Gear-driven shears provided with a curved plate a movable jaw

a technology of movable jaws and curved plates, applied in the direction of metal working apparatuses, secateurs, etc., can solve the problems of low material cost, troublesome blocking problem, lack of flexibility in structure, etc., and achieve the effect of less labor in operation, flexible and intensive use, and convenient use by users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

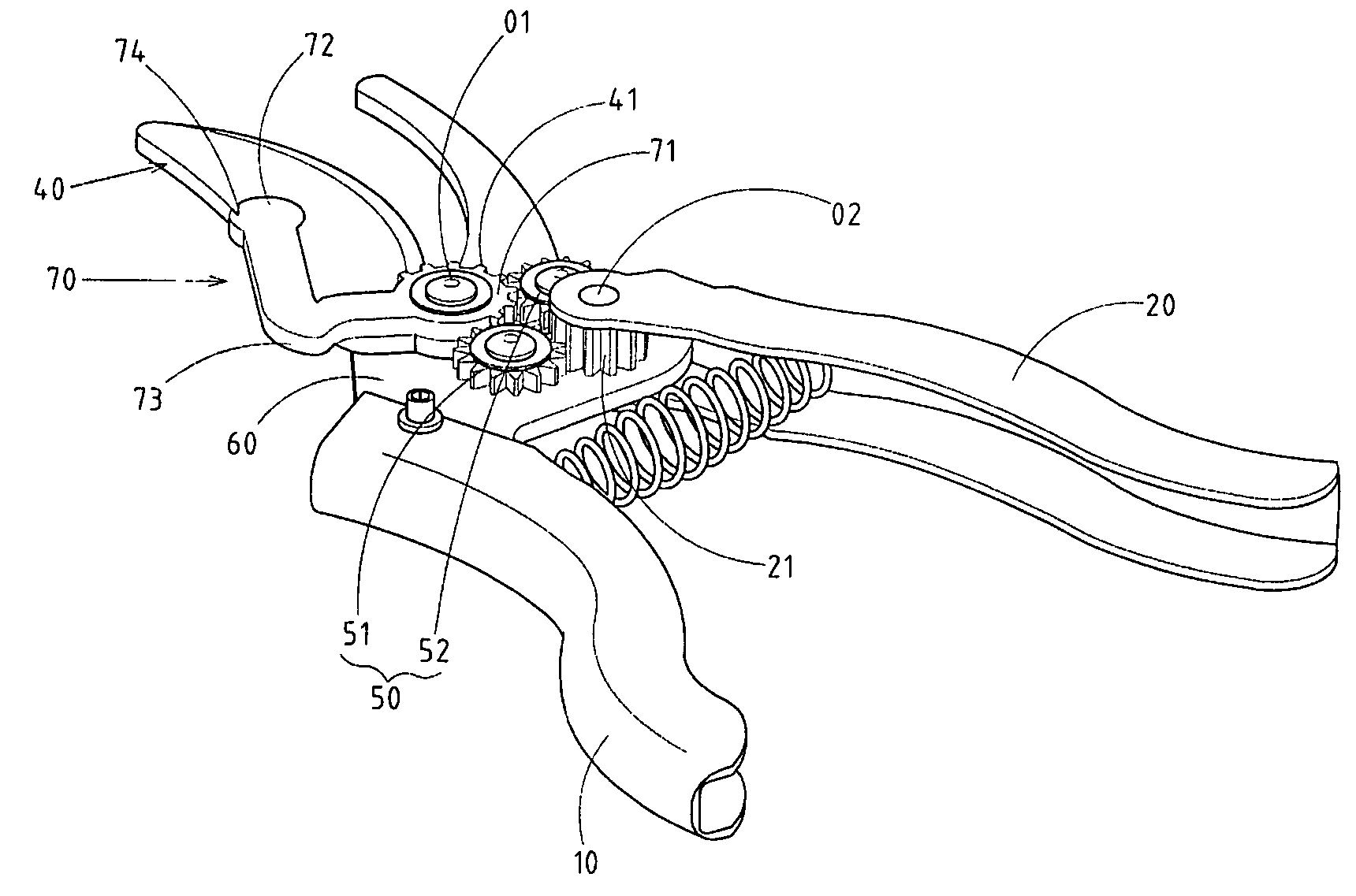

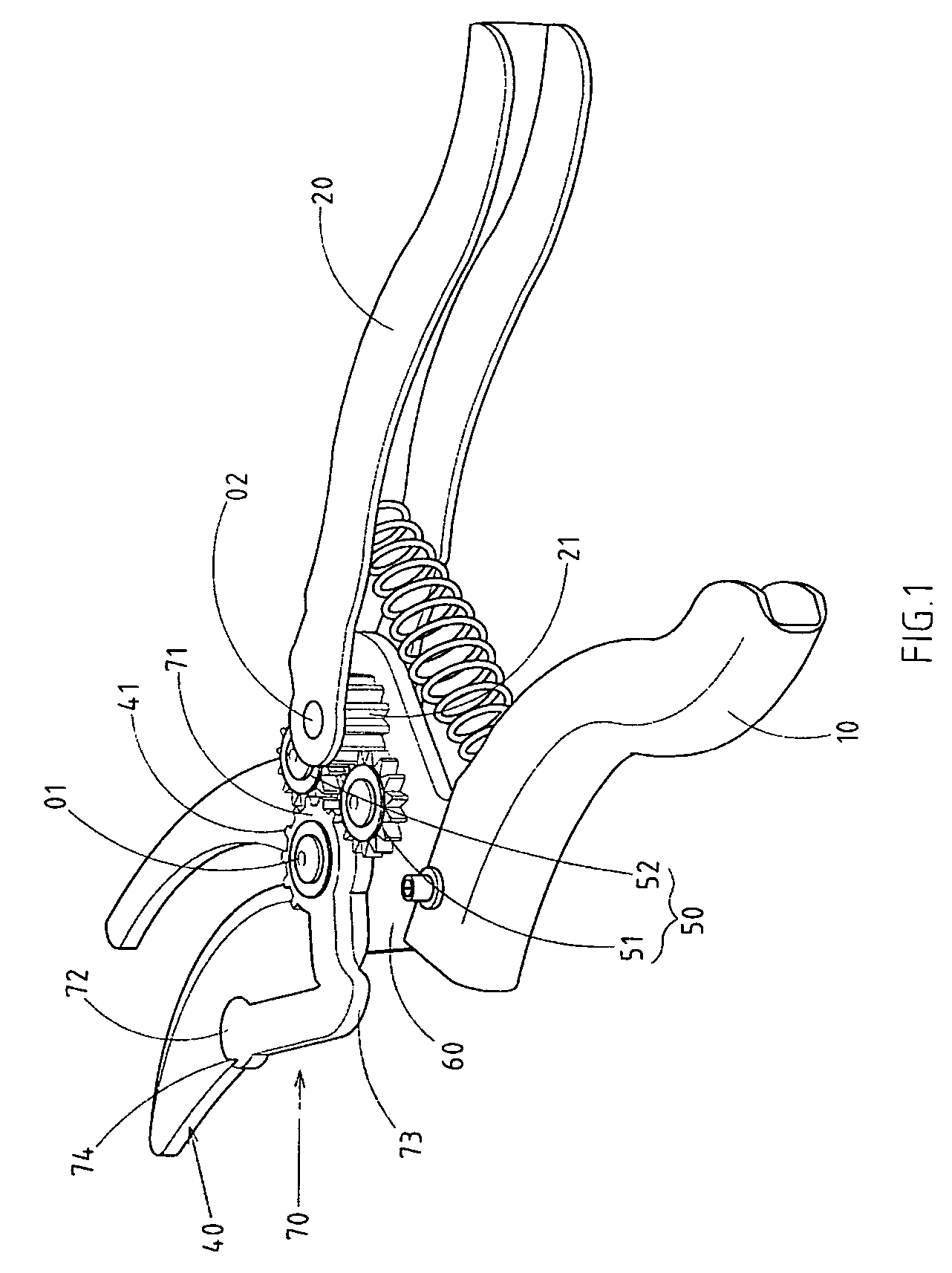

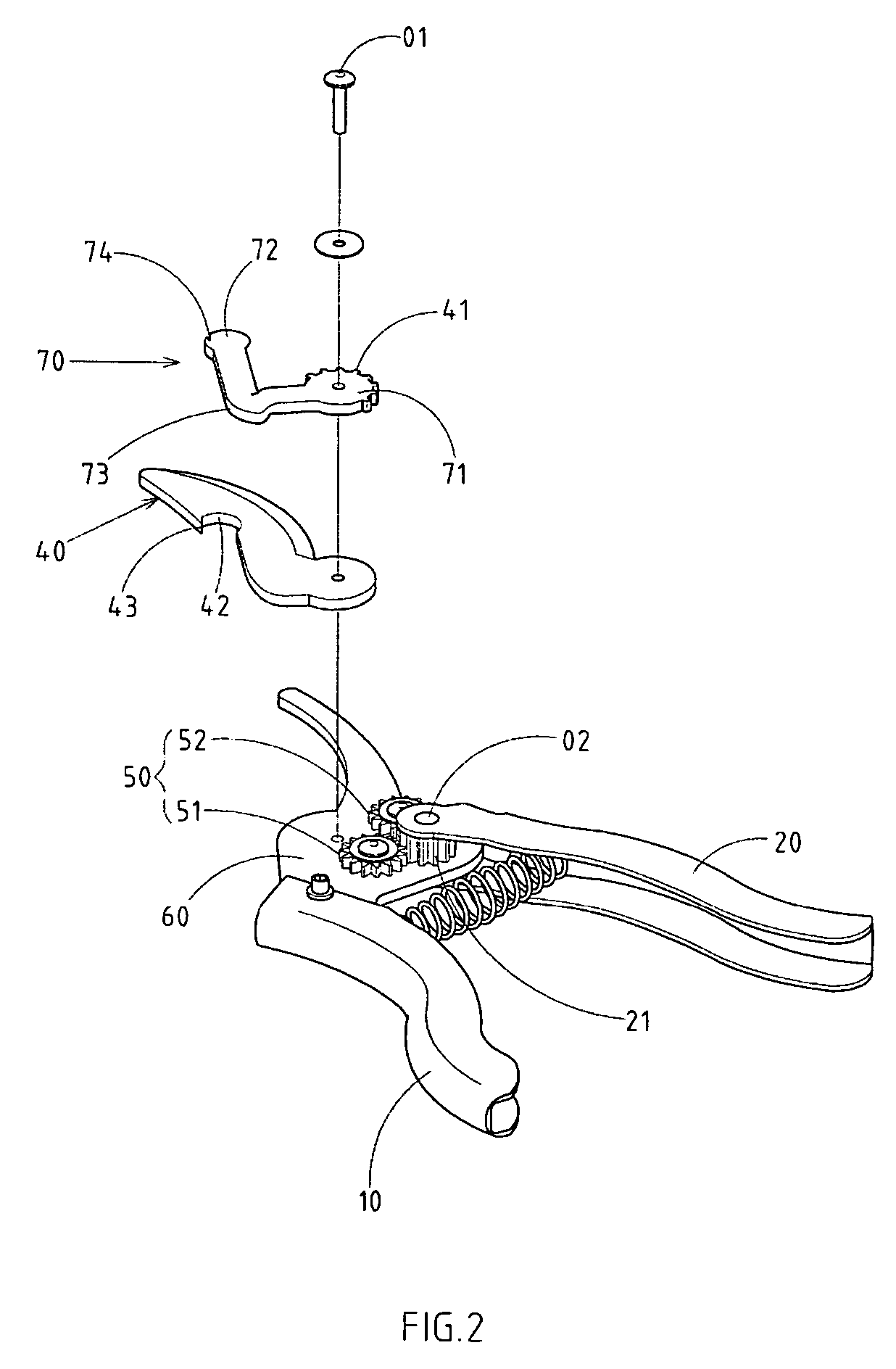

[0019] As shown in FIGS. 1-4, a gear-drive shear embodied in the present invention comprises: [0020] the first grip 10, the second grip 20, the fixed jaw 30, the movable jaw 40 and gear wheel module 50, among which, the fixed jaw and the first grip are connected together at a joint of plate assembly module 60 in the shape of ampliative plate. The corresponding ends of the movable jaw 40 and the second grip 20 are installed slanting on the plate assemble module 60 respectively to the corresponding first pivot axle 01 and second pivot axle 02. The corresponding ends of the movable jaw 40 and the second grip 20 are equipped with tooth edges 41, 21 respectively; The gear wheel module 50 consists of the first gear wheel 51 and the second gear wheel 52. These two groups of gears are installed between the corresponding ends of the movable jaw 40 and the second grip 20 on the plate assembly module 60, among which, the same sides of these two groups of gears 51, 52 jointly mesh with the toot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com