Bill separator using frictional force

a frictional force and separator technology, applied in the field of bill separators, can solve the problems of difficult installation and repair of conventional bill separators, large amount of time consumed, etc., and achieve the effect of convenient installation and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, a bill separator using frictional force according to a preferred embodiment of the present invention will be described in detail with reference to the accompanying drawings.

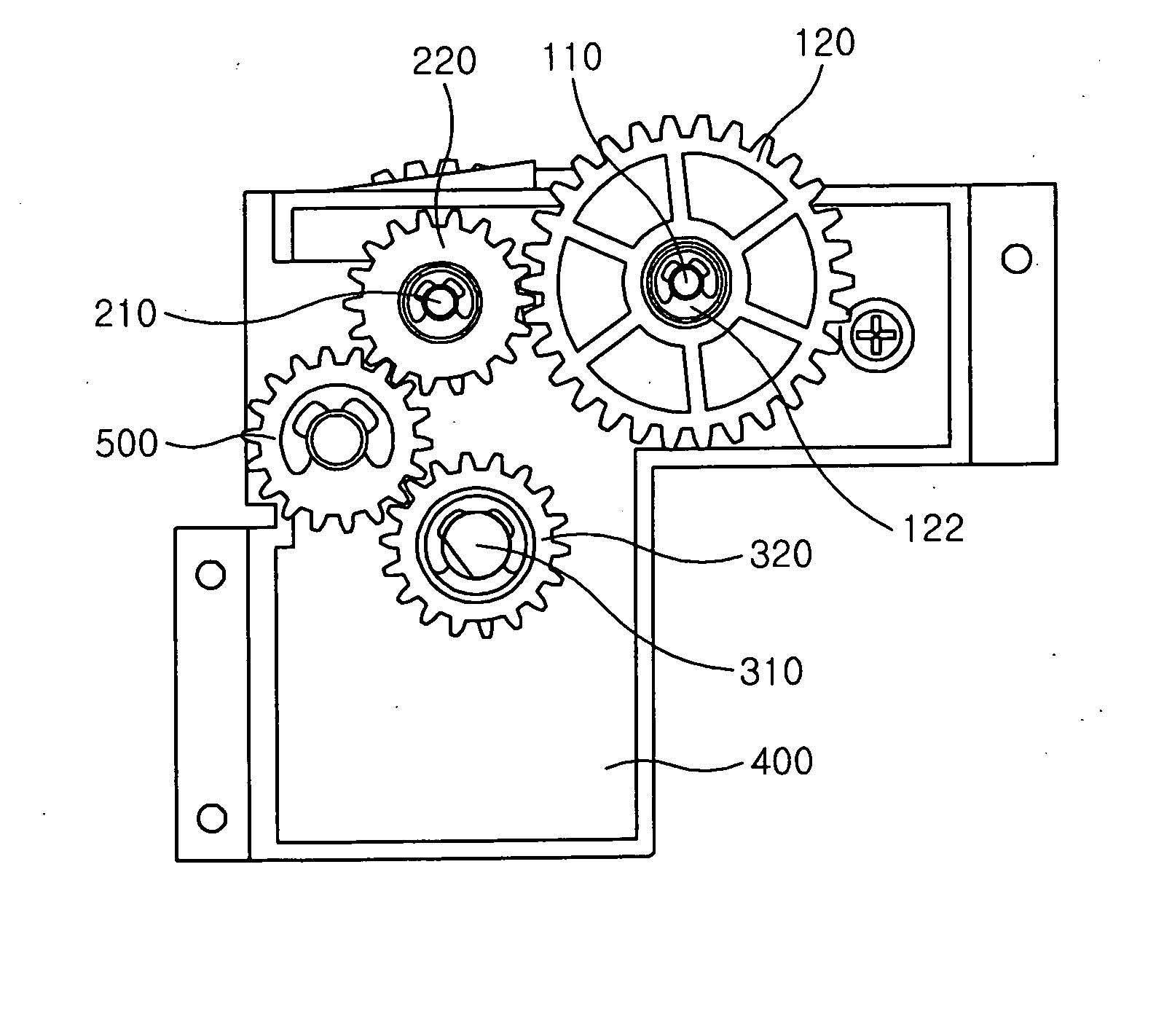

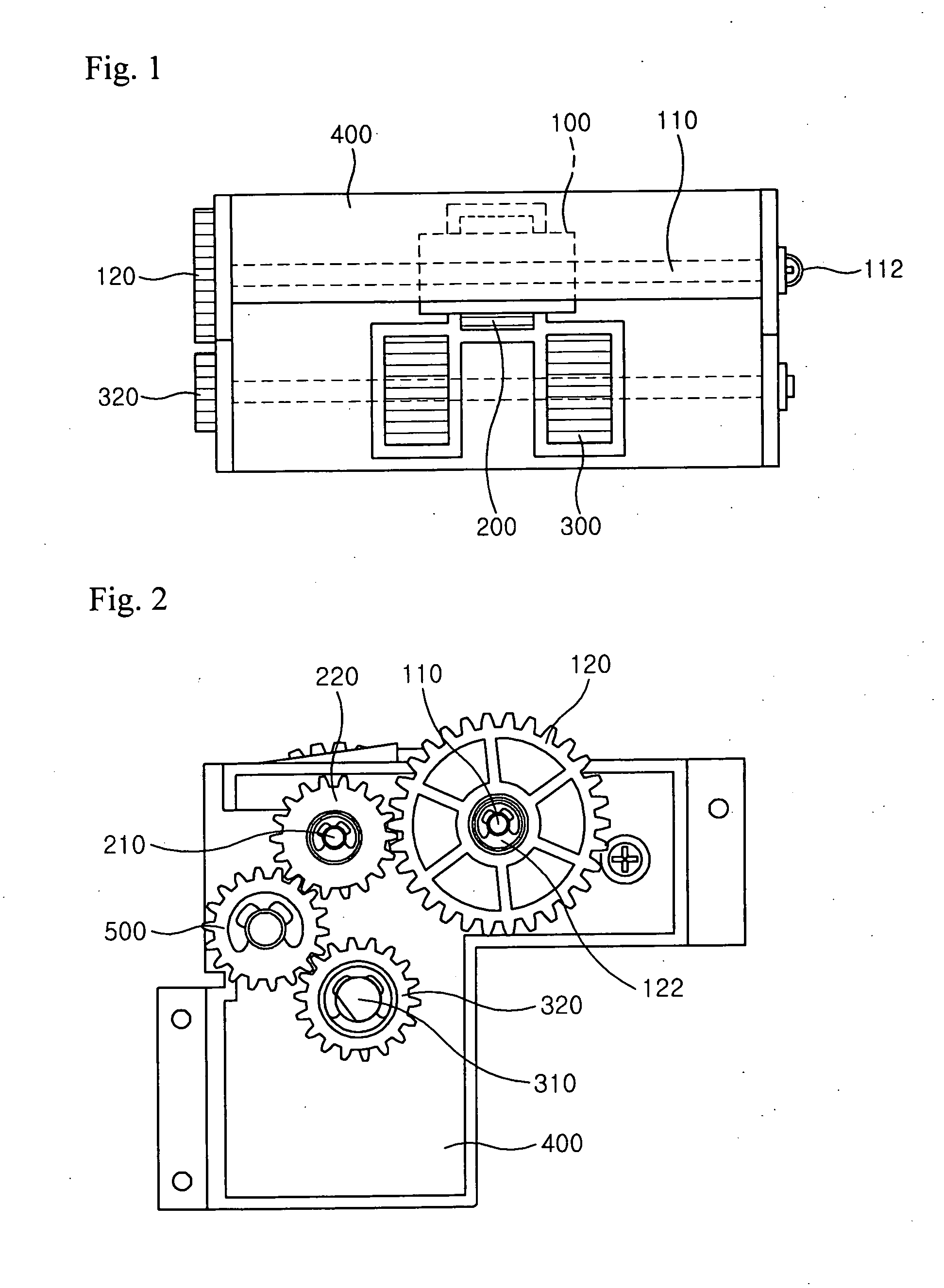

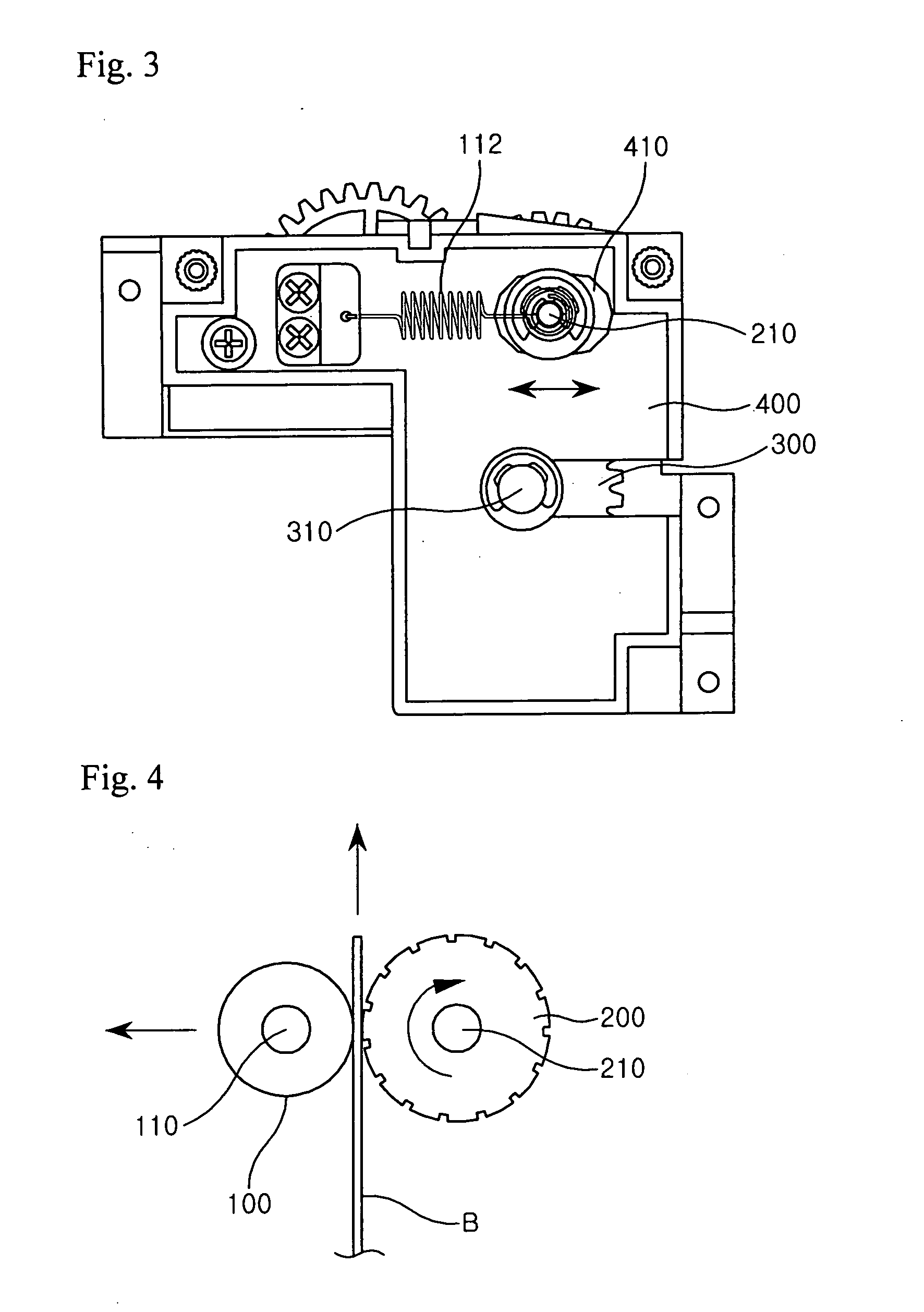

[0019] FIGS. 1 to 3 are a front view, a left side view and a right side view of a bill separator using frictional force according to an embodiment of the present invention, respectively.

[0020] As shown in FIGS. 1 to 3, the bill separator using frictional force according to the present invention comprises a gate roller 100, a feeding roller 200, a pick-up roller 300, and a main body 400. The gate roller 100 is formed of a material with a friction coefficient higher than that of a bill and has a horizontal gate roller rotational shaft 110 coupled thereto along a central axis thereof. The gate roller 100 is constructed such that it cannot rotate in a bill-discharging direction but can rotate in a direction opposite to the bill-discharging direction. The feeding roller 200 is formed of a materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com