Method and apparatus for measuring accumulated and instant rate of material loss or material gain

a technology of instant rate and material loss, applied in the direction of measuring devices, electric/magnetic thickness measurements, instruments, etc., can solve the problems of insufficient resolution of these techniques, inaccurate or misleading, and none of the techniques provide a fast measurement of instant rate of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

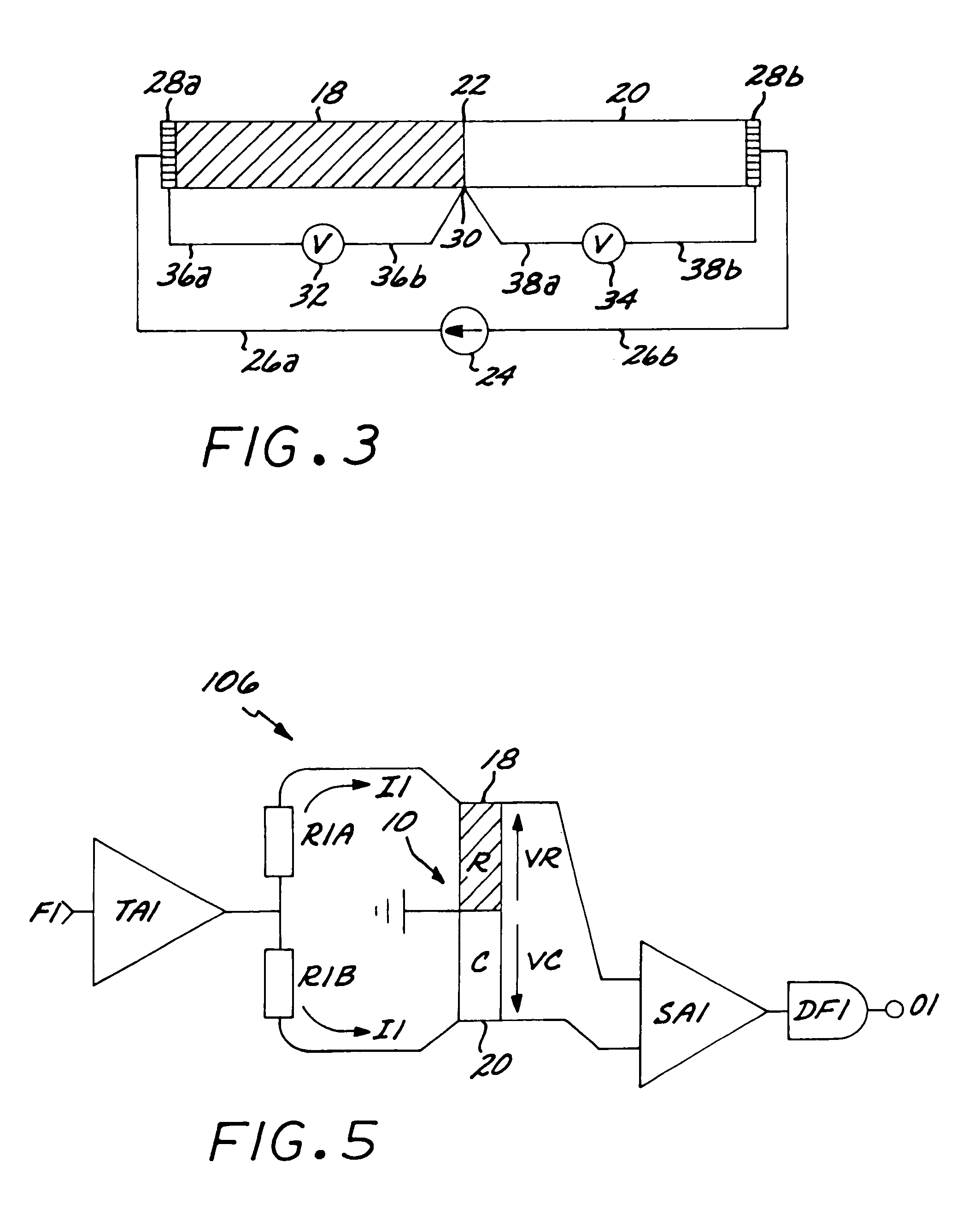

[0104] The implementation of the invention as described above will be described below with reference to FIGS. 5 to 9, including several alternative embodiments, which additionally may be implemented in numerous ways. The invention may be implemented in accordance with a first embodiment, comprising a bridge circuitry designated in its entirety by numeral 106 and shown as a circuit diagram in FIG. 5 having a power transmitter amplifier TA1 being supplied with an AC input signal at frequency F1.

[0105] The power transmitter amplifier TA1 provides a current excitation output, which is split into two equal excitation currents I1 in to two lines. The first line is connected to the coated first section 18 of the metal element 10 via a resistor R1A. The second line is connected to the non-coated second section 20 of the metal element 10 via a resistor R1B. The resistors R1A and R1B provide similar electrical resistance, which resistance is substantially larger than the electrical resistance...

second embodiment

[0112] the invention in accordance with FIG. 6 further comprises a second power transmitter amplifier TA2 being supplied with a second alternating input signal at a second frequency F2.

[0113] The second power transmitter amplifier TA2 provides a second current excitation output having the second frequency F2, which current excitation output is split into two equal excitation currents I2 in to two lines. The second excitation current I2 is fed to the coated first section 18 and the non-coated second section 20 of the metal element 10 via resistors R2A and R2B, which resistors R2A and R2B are of the same order of magnitude as resistors R1A and R1B.

[0114] The first and the second input signals are fed to the first and second power transmitter amplifier TA1 and TA2 respectively through the input circuit 110 constituted by two the potentiometers P1 and P2. The potentiometers P1 and P2 provide two alternating voltage input signals to the first and second power transmitter amplifier TA1 a...

third embodiment

[0153]FIG. 9 shows a circuit diagram of a complete circuit 118 constituting the invention. The complete circuit 118 comprises all the features described with reference to FIGS. 1 through 8.

[0154] A first crystal designated by XO1 in FIG. 9 provides a first square-wave signal to a first four-quadrant phase splitter FS1. The first four-quadrant phase splitter FS1 provides square-wave signals in four phases at 0°, 90° 180° and 270° at a first frequency F1, i.e. shifted by a 90°-phase delay from each other.

[0155] Similarly a second crystal designated by XO2 provides a second square-wave signal to a second phase splitter FS2 providing four phase-signals at a second frequency F2, i.e., at 0°, 90°, 180° and 270° phases. These signals are used as phase reference inputs for five synchronous detectors DF1R, DF1I, DF2CR, DF2CI and DF2RR and as signal inputs for balance potentiometers I-BAL and R-BAL, power transmitter amplifiers TA1, TA2, TA3 and TA4 and first and second digital ladders LD1 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| resistances | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| voltages | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com