Electric drive mower with trailed auxiliary power source

a technology of electric drive and mower, which is applied in the direction of battery/fuel cell control arrangement, vehicle maintenance, propulsion by batteries/cells, etc., can solve the problems of significant damage to golf greens or fairways, difficult and impractical to mow large areas, and the range of battery packs carried by the present mower remains inherently limited by the power capabilities of conventional batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

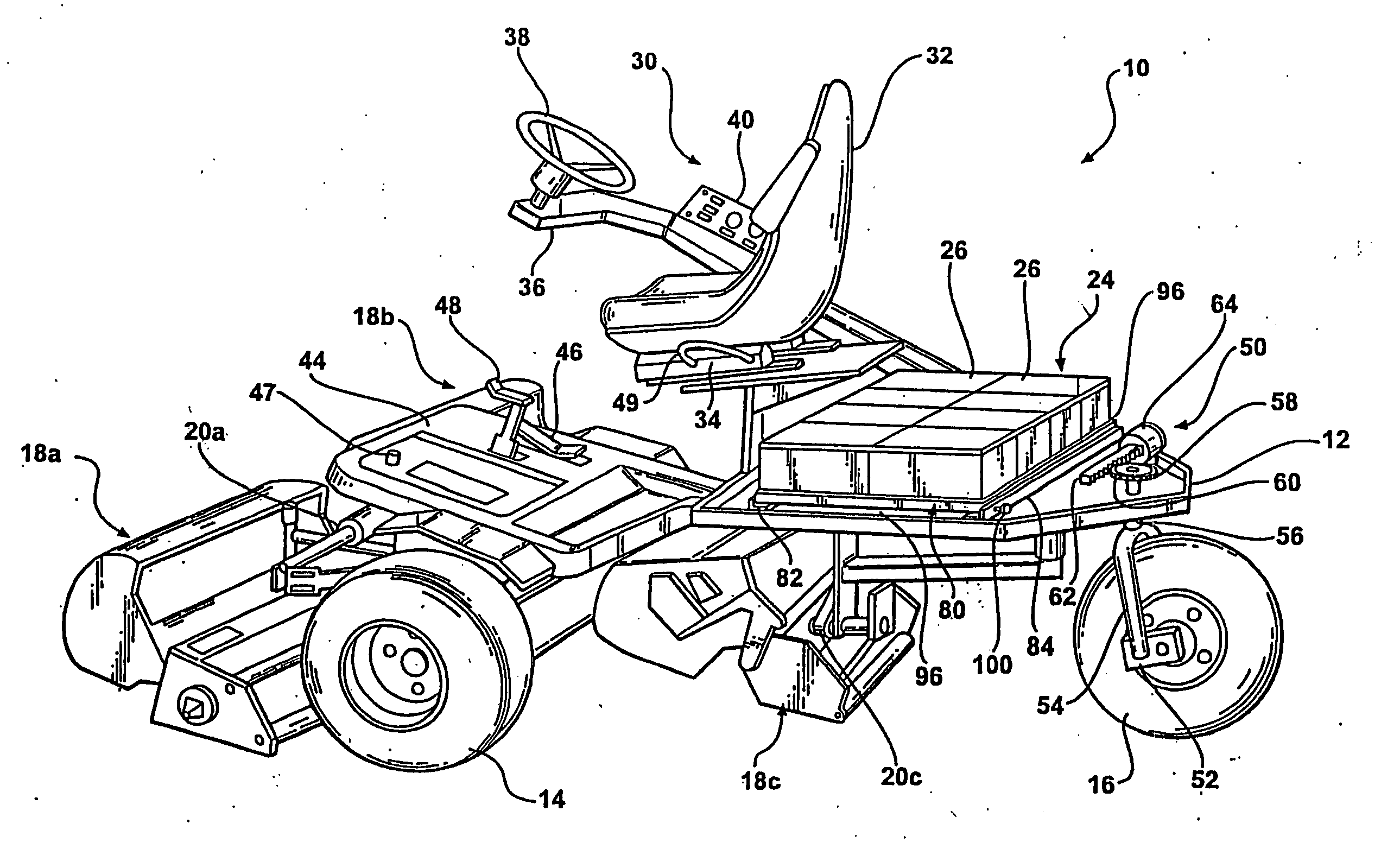

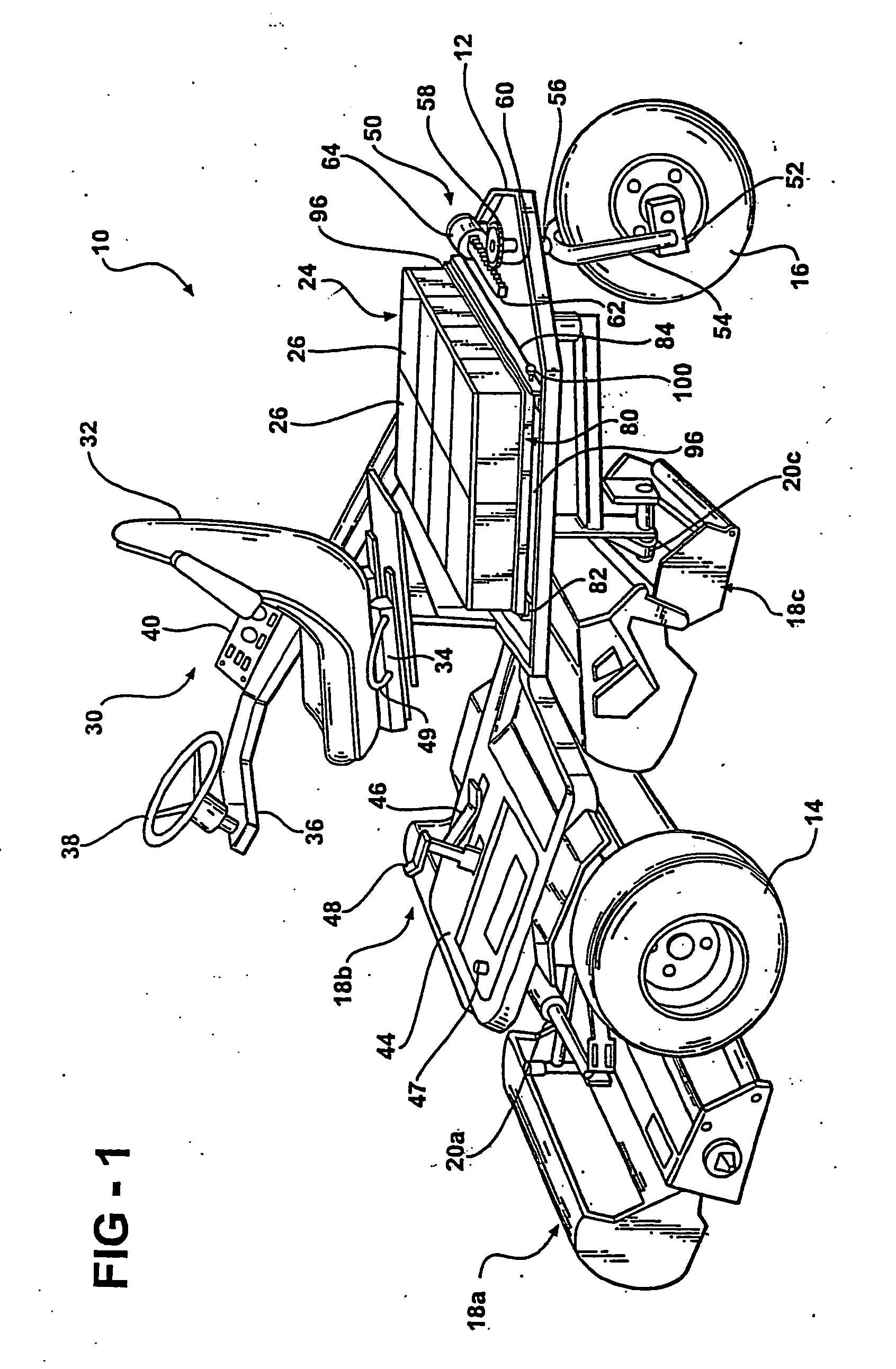

[0045]FIGS. 1 and 3 depict the present invention in which the power source 24 engages a guided, rolling platform to facilitate the interchange of power sources 24. Referring to FIGS. 1 and 3, a roller tray assembly 80 is mounted to the frame 12 of the mower 10. The roller tray assembly includes an angled channel 82 mounted forward of the power source 24 so that the power source 24 is seated within the angular portion of the angled channel 82. The angled channel 82 provides a forward retainer and guide for the power source 24. A second angled channel 84 is mounted rearward of the power source 24 so that the power source is seated within the angled portion of the angled channel 84. The angled channel 84 both guides and retains the power source 24, and in particular, provides a rear retainer for the power source 24. A plurality of rollers 86 connect the angled channels 82 and 84 to facilitate the interchange of the power source 24. The rollers 86 include substantially rigid rods 88 ext...

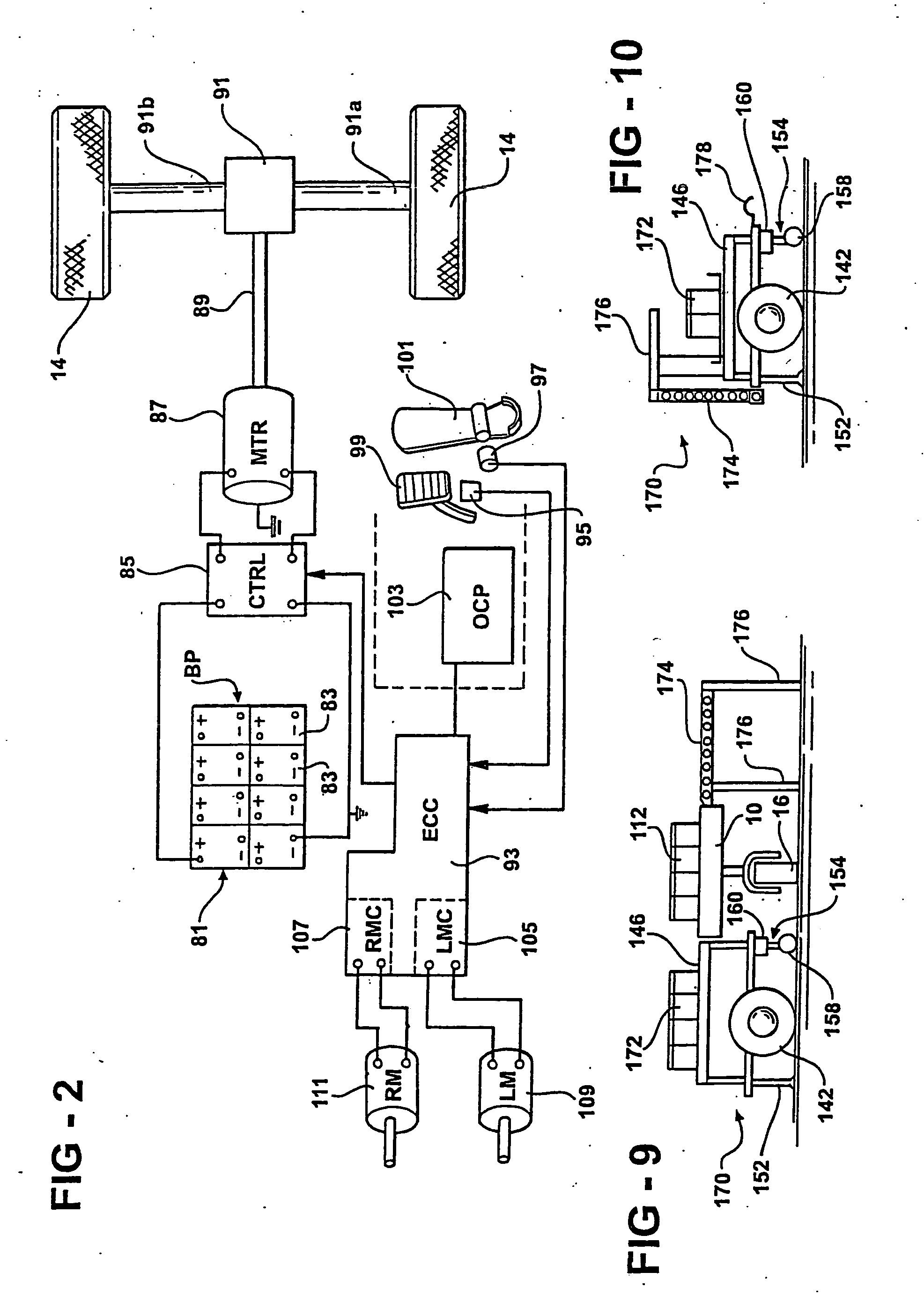

second embodiment

[0053] In a trailer adapted for direct interchange, FIGS. 9 and 10 depict a trailer 170 for direct exchange of a discharged power source 112 with a charged power source 172. Note that like reference numerals from FIGS. 7 and 8 will be used to reference similar elements in FIGS. 9 and 10. FIG. 9 depicts a rear view of the mower 10 with the trailer 170 arranged to the left side of the mower and supporting a charged power source 172 for replacing the discharged power source 112. In operation, a temporary stand 174 is erected on a side of the mower 10 opposite the trailer 170. Temporary stand 174 includes a pair of legs 176 which support the combined weight of the stand 174 and the power source disposed thereon. The discharged power source 112 is removed from the mower 10 by sliding it toward the right of the mower onto temporary stand 174. Once discharged power source 112 has been positioned on temporary stand 174, charged power source 172 may then be moved from the trailer 170 onto th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com