Determination of thin film topograhpy

a thin film topography and topography technology, applied in the direction of measuring devices, instruments, using optical means, etc., can solve the problem that current thin film measurement methods do not possess such a universal appeal, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Interferometric techniques play an important role in the measurement of thin transparent films on substrates. The simplest interferometric method of measuring the thickness hfilm,(x,y) of a non-uniform thin film involves creating an image by superposition of beams reflected from two interfaces: air / film and film / substrate.

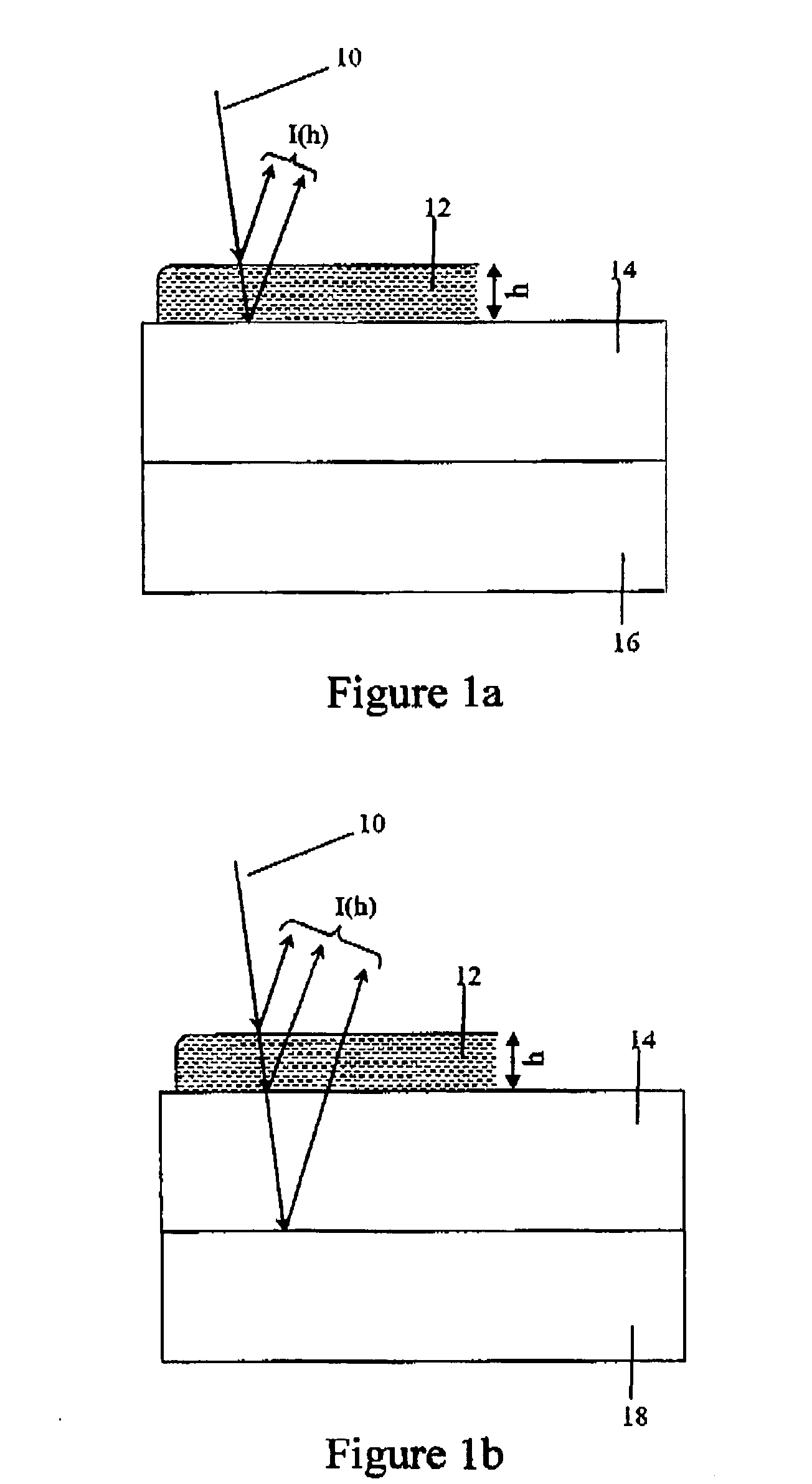

[0053]FIG. 1a illustrates two-beam interferometry for measuring the thickness of a thin water film 12 over a mica substrate 14. Incident light beam 10, which is either coherent or partially coherent with coherence length that is at least equal to the maximum thickness of the film (hereinafter—partially coherent), is directed onto thin film 12, and is partially reflected and partially refracted through. The refracted portion of the beam traverses through the thin film and then reflected by the water-mica interface. Absorbing grease 16 laid beneath mica substrate 14 is provided to inhibit reflections off the back surface of the mica substrate 14.

[0054] This ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com