Pallet constructed of rubber composite

a composite material and pallet technology, applied in the field of pallets, can solve the problems of more expensive production than wooden pallets, and none of these teach a non-wooden pallet constructed of a low-cost material, such as rubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

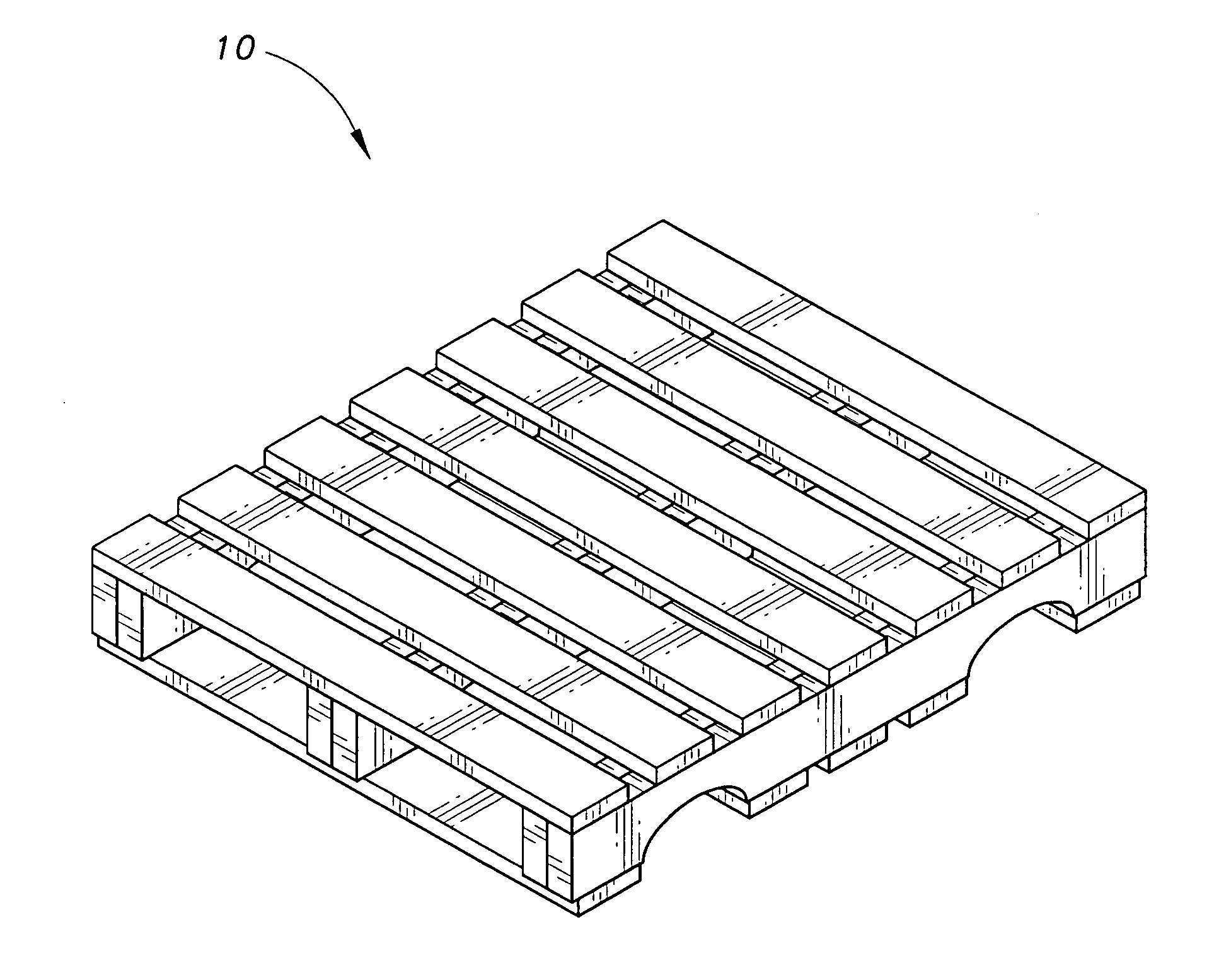

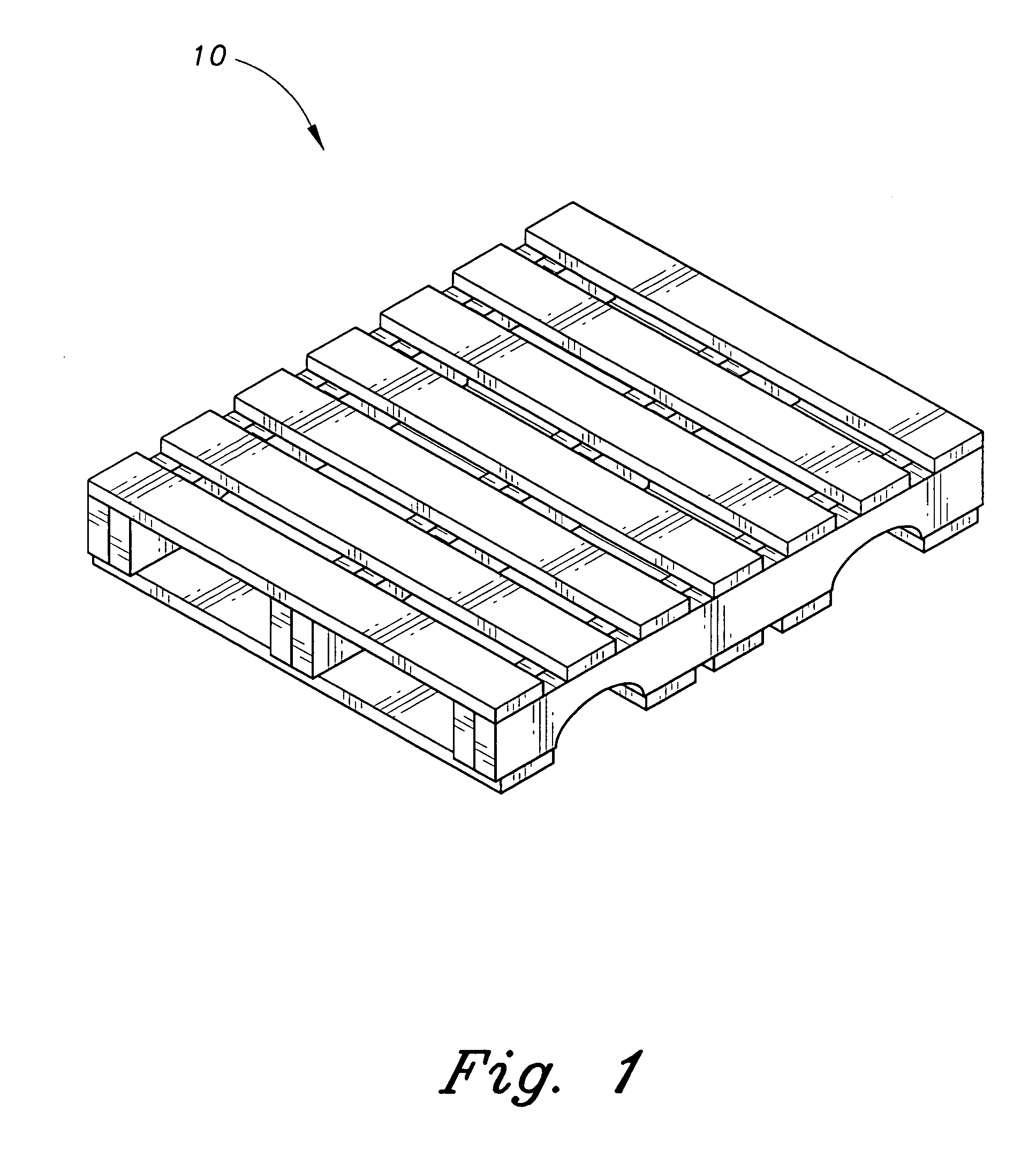

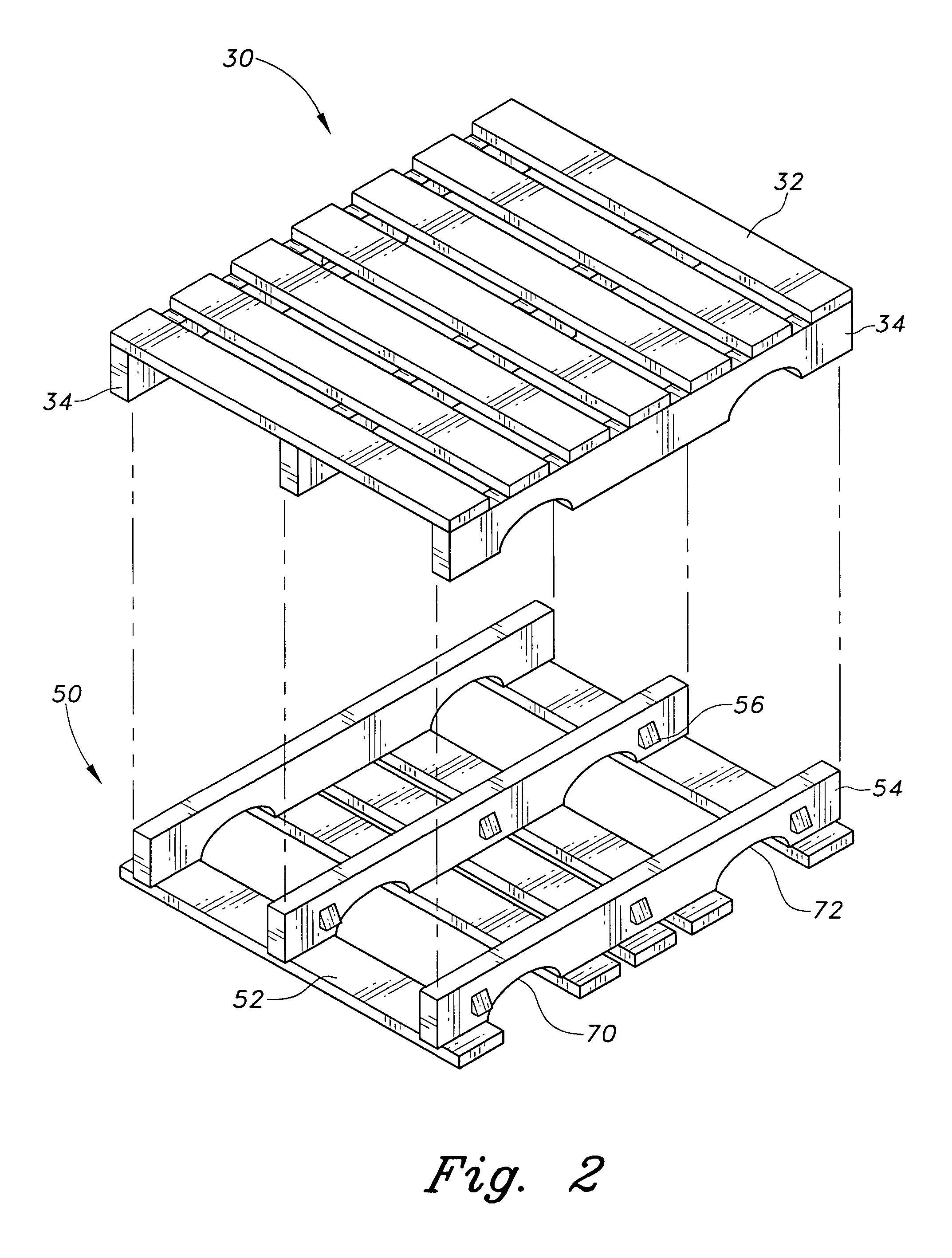

[0031] The present invention is a pallet constructed of rubber composite designated generally as 10 in the drawings. In appearance, it resembles a traditional American model wooden pallet as shown in FIG. 1. It is assembled from two injection-molded components including an upper member 30 and a lower member 50, as shown in FIG. 2.

[0032] The upper member 30 is molded such that it has a number of planks 32 attached to three crossbeams 34. The crossbeams 34, also known as stringers among pallet manufacturers, are substantially the same length, are substantially parallel to each other, and run front-to-back across the pallet 10. Likewise, the planks 32 are substantially the same length, are substantially parallel to each other, and run side-to-side across the pallet 10. The bottom side of each plank 32 is attached to the top edge of each of the crossbeams 34 with each plank 32 oriented substantially perpendicular to each crossbeam 34.

[0033] Similarly, the lower member 50 is also molde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com