Quick assembly adjustable shelf and drawer system

a shelf and drawer system technology, applied in the field of shelves and drawer systems and brackets, can solve the problems of limited ability to withstand shear forces, fatigue of supporting walls, and failure of supporting walls, and achieve the effects of minimizing moments and shear forces, quick adjustment of shelves, and high load bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

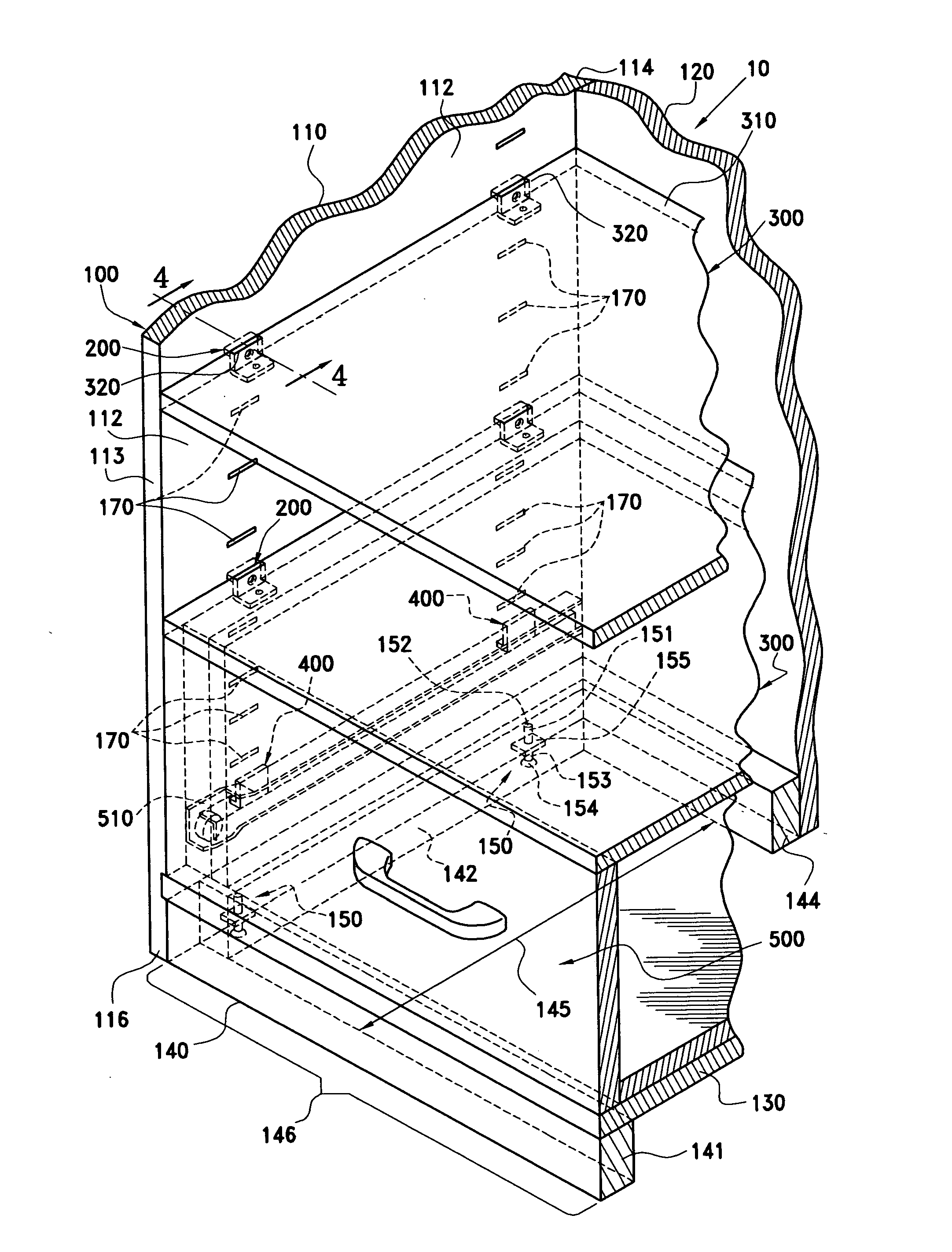

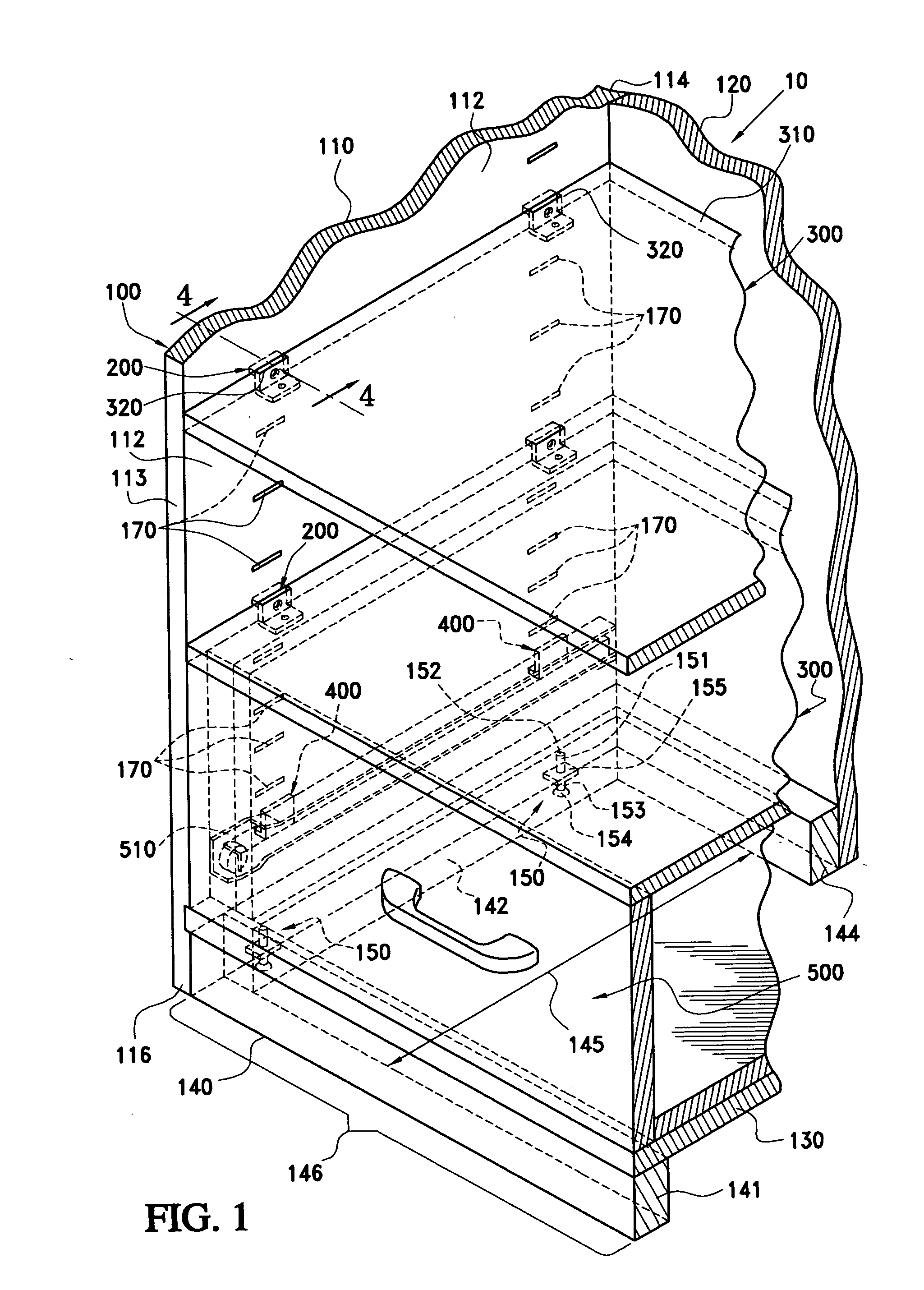

[0031]FIG. 1 is a perspective view of a system 10, which is an exemplary embodiment of a shelf and drawer system made in accordance with this invention. The system 10 is specifically designed to be used in a garage; however, the system 10 may also be used in any environment where shelves and drawers are needed, such as but not limited to closets, kitchens, offices, bathrooms, etc. The system 10 includes a cabinet 100, a plurality of support devices 200, a plurality of shelves 300, a plurality of support brackets 400 and a plurality of drawers 500.

[0032] The system 10, as shown in FIG. 1, is operably configured to provide a means to adjust the placement of the shelves 300 and the drawers 500 by a user in minimum time without sacrificing load bearing capacity. The cabinet 100 is operably configured to receive the support devices 200 and the support brackets 400. The support devices 200, or shelf brackets, are operably configured to removably attach the shelves 300 to the cabinet 100....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com