Melt blown fiber structures for use in high strength wicks

a fiber structure and high-strength technology, applied in the direction of yarn, transportation and packaging, printing, etc., can solve the problems of early polyester filament-based attempts to reproduce these properties that were not acceptable, and achieve the effects of improving stiffness and robustness, simple, efficient and inexpensiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

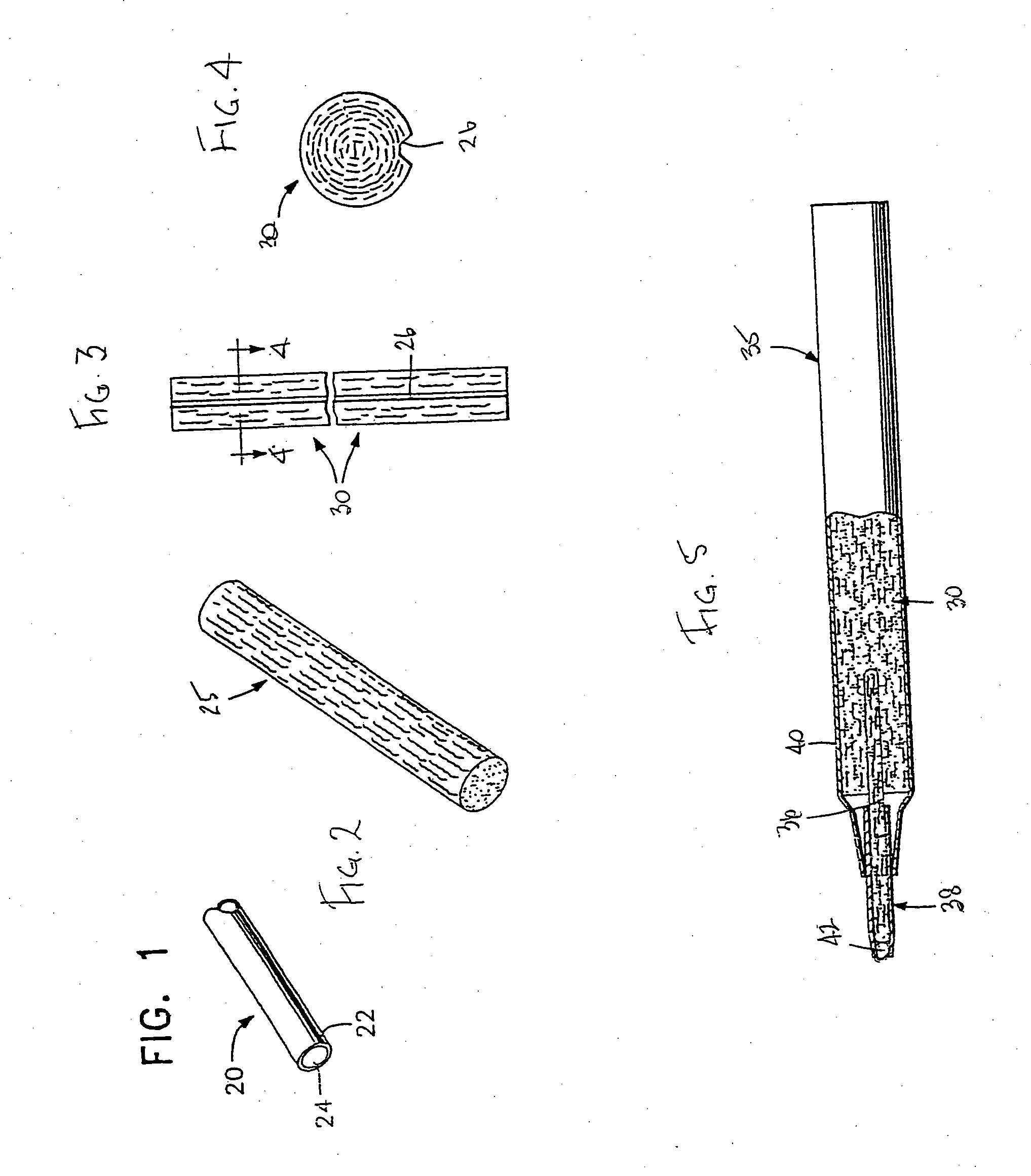

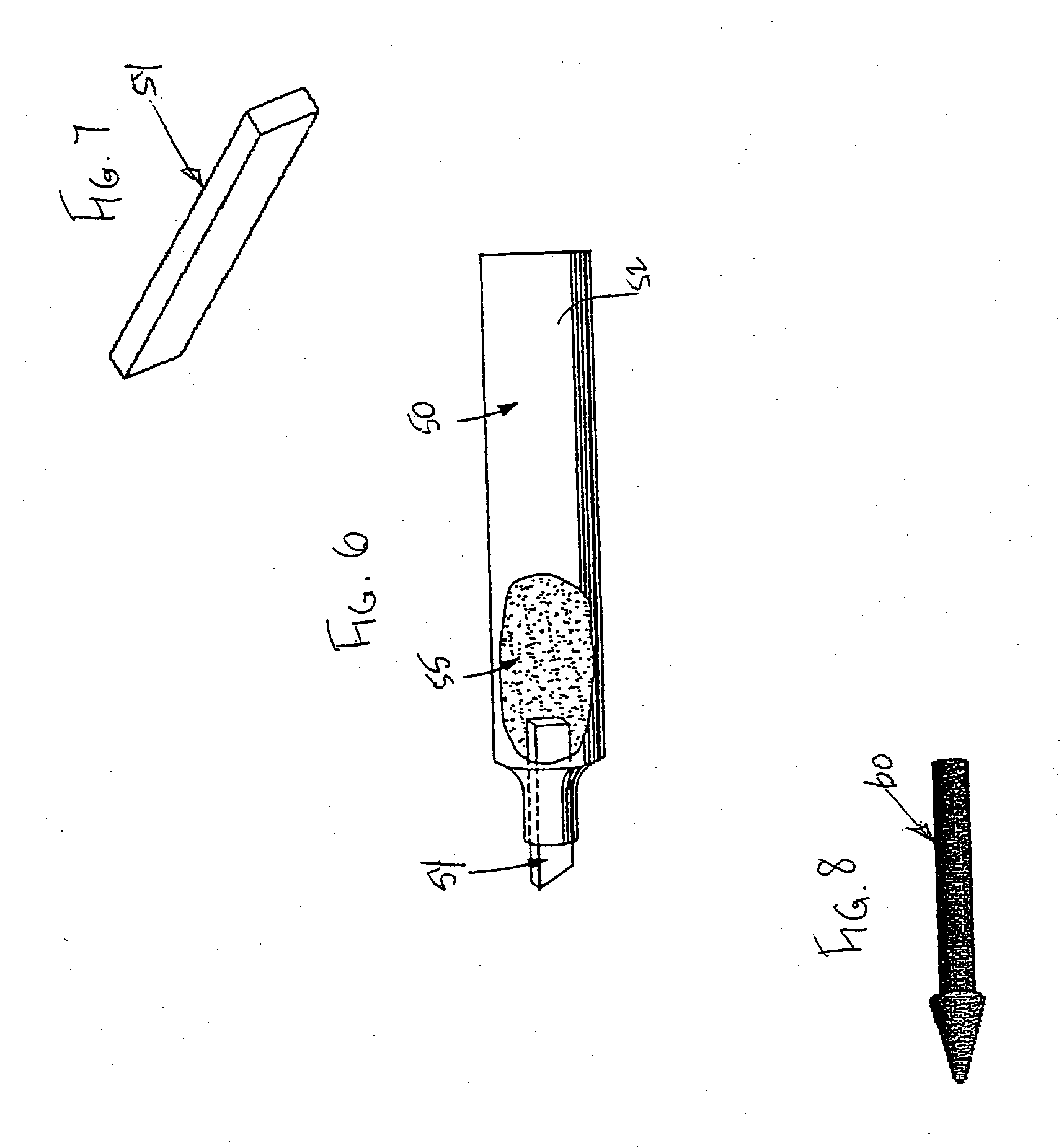

[0024] The instant inventive concepts are embodied in a bicomponent, sheath-core, melt blown, fiber as seen schematically, very enlarged, at 20 in FIG. 1 wherein the core 24 is formed of nylon 6,6 and the sheath 22 is formed of polyethylene terephthalate or a copolymer thereof.

[0025] As defined in the '766 patent, the term “bicomponent” as used herein refers to the use of two polymers of different chemical nature placed in discrete portions of a fiber structure. While other forms of bicomponent fibers are possible, the more common techniques produce either “side-by-side” or “sheath-core” relationships between the two polymers. The instant invention is concerned with the production of “sheath-core” bicomponent fibers wherein a sheath of polyethylene terephthalate or a copolymer thereof is spun to completely cover and encompass a core of nylon 6,6 or polybutylene terephthalate, preferably using a “melt blown” fiber process to attenuate the extruded fiber.

[0026] As defined in the '76...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| solvent resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com