Wipes dispenser with a wide-mouthed dispensing aperture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

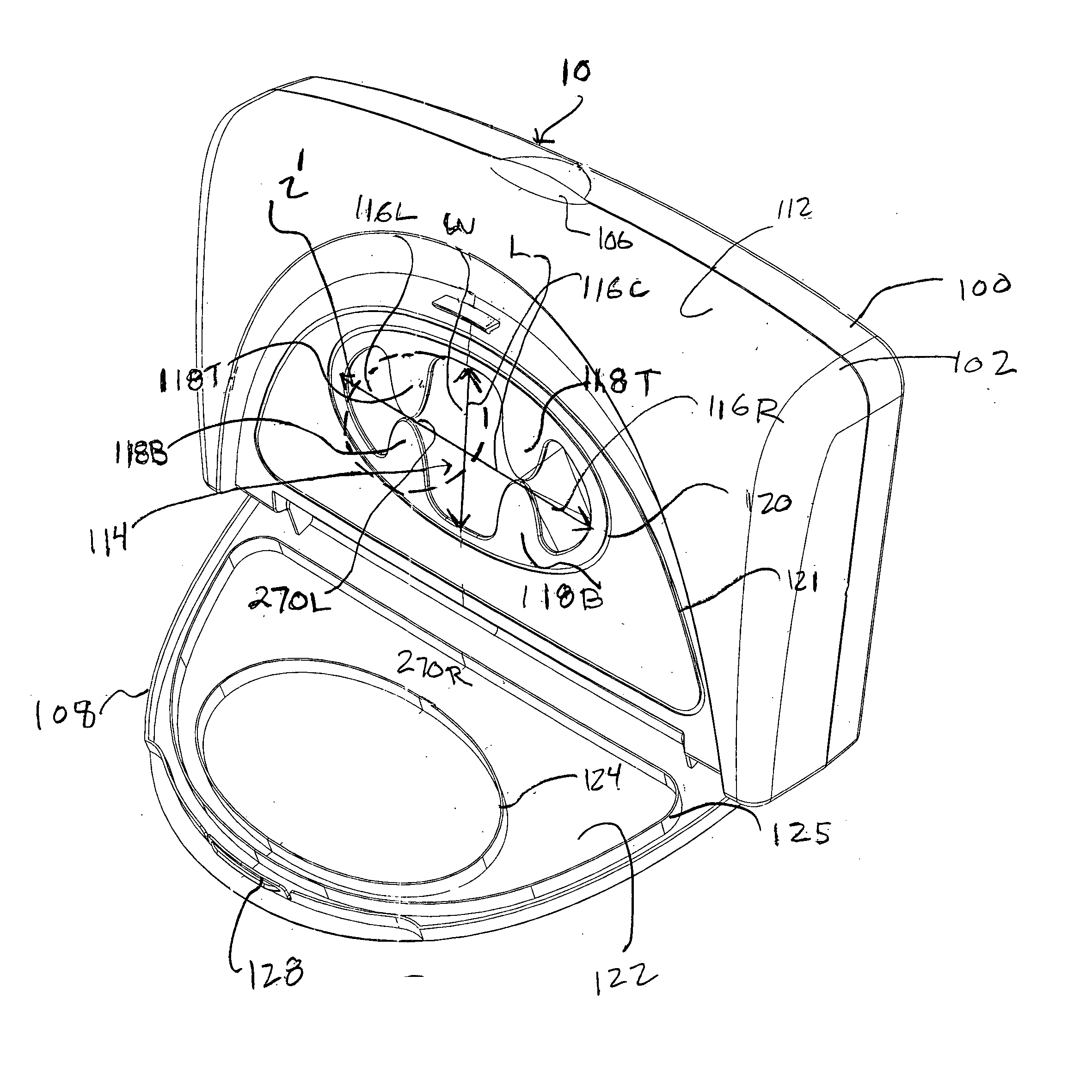

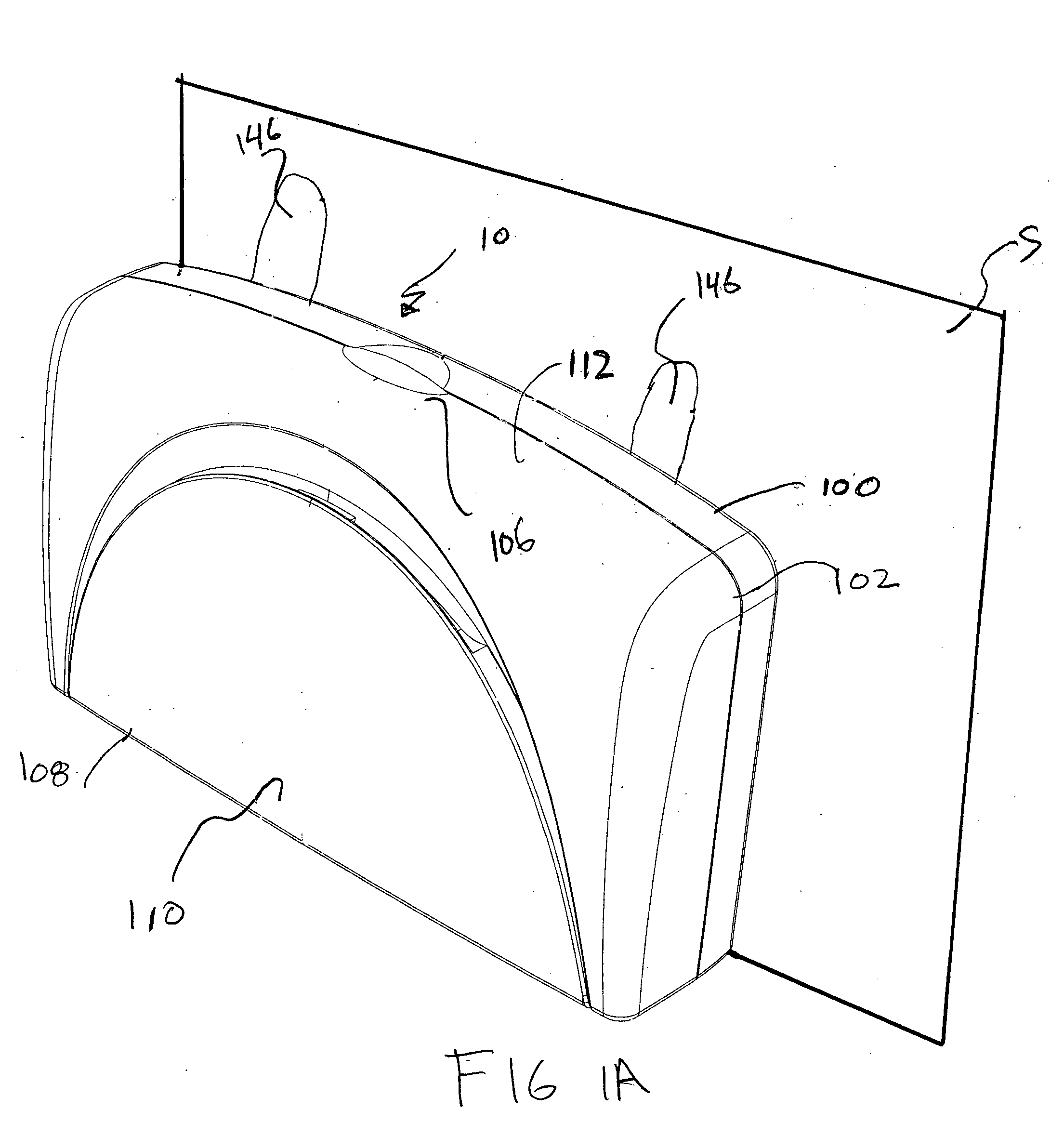

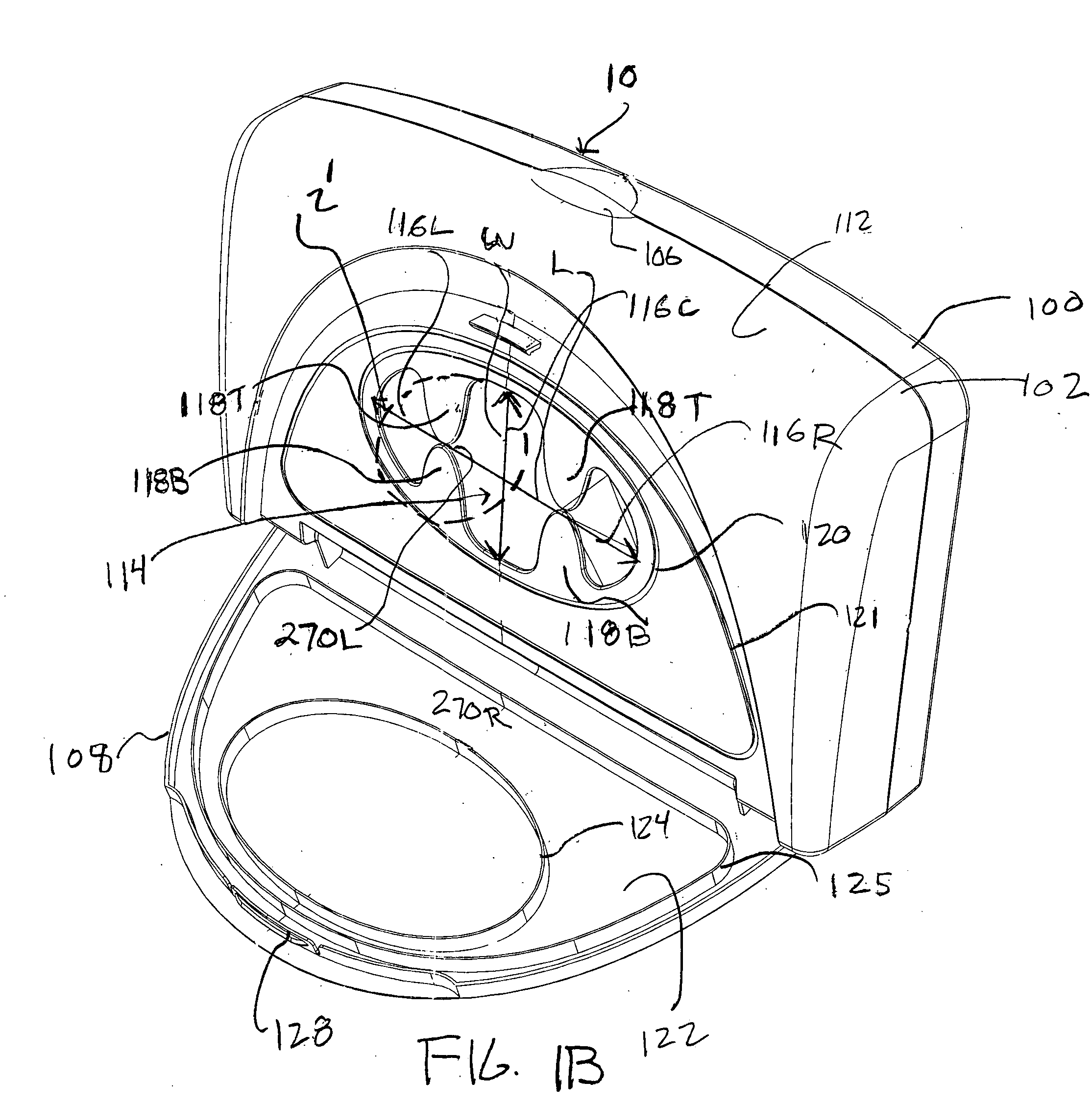

[0035] In accordance with the principles of the present invention, in one embodiment, provided is a wipes dispenser having a wide-mouthed wipes dispensing aperture configuration. The wipes dispenser provides for convenient and easy dispensing of wipes in a variety of environments and in various orientations of the wipes dispenser.

[0036] In one embodiment, the wipes dispenser of the present invention includes a base and a refill door pivotably or releasably coupled to the base. When the refill door is placed in a closed position relative to the base, a pouch space is defined by the inside surfaces of the base and the refill door.

[0037] In one embodiment, a wipes dispenser of the present invention further includes a replaceable pouch, which contains a stack of singulated, folded, interleaved wipes or a laterally perforated web of wipes. In use, the refill door of the dispenser is placed in an open position relative to the base. The pouch is placed between the base and the refill doo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com