Pallet jack stop

a pallet jack and stop technology, applied in the direction of machine supports, braking systems, furniture parts, etc., can solve the problems of heavy pallet jacks, extensive property damage, serious injuries to warehouse workers and other personnel, etc., and achieve the effect of reducing the weight of the device and the amount of material required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

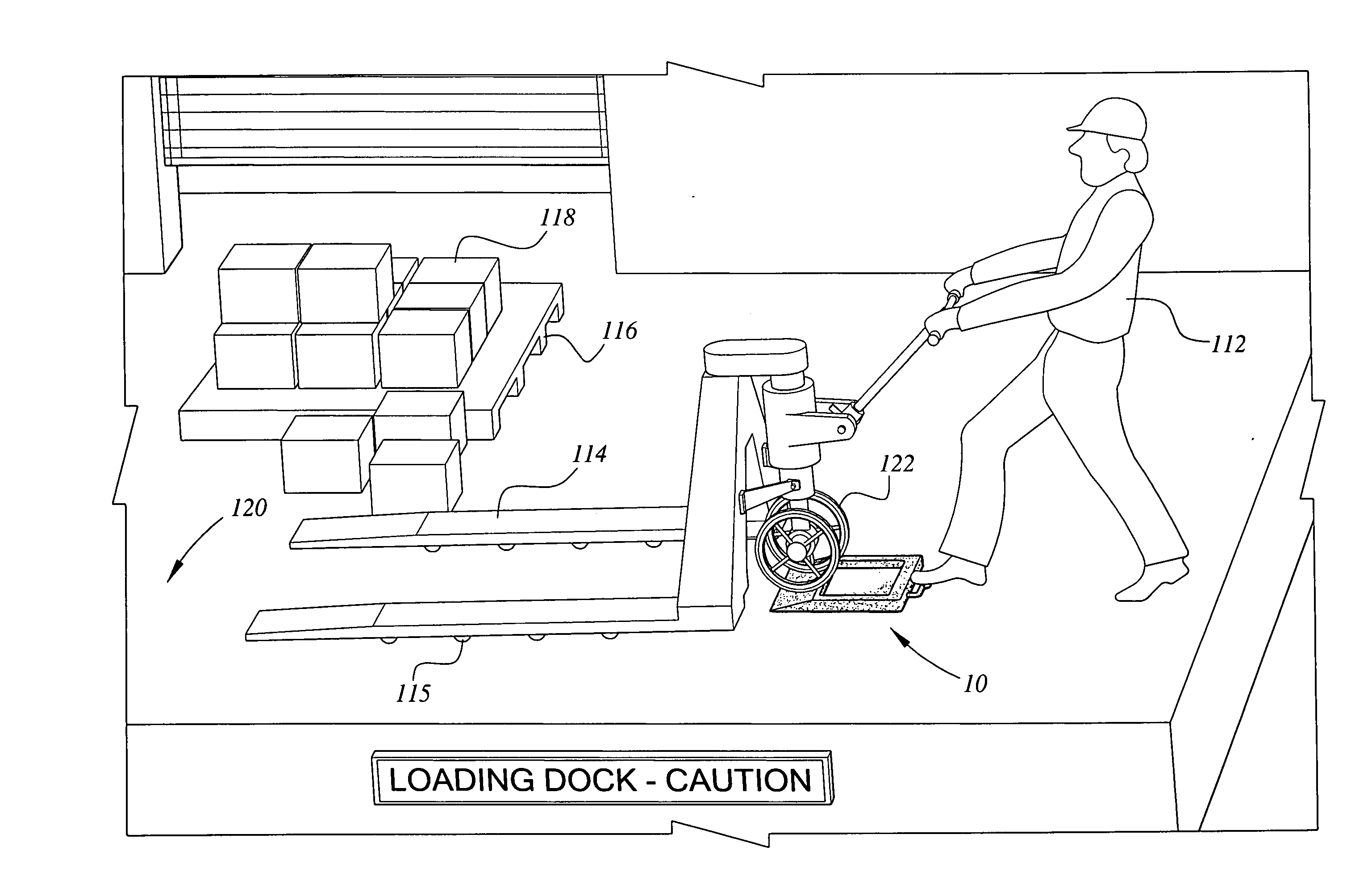

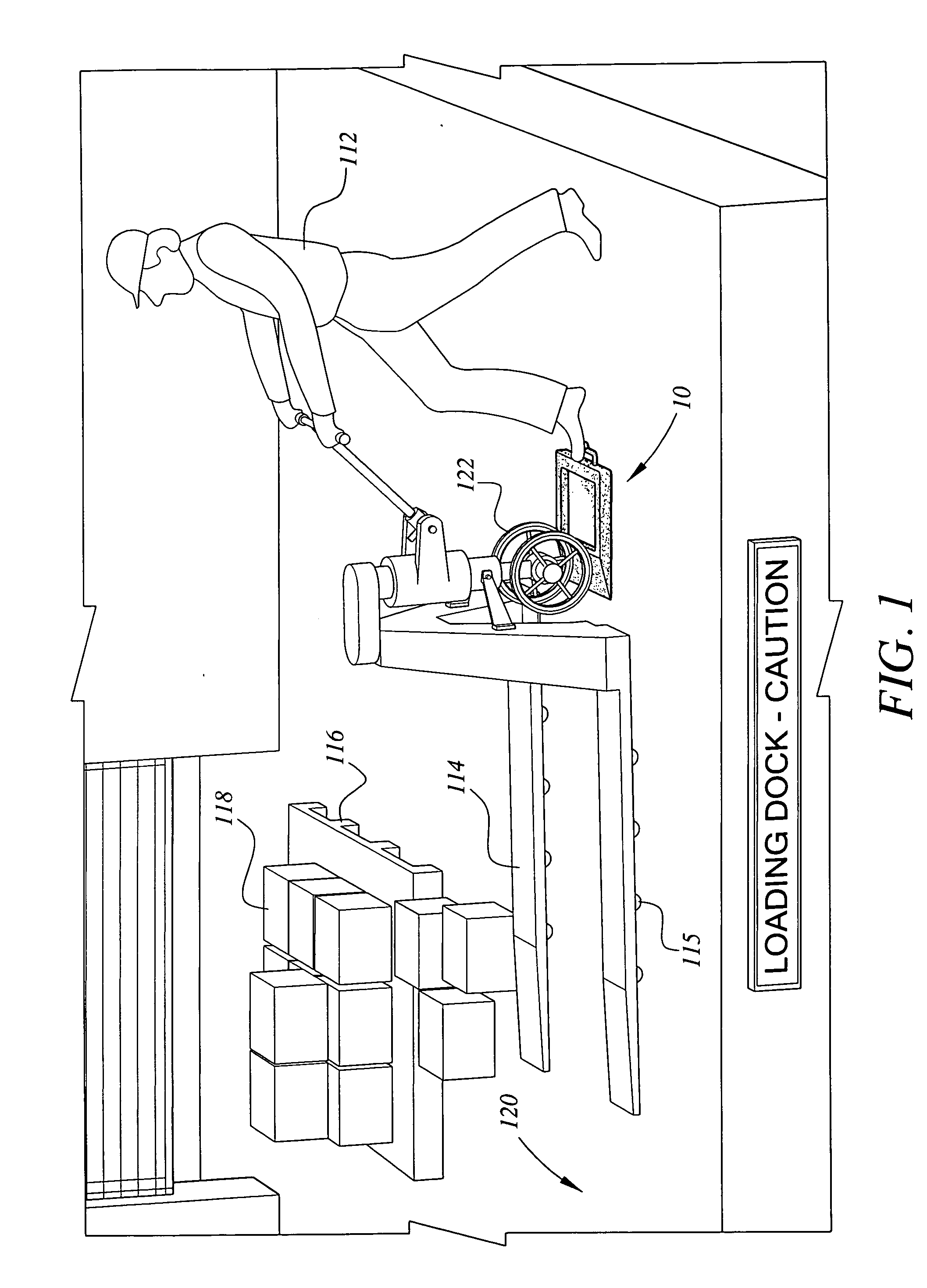

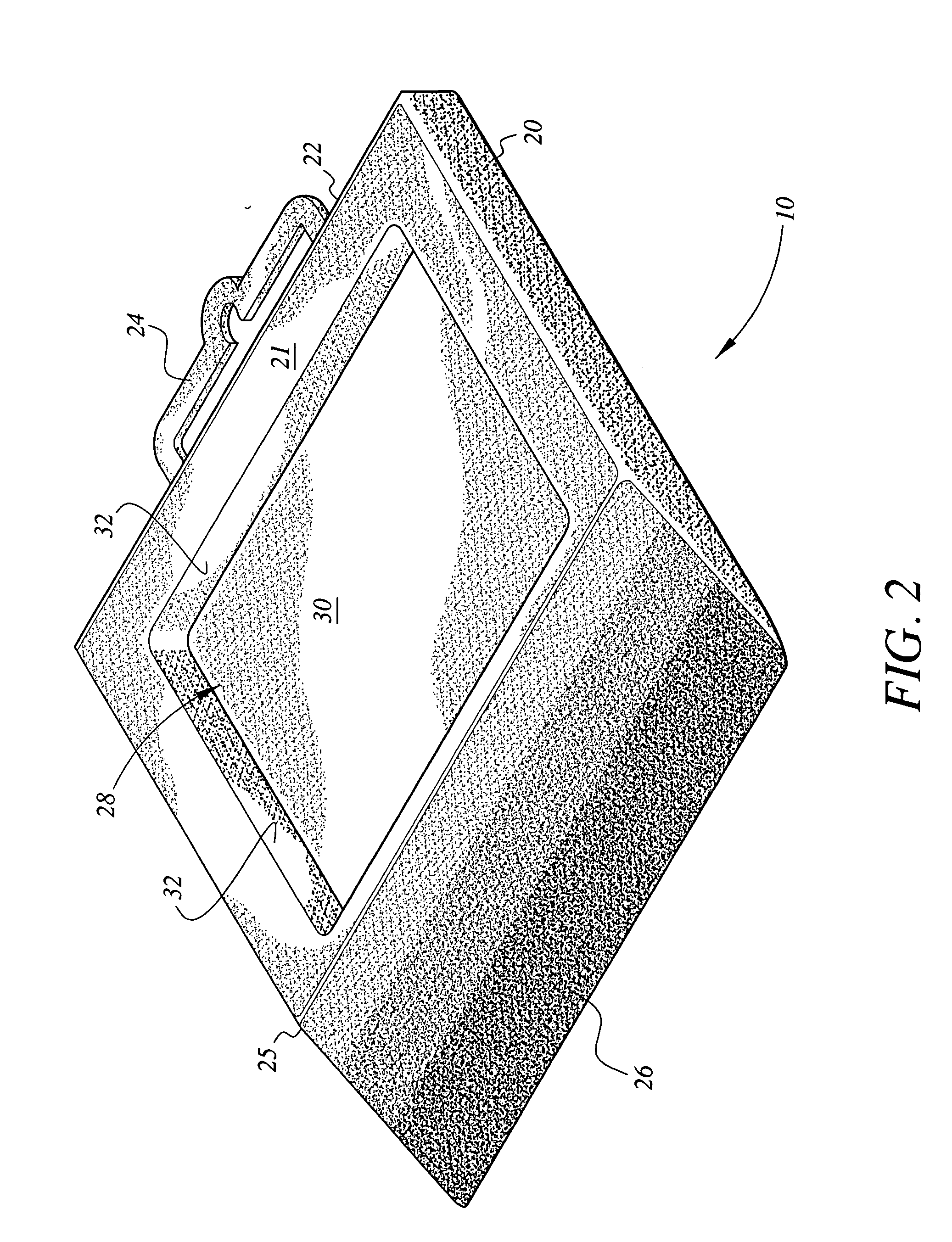

[0032] The present invention is a pallet jack stop, designated generally as 10 in the drawings. The pallet jack stop 10 is designed to immobilize the pivot wheel(s) 122 on a warehouse style pallet jack 114, as shown in FIG. 1. Referring first to FIGS. 2 and 3, the pallet jack stop 10 comprises a rectangular body 20 made from dense rubber (natural or synthetic) or similar material having a top side 21 and a bottom surface 40, and a ramp end 25 and a handle end 22 opposite the ramp end 25. In the illustrated embodiment, a handle 24 extends from the handle end 22, and may be formed integrally with the body 20 or may be made as a separate piece and joined to the body of the pallet jack stop 10 by adhesives, ultrasonic welding, heat welding, or other joinery techniques conventionally known in the art. Optionally, the handle 24 may be positioned elsewhere on the body 20 of the pallet jack stop 10, or may be eliminated entirely.

[0033] A sloping ramp portion extends from the ramp end 25, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com