Control method for controlling the gas flow in a compressor

a compressor and gas flow technology, applied in the direction of positive displacement liquid engines, piston pumps, liquid fuel engines, etc., can solve the problems of large wear, slow closure/opening of gas flow, and large energy consumption, and achieve the effect of large wear and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

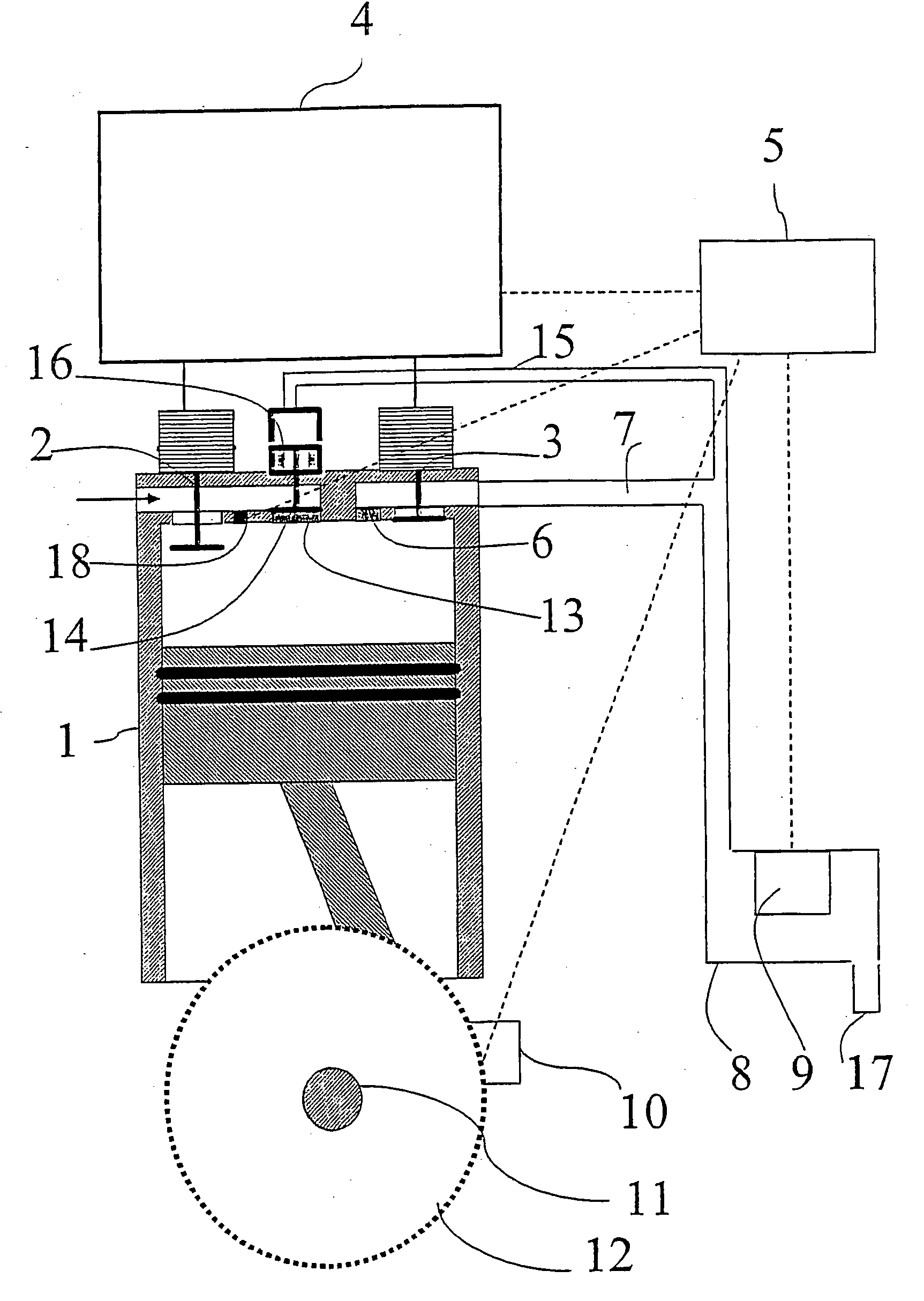

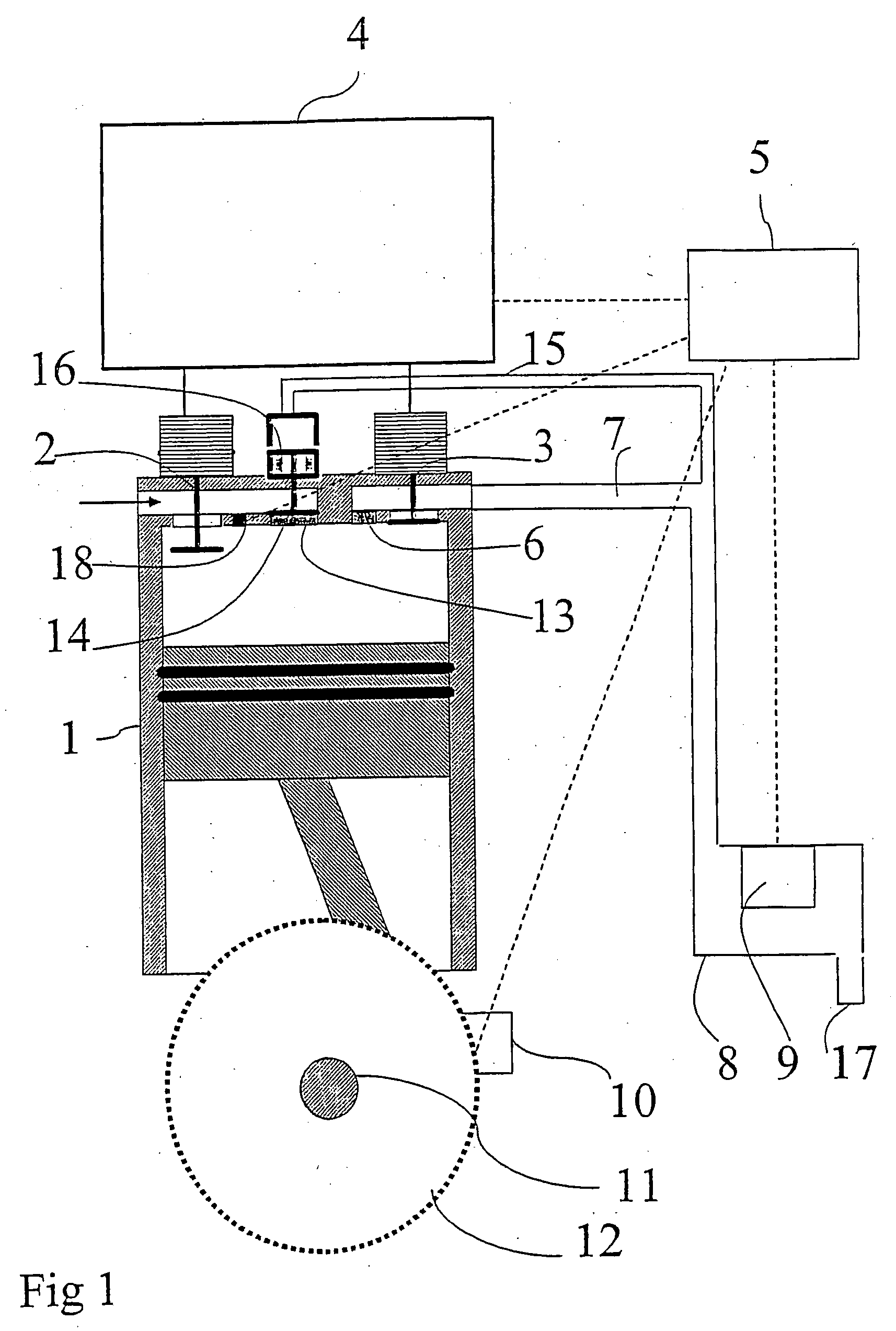

[0027]FIG. 1 is an exemplifying, schematic picture that shows a compressor cylinder with a-piston 1. The piston is under movement during an intake stroke, and air (or any other gas) is flowing through the open inlet valve 2. The inlet valve 2 and the closed outlet valve 3 are constituted by controllable valves that are pneumatically, hydraulically or electromagnetically operable. A circuit 4 is used for operating the valves 2 and 3. A control unit 5 is operatively connected with the circuit 4 for signal control of the circuit and the valves 2 and 3 that are connected to the circuit. Air that is compressed is transported through the outlet valve 3 and / or a non return valve for the outflow of gas 6 through a conduit 7 to a tank 8. By means of a sensor 9 in the tank 8, which is operatively connected to the control unit 5, the control unit is provided with continuous information about the pressure in the tank. A sensor 10, arranged at a graduated arc 12, mounted on the compressor shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com