Configurable connectorized I/O system

a connectorized i/o system and configuration technology, applied in the direction of electrical programme control, programme control, coupling device connection, etc., can solve the problems of inconvenient arrangement of the cable from the input or output module to the plc, the inability to generally connect directly to the sensor or actuator, and the inability to facilitate the connection of the cable. , to achieve the effect of reducing the time required, eliminating or minimizing the need for custom cable harnesses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

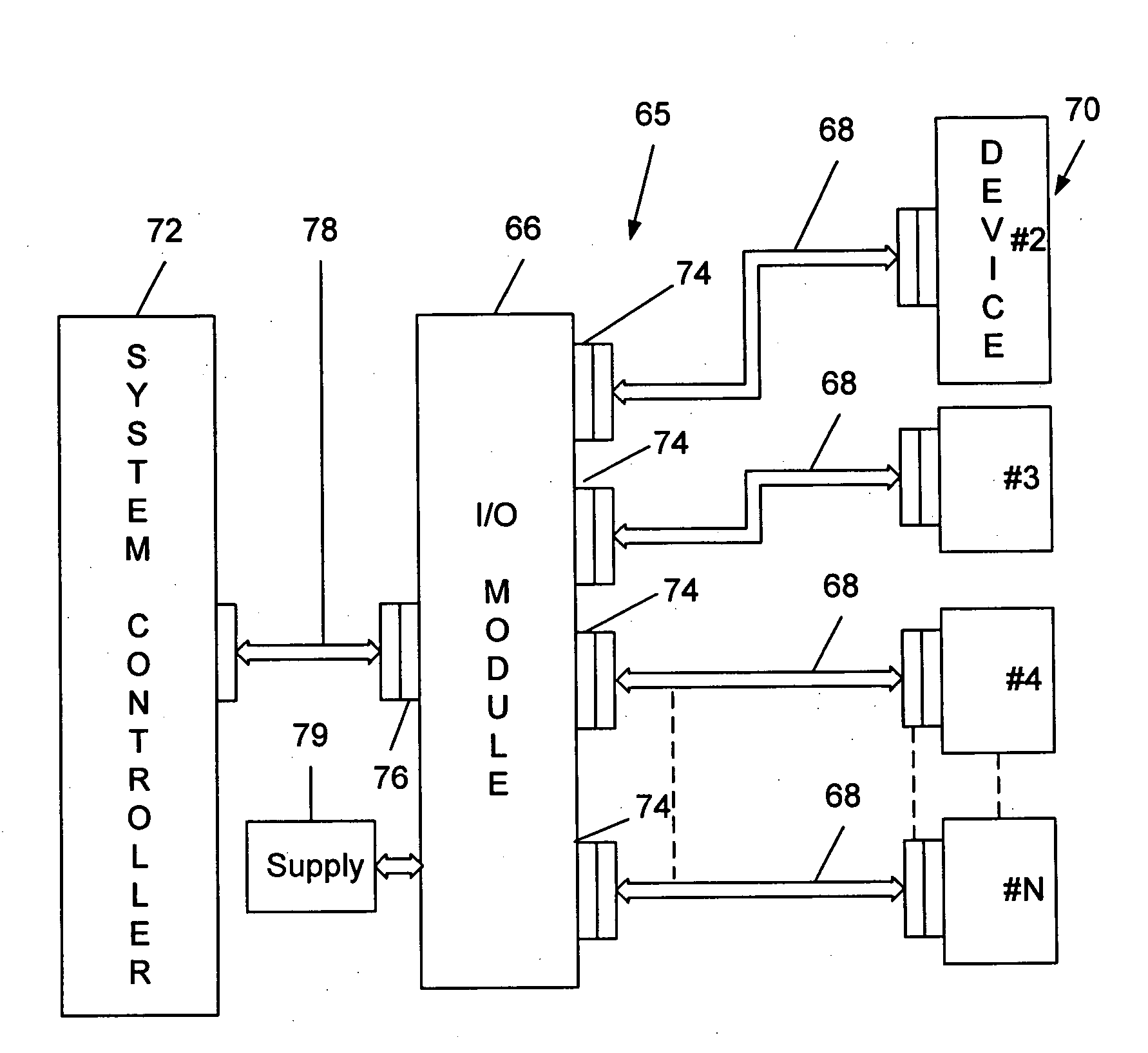

[0036] Referring now to FIG. 5 of the drawing, a block diagram is presented for illustration of the method and apparatus of a preferred embodiment of the present invention. The apparatus of the present invention includes a configurable input / output system 65 including an input / output module 66 and one or more cables 68. All of the cables 68 are preferably identical, but the present invention also includes variations in the cables 68. Each cable 68 includes one or more conductors. The I / O module 66 according to the present invention includes a microprocessor that is programmable for enabling a particular transmission of a signal between the module 66 and devices 70, and between the module 66 and a system controller 72. The module 66 also preferably includes one or more standard connectors 74 for connection to the standard cables 68. A connector 76 provides connection to a network (preferably Ethernet) 78 for communication between the module 66 and the system controller 72. The module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com