Energy recovery ventilator

a technology energy recovery, which is applied in the field of airtoair heat exchangers, can solve the problems of difficult for a single person to efficiently and easily install prior art energy recovery ventilator units, cost and cumbersome installation, etc., and achieve the effect of saving installation time and cost, saving time and cost, and easy installation of energy recovery ventilators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

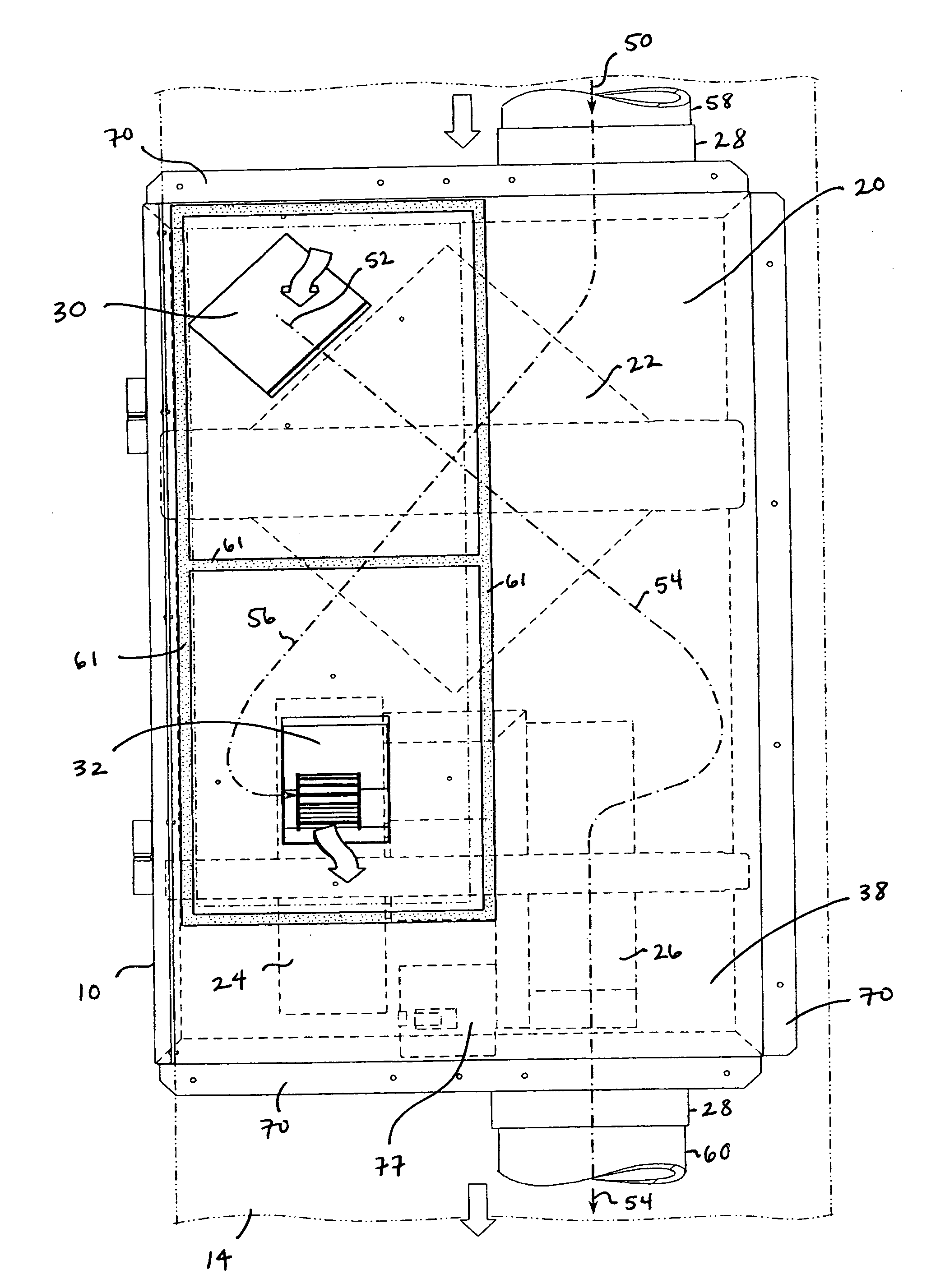

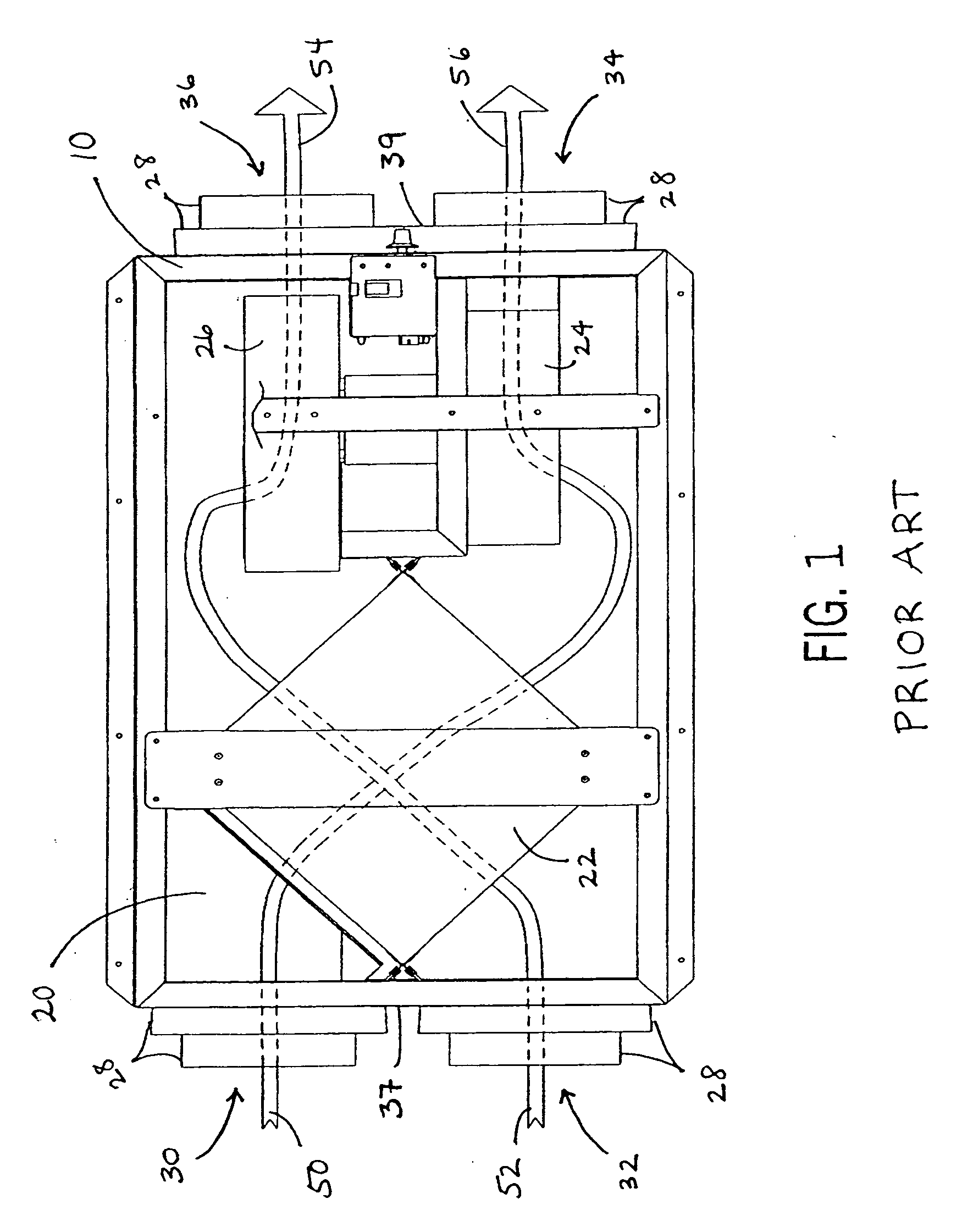

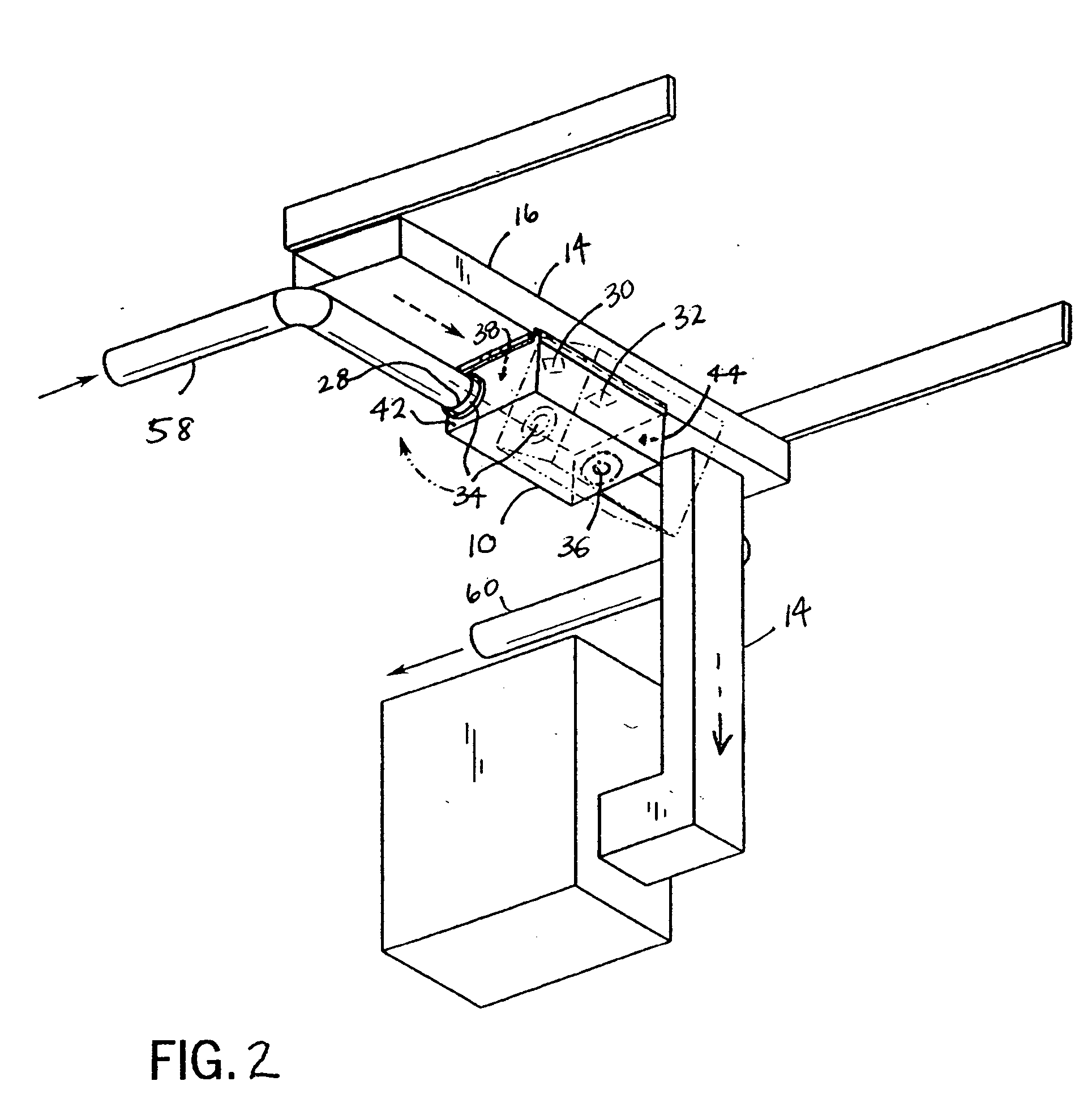

[0044] Referring again to the drawings, FIGS. 2, 3, 9 and 14 are isometric views of first, second, third and fourth embodiments of the present invention installed on a return air duct 14 of a heating or cooling system 12. In each of FIGS. 2, 3, 9, and 14, the energy recovery ventilator is shown as part of a ventilation system including a heating or cooling system 12, a heating or cooling mechanism 13, and a duct system including a return air duct 14. FIG. 2 shows a first embodiment, wherein the housing 10 is installed in a parallel orientation on the bottom of a horizontal section 16 of the return air duct 14. FIG. 3 shows a second embodiment, wherein the housing 10 is installed in a parallel orientation on the side of a vertical section 18 of a return air duct 14. FIG. 9 shows a third embodiment, wherein the housing 10 is installed in a perpendicular orientation on the bottom of a horizontal section 16 of a return air duct 14. FIG. 14 shows a fourth embodiment, wherein the housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com