Composite insulated panel for upward acting door

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

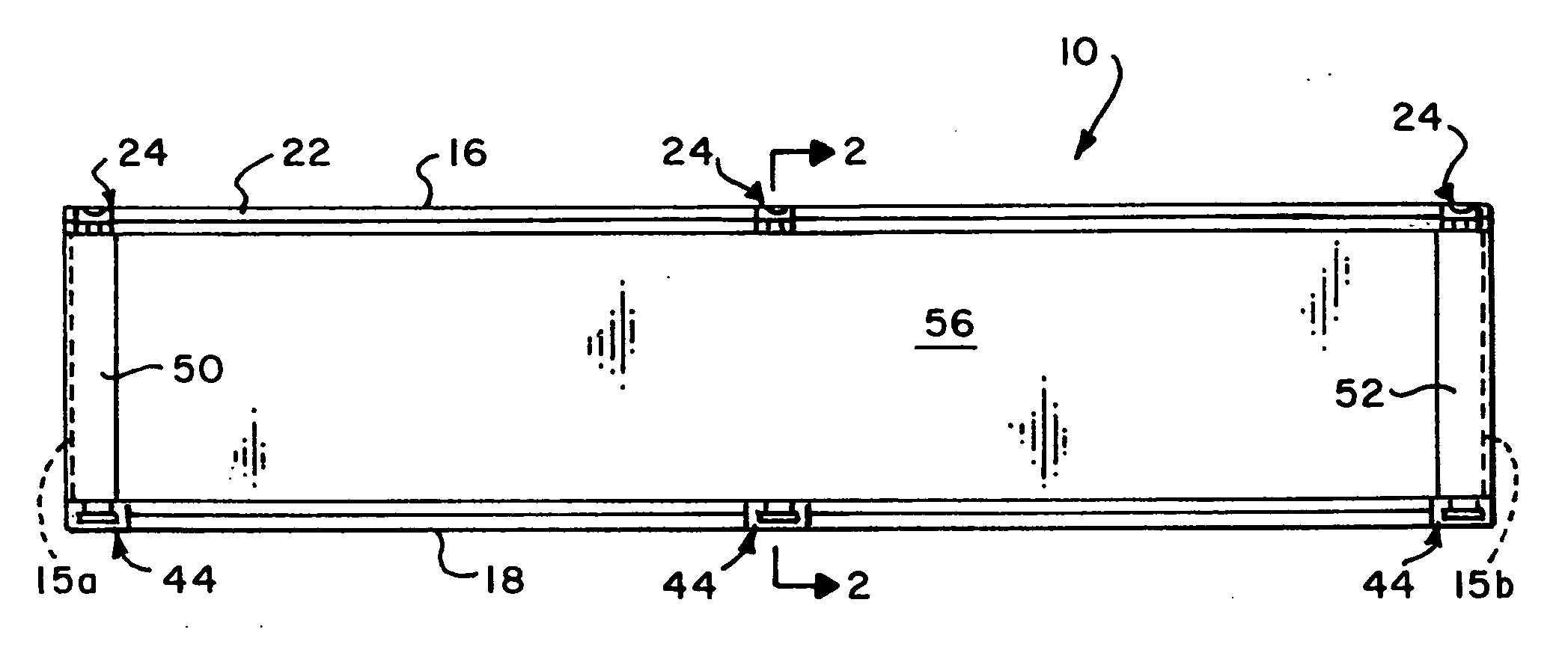

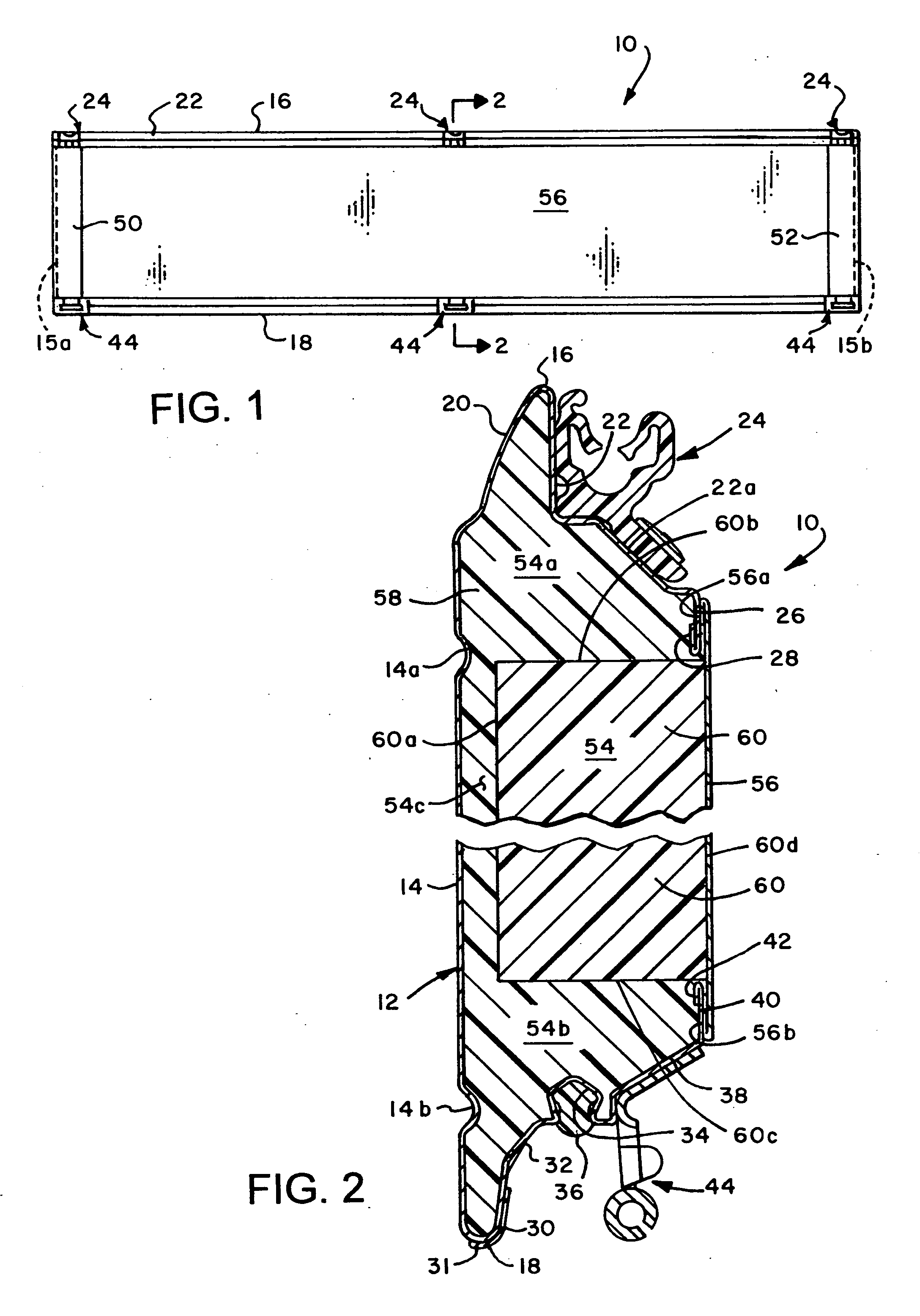

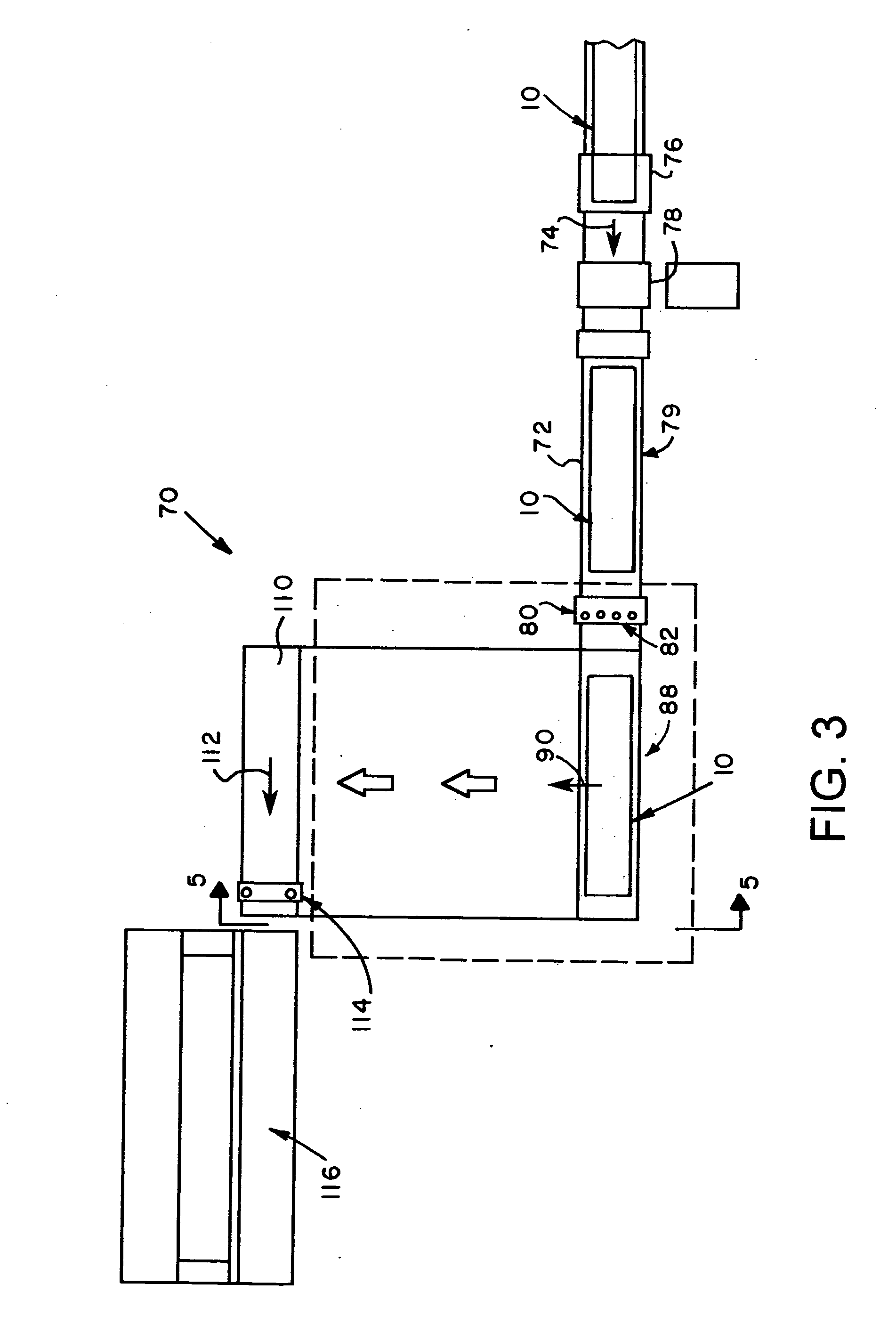

[0014] In the description which follows like parts are marked throughout the specification and drawing with the same reference numerals, respectively. The drawing figures may not necessarily be to scale and certain features may be shown in somewhat generalized or schematic form in the interest of clarity and conciseness.

[0015] Referring to FIGS. 1 and 2, there is shown a sectional door panel in accordance with the invention and generally designated by the numeral 10. The door panel 10 is particularly adapted for being connected to additional door panels to form an upward acting sectional door, such as a residential or commercial garage door or the like. The panel 10 is preferably characterized by a continuous sheet metal member 12 which may be formed by a suitable metal forming process or extruded to provide a front wall 14, an upper edge 16, and a lower edge 18. Alternatively, the panel member 12 may be formed of extruded plastic or formed of more than one part.

[0016] Door panel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com