System for improving thermal stability of copper damascene structure

a technology of damascene and thermal stability, which is applied in the direction of semiconductor/solid-state device manufacturing, basic electric elements, electric devices, etc., can solve the problems of device failure, copper is very difficult to etch in the semiconductor process flow, circuit generates numerous challenges to the semiconductor manufacturing process, etc., and achieves the effect of adding excessive costs or procedures and being more reliabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] It should be understood that the principles and applications disclosed herein may be applied to a wide range of semiconductor device fabrication processes. For purposes of explanation and illustration, the present invention is hereafter described in reference to several specific embodiments of methods of semiconductor device fabrication. The present invention, however, is equally applicable in any number of fabrication processes that might benefit from the present invention.

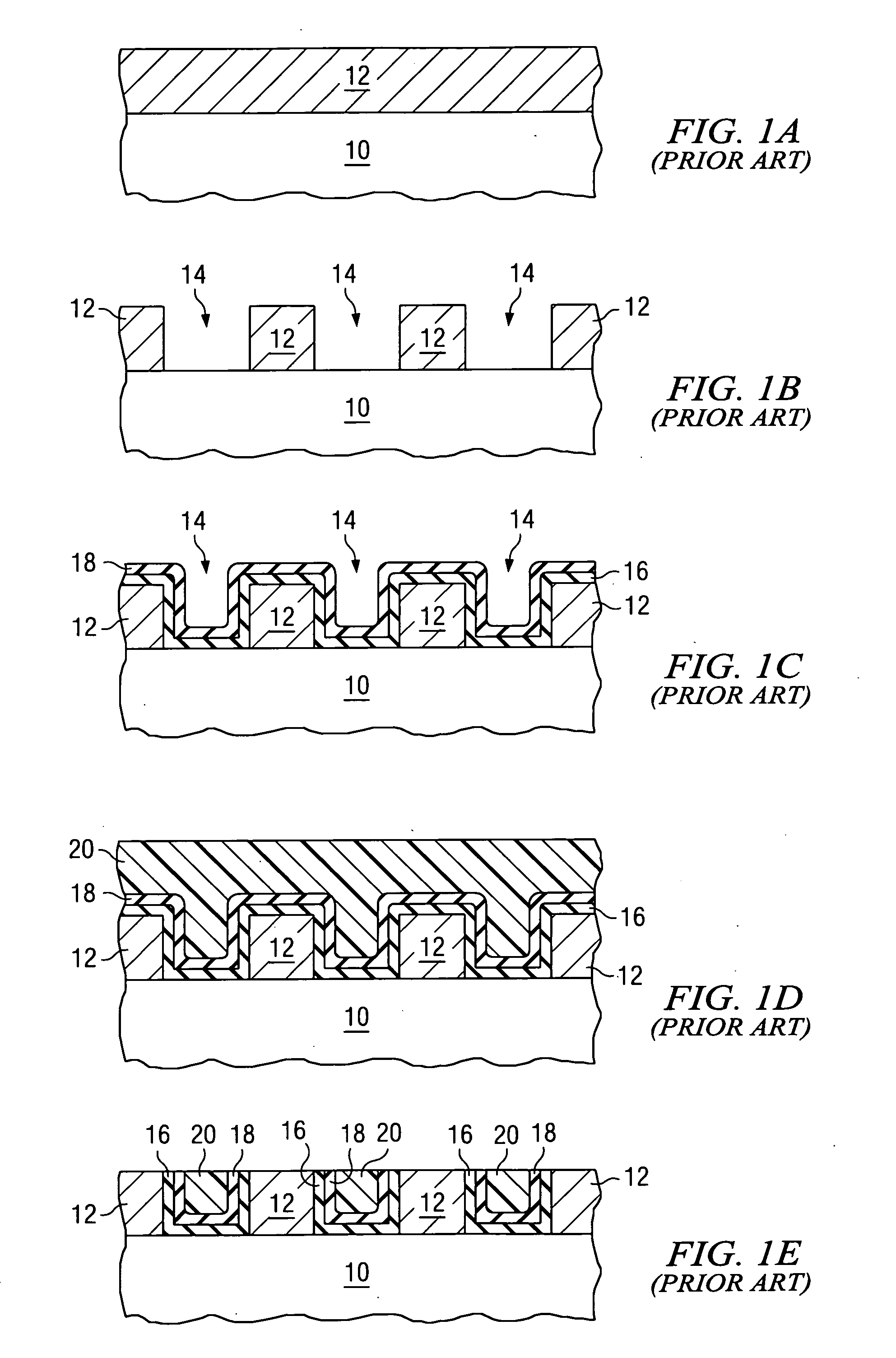

[0017] Turning now to the present invention as depicted in FIGS. 2A-2D, a copper interconnect structure may be formed, for example, generally according to the procedures depicted in and described with reference to FIGS. 1A-1D above. As depicted in FIG. 2A, the interlevel dielectric 102 is formed over the semiconductor body 100. The interlevel dielectric 102 is then patterned and etched to remove the dielectric material from the areas 118 (not shown) where interconnect lines are desired. The barrier layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com