Phosphorescent phosphor powder, manufacturing method thereof and afterglow fluorescent lamp

a technology of fluorescent lamps and phosphorescent phosphor powder, which is applied in the direction of discharge tubes/lamp details, discharge tubes luminescnet screens, gas-filled discharge tubes, etc., and can solve the problem of lowering the light emission intensity of lamps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

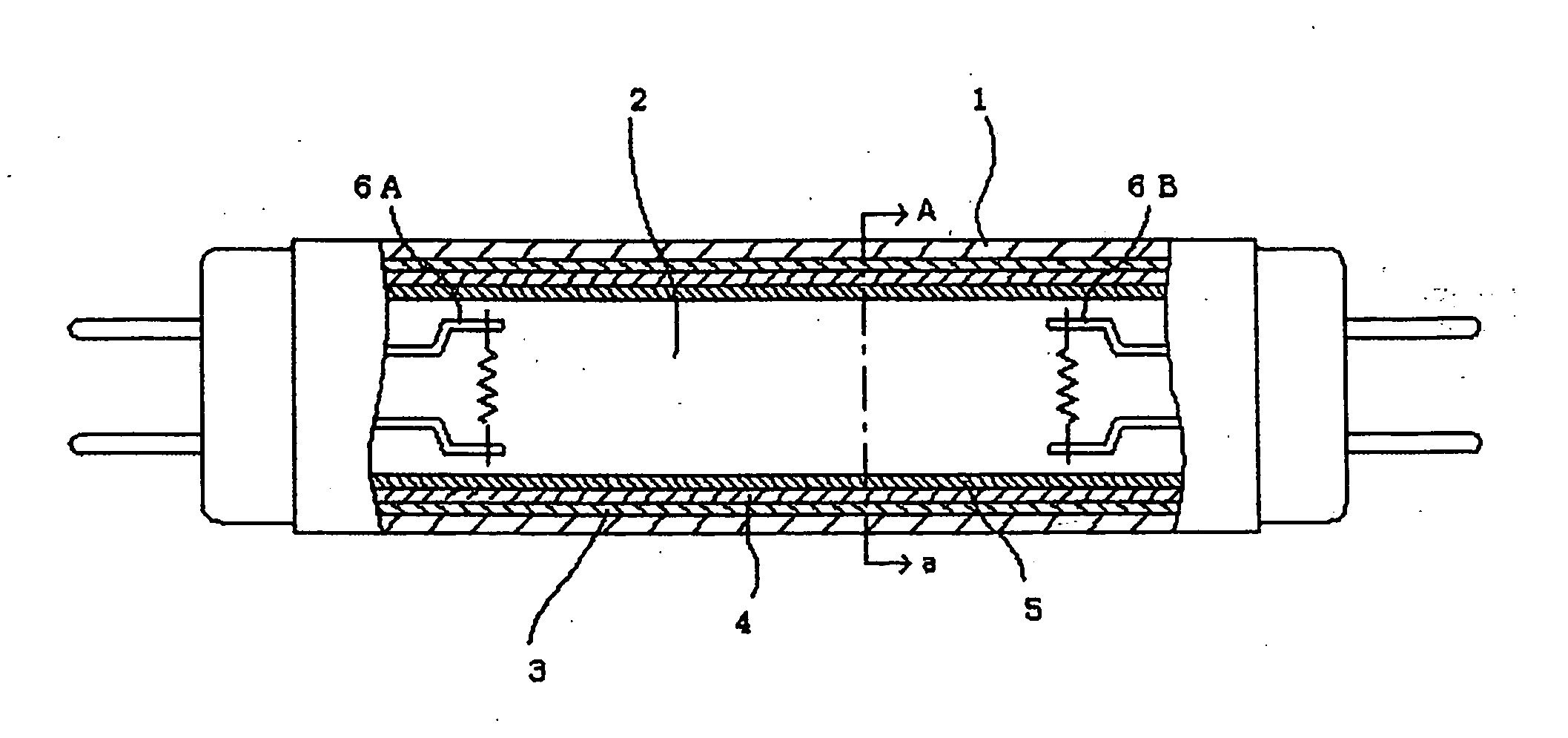

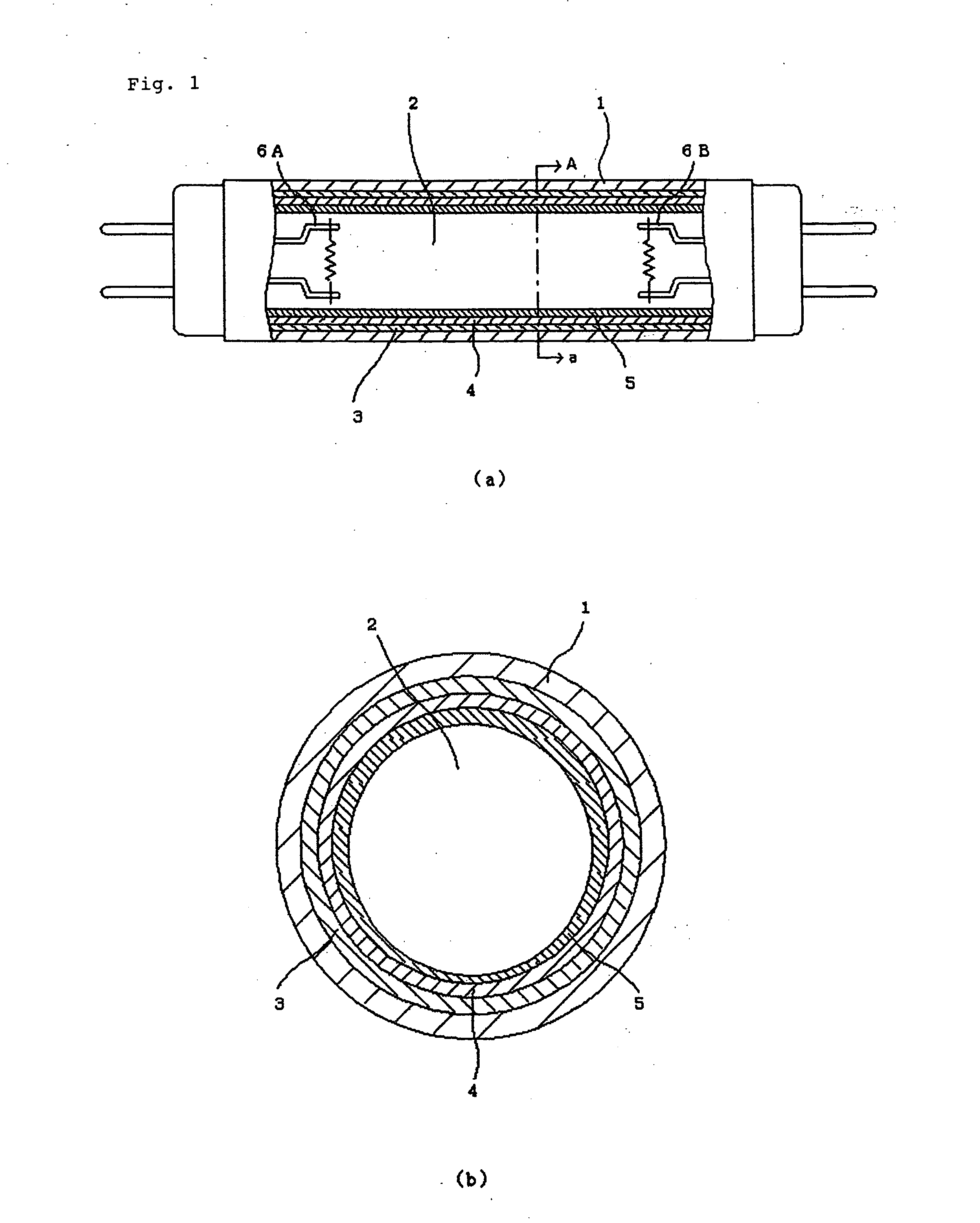

[0027] For a phosphorescent phosphor layer 4, there was used a layer in which α-alumina particles with a size distribution of 0.3 μm to 5 μm were mixed with phosphor particles of SrAl2O3: Eu, Dy having an average particle size of 10 μm and a particle-size distribution of 5 μm to 20 μm. As for the content of the α-alumina particles in the phosphorescent phosphor layer, three levels of the content ratio by weight, 10 wt %, 20 wt % and 40 wt % were chosen to use.

example 2

[0038] Afterglow fluorescent lamps each with the same structure as Example 1 were fabricated, using the same manufacturing method as Example 1 except that γ-alumina particles, instead of α-alumina particles, were contained in the phosphorescent phosphor layer 4.

[0039] The same test as performed in Example 1 was conducted for the fabricated lamps, and the same results as shown in Table 1 were obtained. Further, the effects of suppressing the sanding phenomenon were also obtained as Example 1.

example 3

[0040] Afterglow fluorescent lamps with the same structure as Example 1 were fabricated, using the same manufacturing method as Example 1 except that a mixed powder of α-alumina particles and γ-alumina particles, which were used in Example 1 and Example 2, respectively, were contained in the phosphorescent phosphor layer 4.

[0041] The same test as performed in Example 1 was conducted for the fabricated lamps, and the same results as shown in Table 1 were obtained. No difference in effects between lamps with different content ratios of α-alumina and γ-alumina was found. Further, the effects of suppressing the sanding phenomenon were also obtained as Example 1.

[0042] The reason why, in Examples 1 to 3, the addition of α-alumina particles, γ-alumina particles or a mixed powder of α-alumina particles and γ-alumina particles in the phosphorescent phosphor layer 4 suppressed the pinhole appearance is thought as follows.

[0043] As described above, mercury exists in liquid phase when the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com