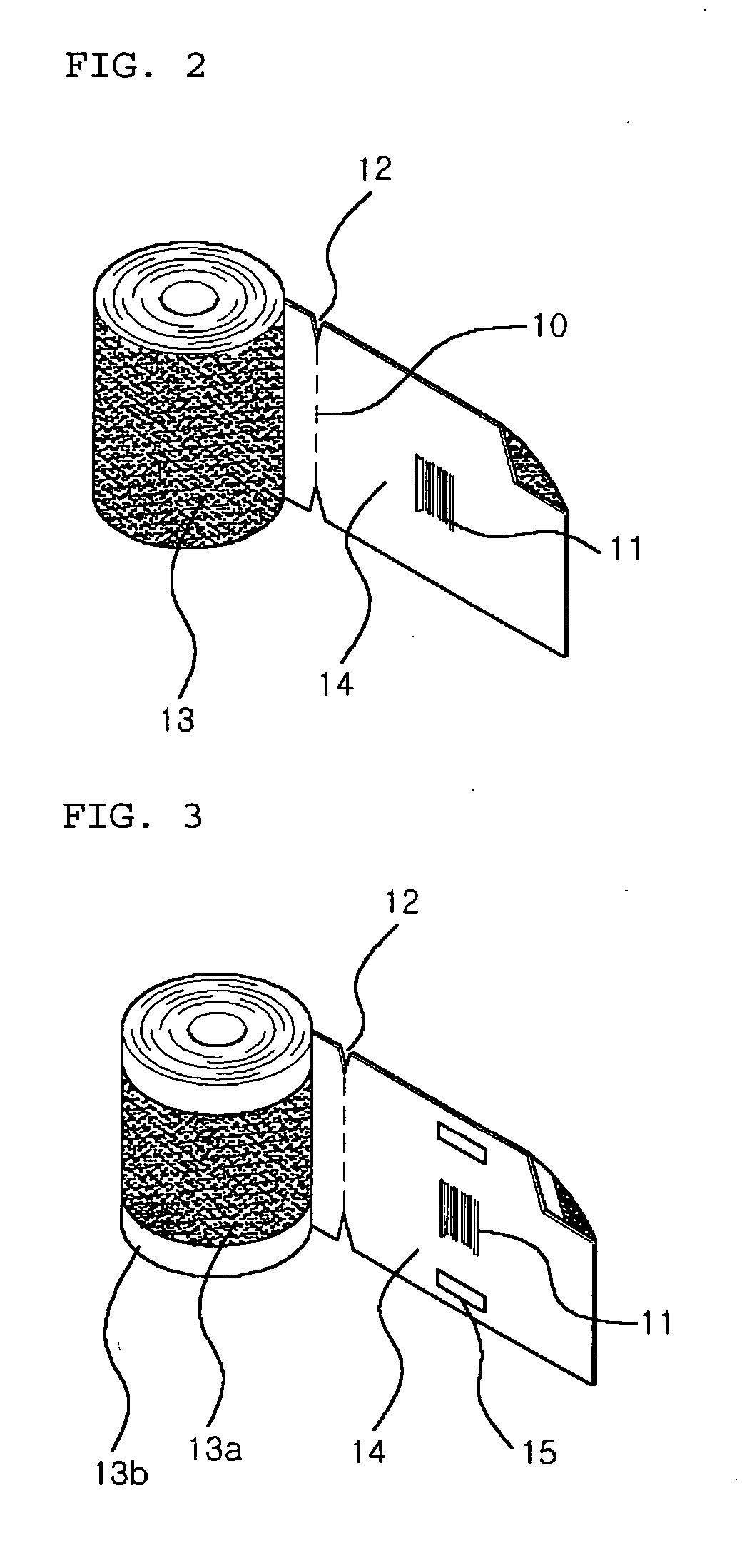

[0020]FIG. 2 is a perspective view of a roll-type sandpaper, which has cutting lines 10, barcodes 11 and V-shaped cuts 12, according to the present invention.

[0021] As shown in FIG. 2, the sandpaper that is rolled comprises a base sheet made of paper or fabric, in which an abrasive is coated on a front surface 13 of the base sheet, and a plurality of cutting lines are formed in parallel by predetermined intervals on a back surface 14 of the base sheet. Further, the cutting line 10 of the sandpaper has a plurality of slits, and thus, is in the temporarily cut state. Hence, the sandpaper can be easily cut along the respective cutting lines 10 even without an additional cutting tool. In such a case, the intervals between the cutting lines 10 may vary, for example, 10, 40, 50 cm and 1 m, depending on end uses or shapes of the sandpaper. Alternatively, instead of the cutting lines 10 each having the plurality of the slits, a plurality of grooves, serving as a temporary cutting line, may ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com