Method of creating fingerprint-imprinted jewelry

a technology of imprinting and jewelry, applied in the field of jewelry, can solve the problems of laborious methods of production of these jewelry pieces, limited people's ability to afford this type of personalization of their jewelry, and limited use of fingerprint imprinting technology, and achieve the effect of streamlining the process and increasing cost efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

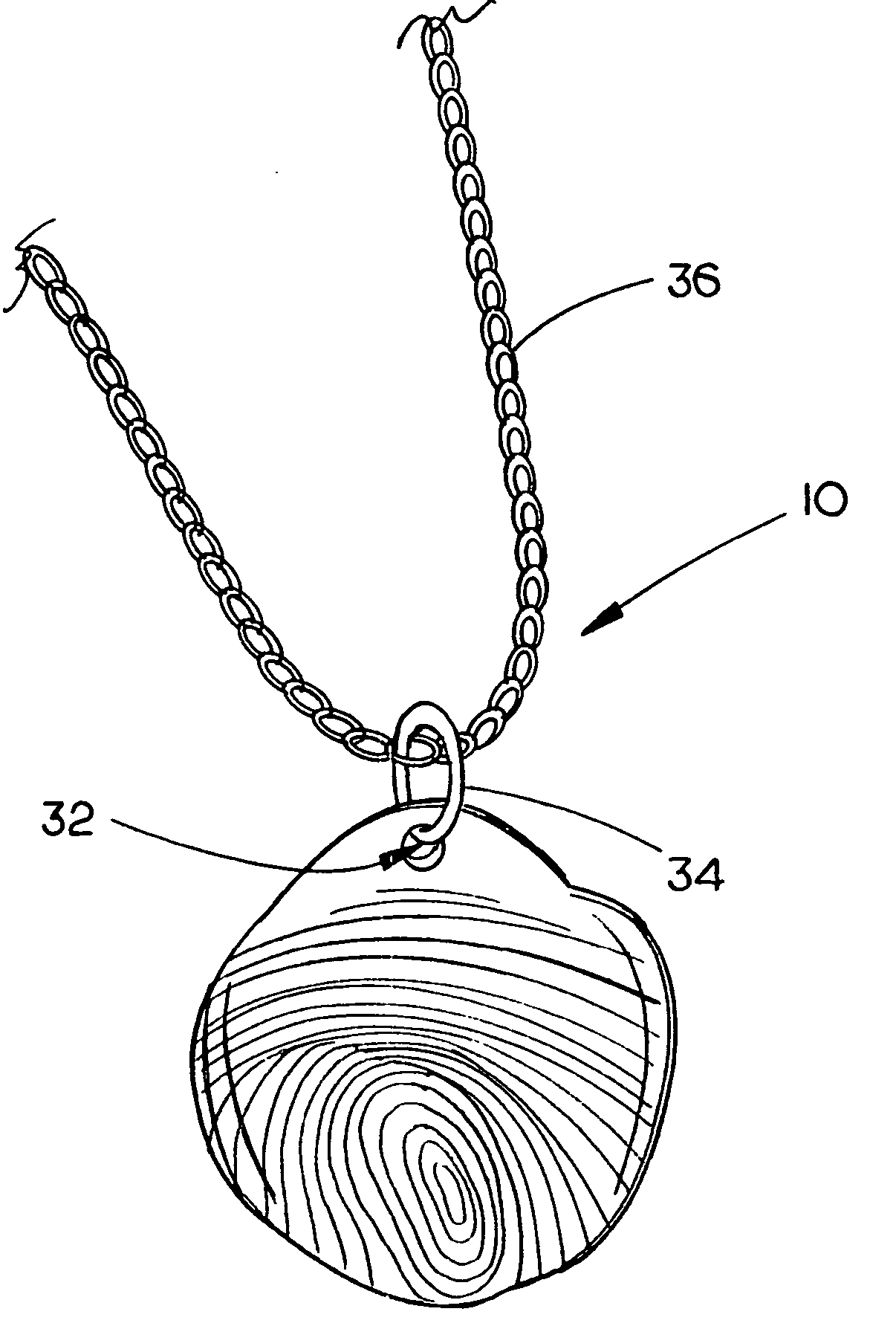

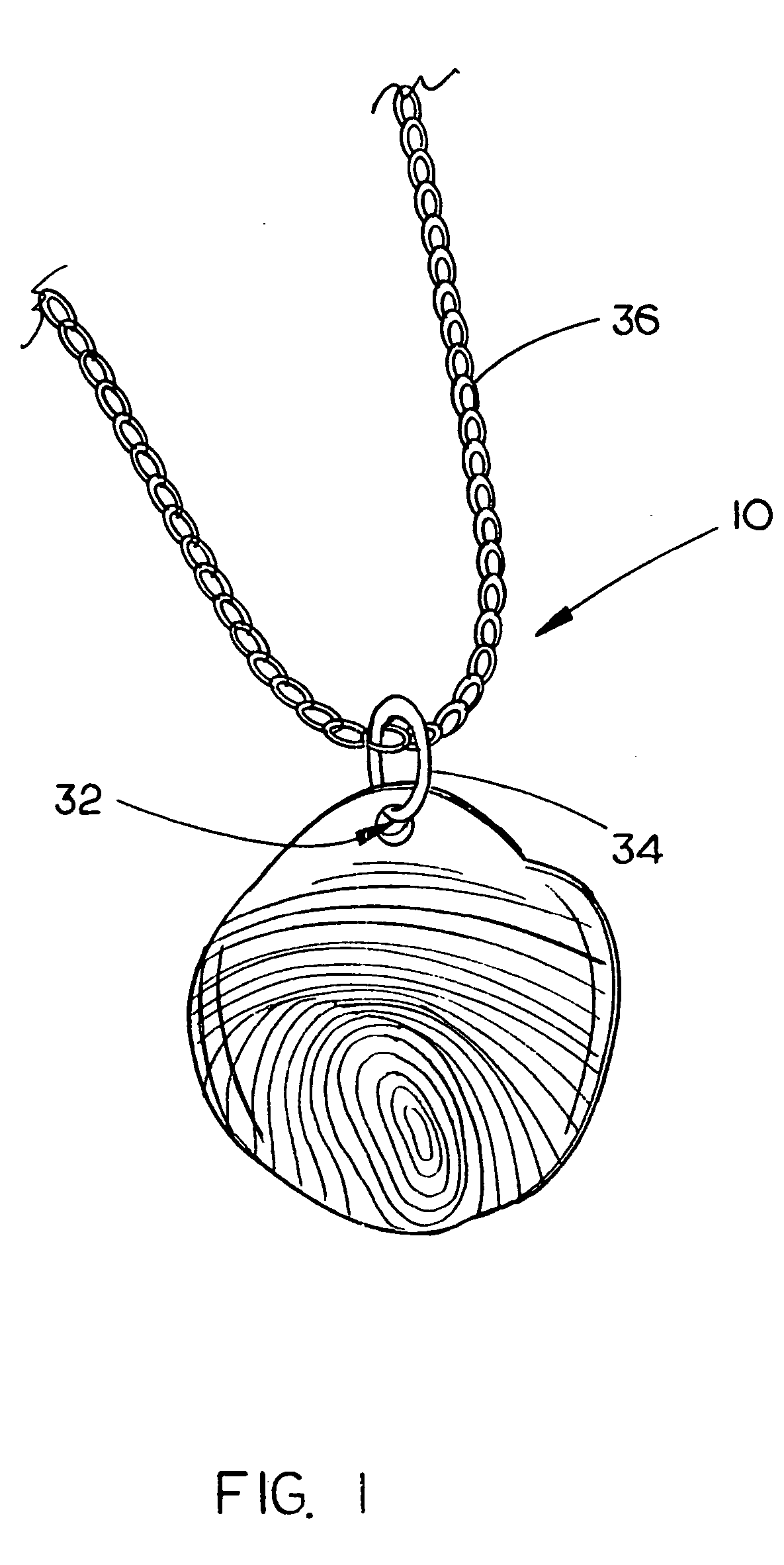

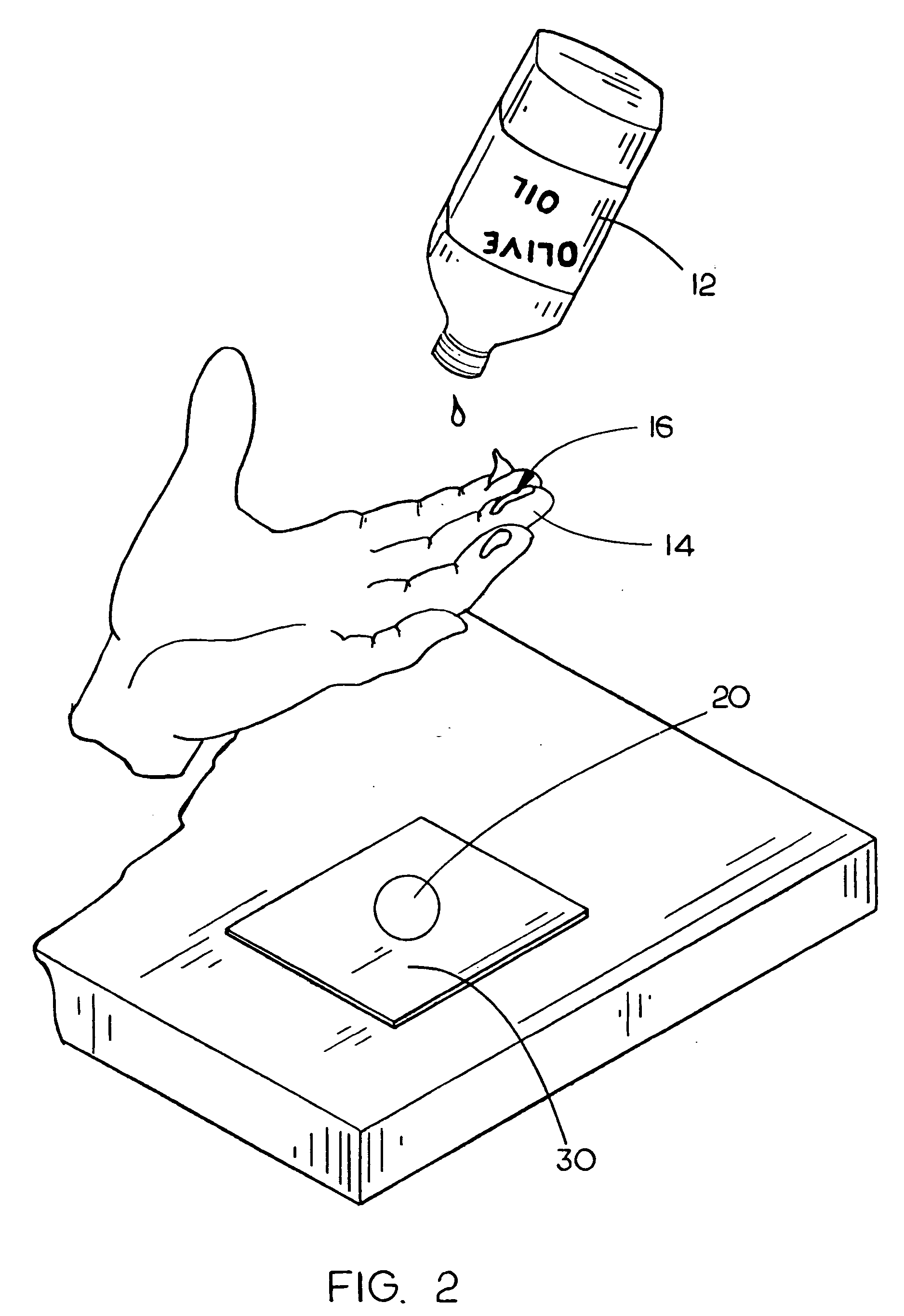

[0021] The method of forming the fingerprint display jewelry 10 of the present invention is shown best in FIGS. 1-6 as including the following steps. The user of the present method would first apply a slight amount of a lubricating oil such as olive oil 12 to his or her fingertips 14, as shown best in FIG. 2. Olive oil 12 is suggested for use with the method of the present invention due to its widespread availability, but is should be noted that many different types of lubricating liquids may be used with the present invention so long as they do not interact poorly with the precious metal clay or obscure the fingerprints 16 on the fingertips 14 of the individual using the present invention.

[0022] The user of the method of the present invention would then take a small amount of precious metal clay (PMC) and form a generally spherical ball 20, as shown in FIG. 2. Precious metal clay or PMC is a commercially available clay-based material which includes an amount of precious metal, usu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com