Status flags in a system of electronic pyrotechnic devices such as electronic detonators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

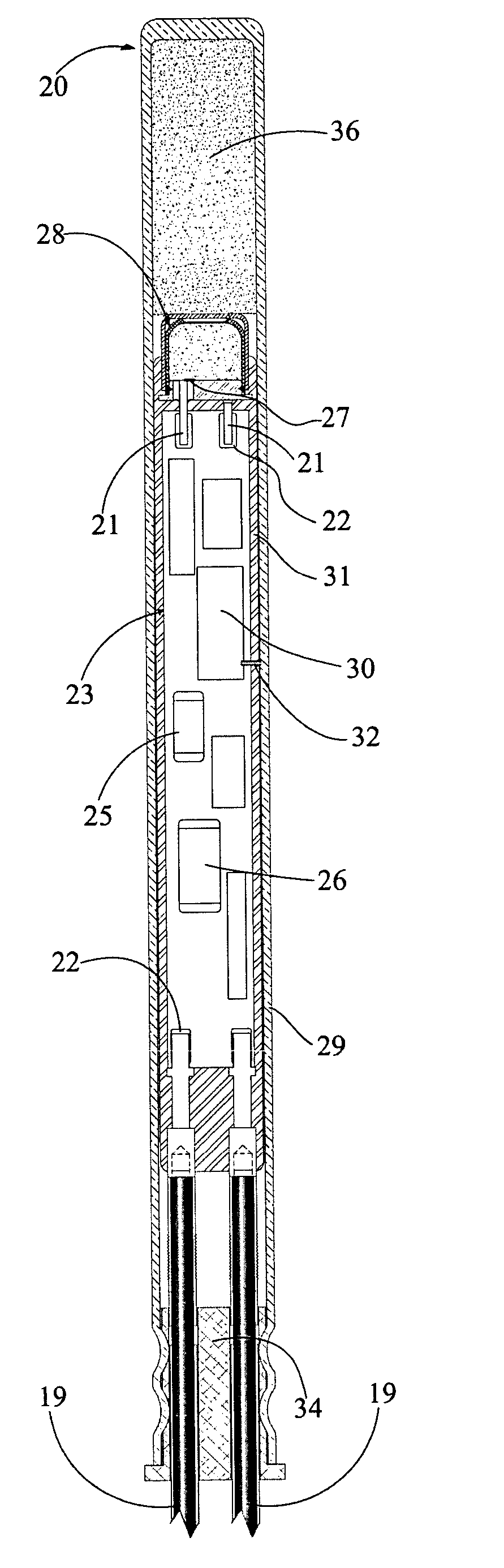

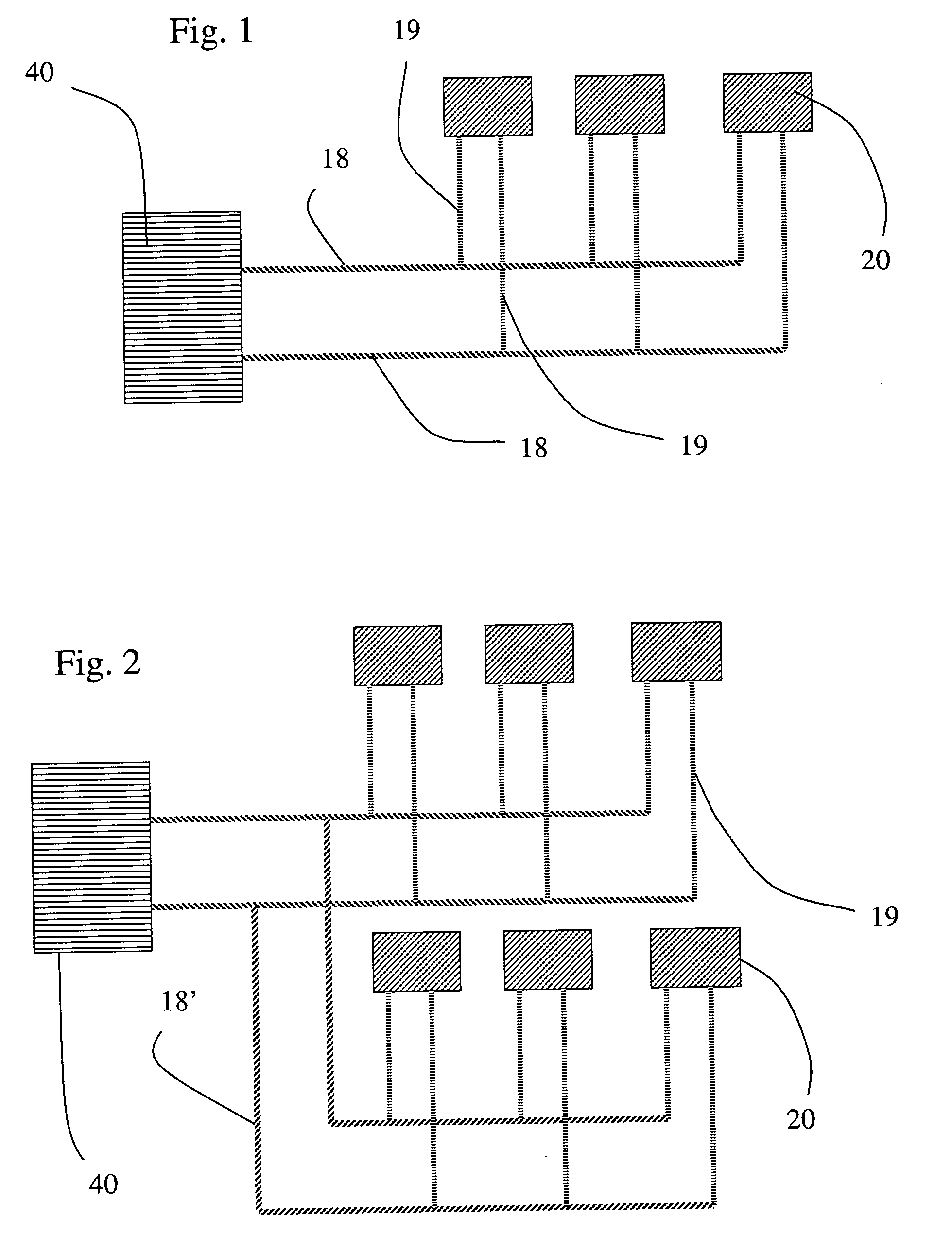

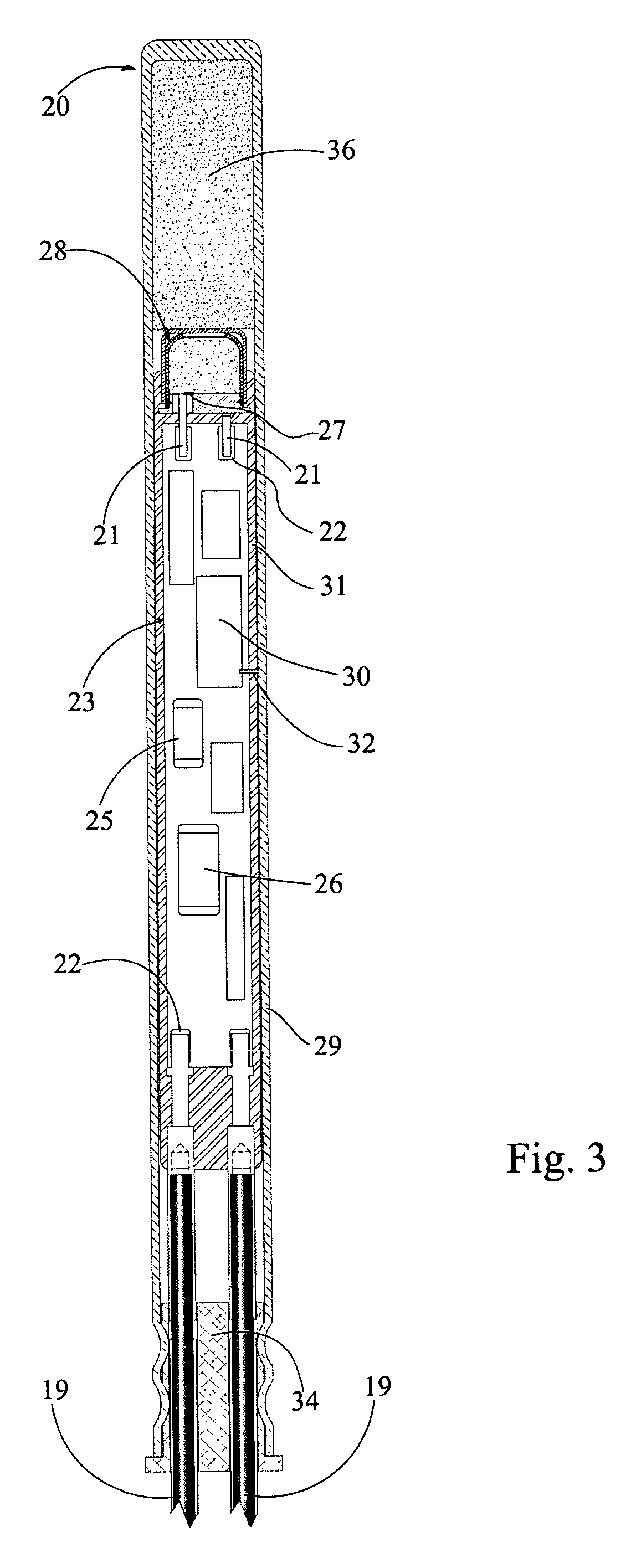

[0020] To describe the present invention with reference to the details of a particular preferred embodiment, it is noted that the present invention may be employed in an electronic system comprising a network of slave devices, for example, an electronic blasting system in which the slave devices are electronic detonators. As depicted in FIG. 1, one embodiment of such an electronic blasting system may comprise a number of detonators 20, a two-line bus 18, leg wires 19 including connectors for attaching the detonator to the bus 18, a logger (not shown), and a blasting machine 40. The detonators 20 are preferably connected to the blasting machine 40 in parallel (as in FIG. 1) or in other arrangements including branch (as in FIG. 2), tree, star, or multiple parallel connections. A preferred embodiment of such an electronic blasting system is described below, although it will be readily appreciated by one of ordinary skill in the art that other systems or devices could also be used, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com