Perforating connector with sterile connection

a technology of perforating connectors and sterile connections, which is applied in the direction of diagnostics, packaging goods, injection needles, etc., can solve the problems of high risk of injury to the personnel using the connectors, pollute the needles, etc., and achieve the effect of facilitating the manipulation of the perforating connectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

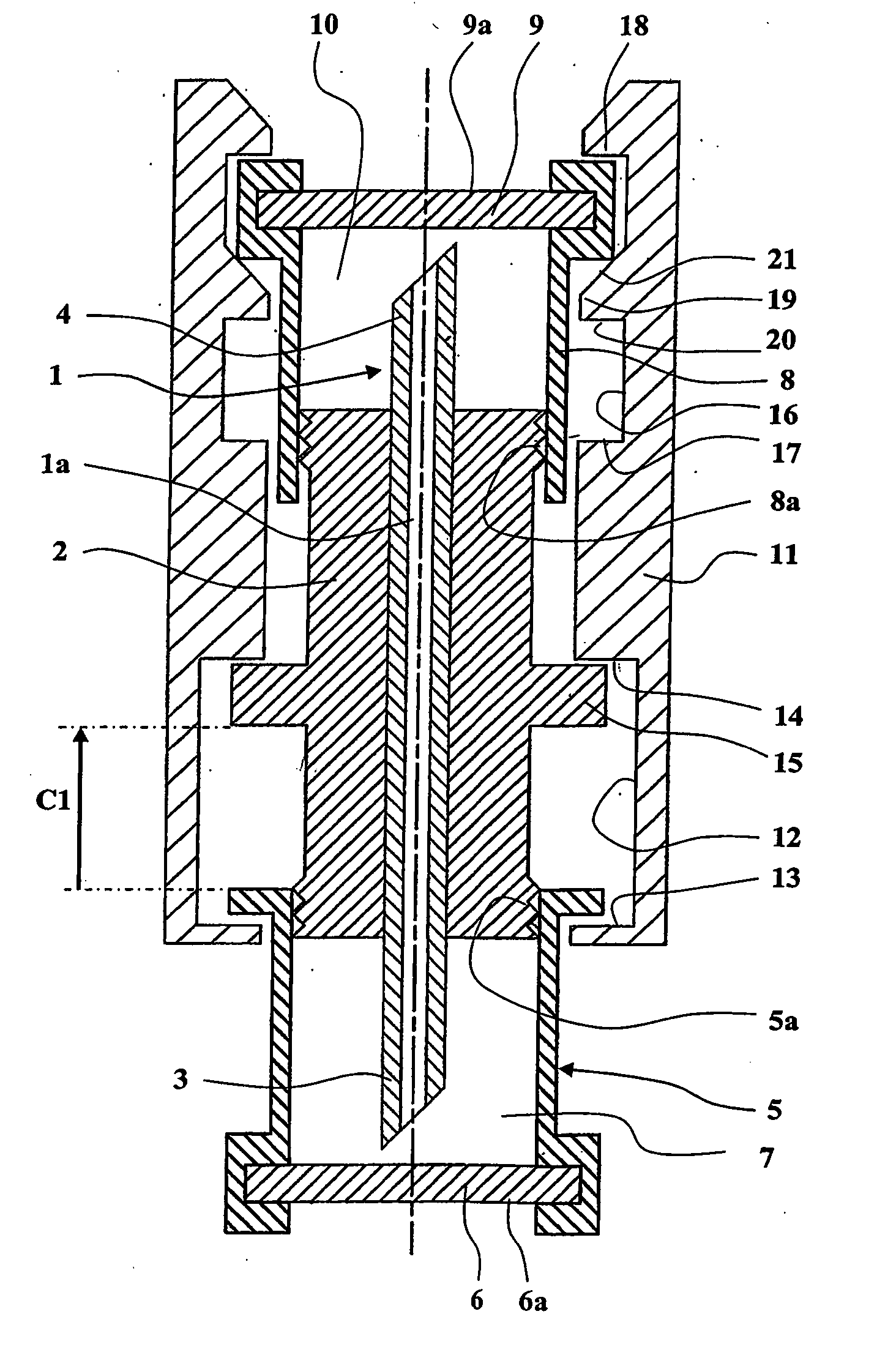

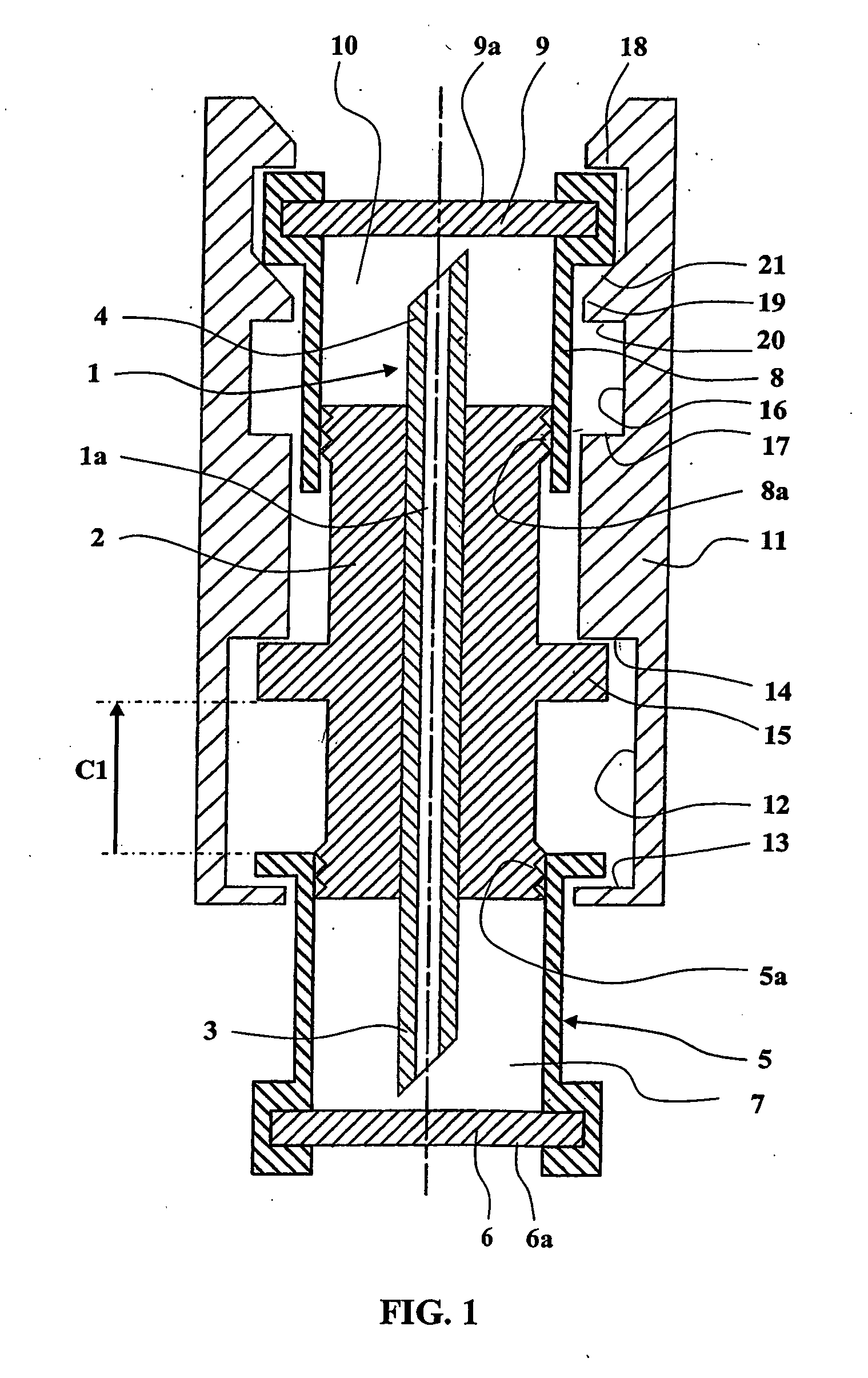

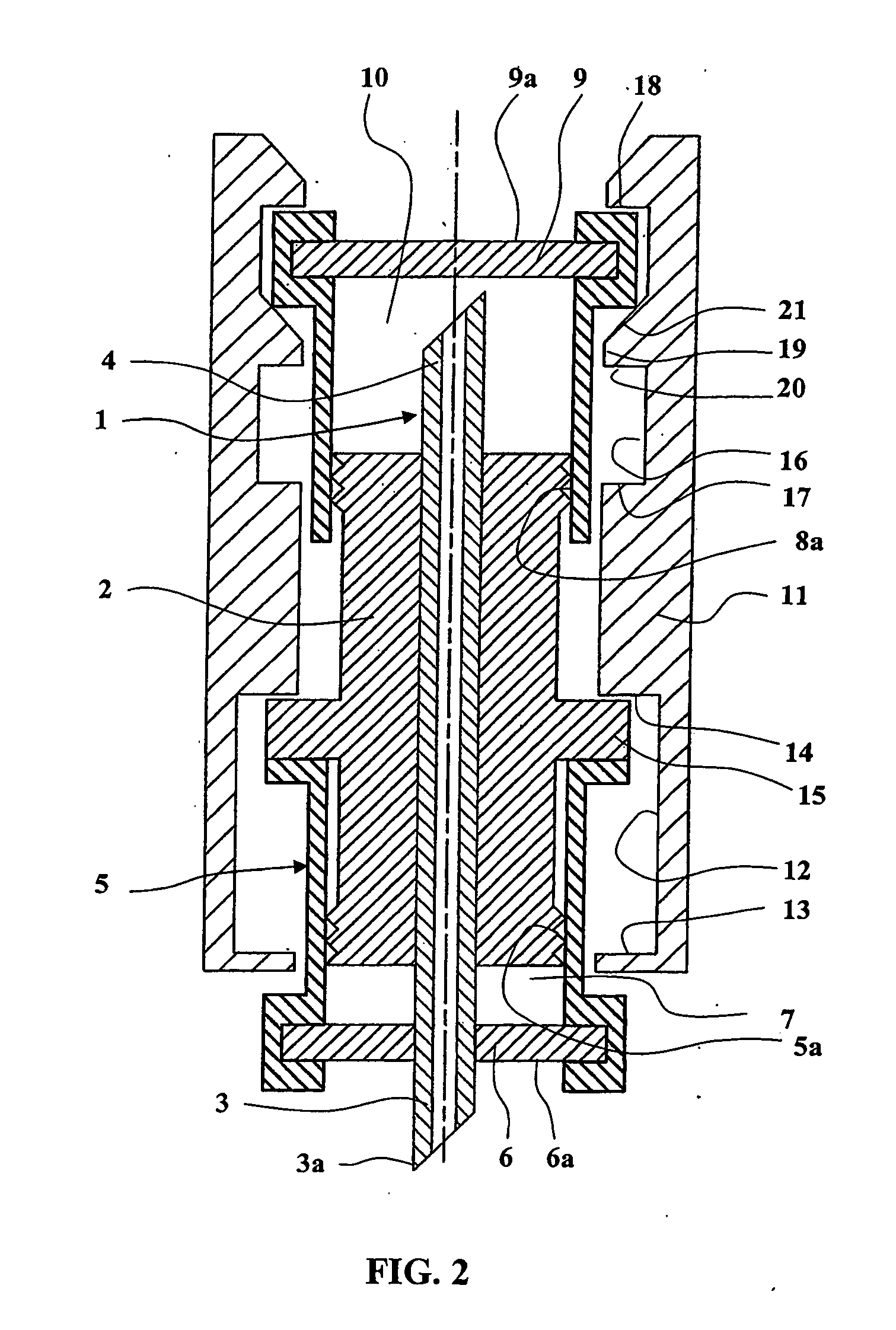

[0031] The embodiment of a perforating connector of the invention shown in the figures comprises a hollow needle 1 with an axial fluid passage 1a, and a needle support body 2 that surrounds and is fixed in a sealed manner to an intermediate section of the needle 1, and which leaves projecting a first end section 3 and a second end section 4 of the needle 1.

[0032] The first end section 3 of the needle 1 is surrounded by a first tubular receptacle 5 closed by a first foil 6. As a result, in an initial or transport position shown in FIG. 1, the first end section 3 of the needle 1 remains confined in a first cavity 7 delimited by the first foil 6, by the first tubular receptacle 5 and by the body 2.

[0033] Similarly, a second tubular receptacle 8 surrounds the second end section 4 of the needle 1 and is closed by a second foil 9. As a result, in an initial or transport position shown in FIG. 1, the second end section 4 of the needle 1 is confined in a second cavity 10 delimited by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com