Device for checking fuel injectors and corresponding method

A fuel injector and injection valve technology, which is applied in the field of fuel injector devices, can solve the problem that the fuel injector cannot be inspected, etc., and achieve the effects of reliable and clear identification, simplified application or execution, and reduced wiring complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

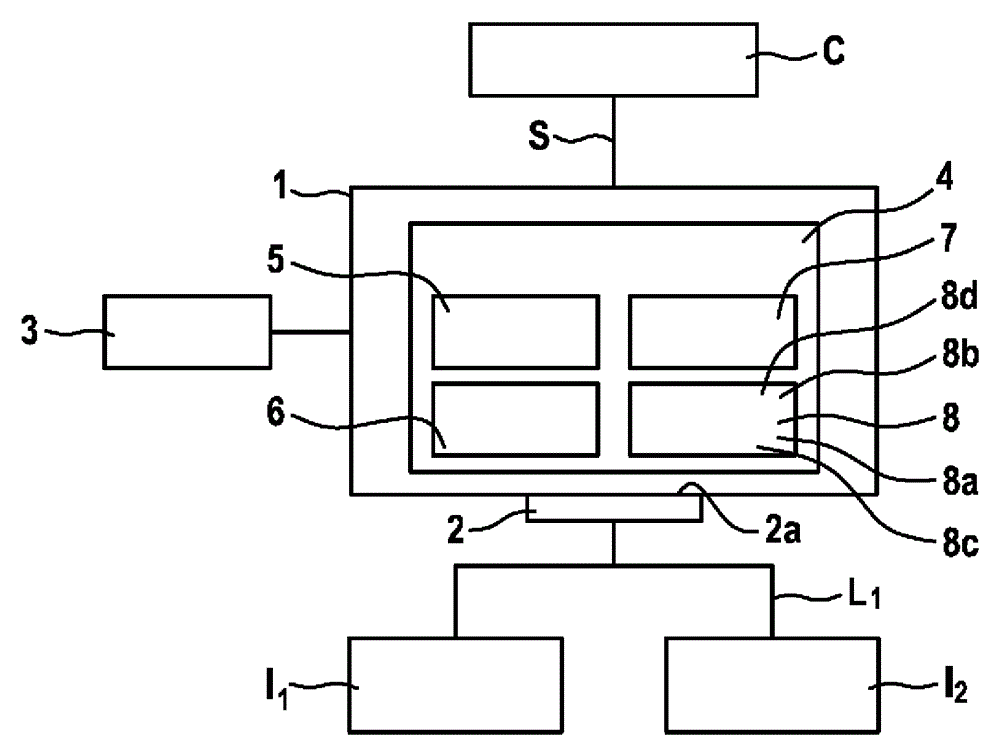

[0020] figure 1 A device for inspecting fuel injectors according to a first embodiment of the invention is shown.

[0021] exist figure 1 The reference numeral 1 in the figure indicates a device for inspecting piezoelectric fuel injectors. The device 1 is connected via a bidirectional interface S to an operating device in the form of a computer C on the one hand. In addition, an energy source 3 for operating the device 1 is connected to the device. The device 1 additionally comprises an outlet 2a designed to be connected to a fuel injector for two fuel injectors 1 1 , I 2 line L 1 mechanically and electrically coded plug 2. Plug 2 and corresponding mating connection 2a together with line L 1 Can be used here to connect piezoelectric and / or electromagnetic fuel injectors I 1 , I 2 . The connection 2 a interacts here with a test module 6 which indirectly detects the corresponding mechanical and electrical coding of the plug 2 and interacts with the microcontroller 5 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com