Power take off

a power take off and assembly technology, applied in the field of power take off assemblies and saws, can solve the problems of large engine and often larger sawing dimensions, less maneuverability, and large sawing, and achieve the effect of small profile, same overall sawing dimension, and higher horsepower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following specification taken in conjunction with the drawings sets forth the preferred embodiments of the present inventions in such a manner that any person skilled in the art can make and use the inventions. The embodiments of the inventions disclosed herein are the best modes contemplated by the inventor for carrying out the inventions in a commercial environment, although it should be understood that various modifications can be accomplished within the parameters of the present inventions.

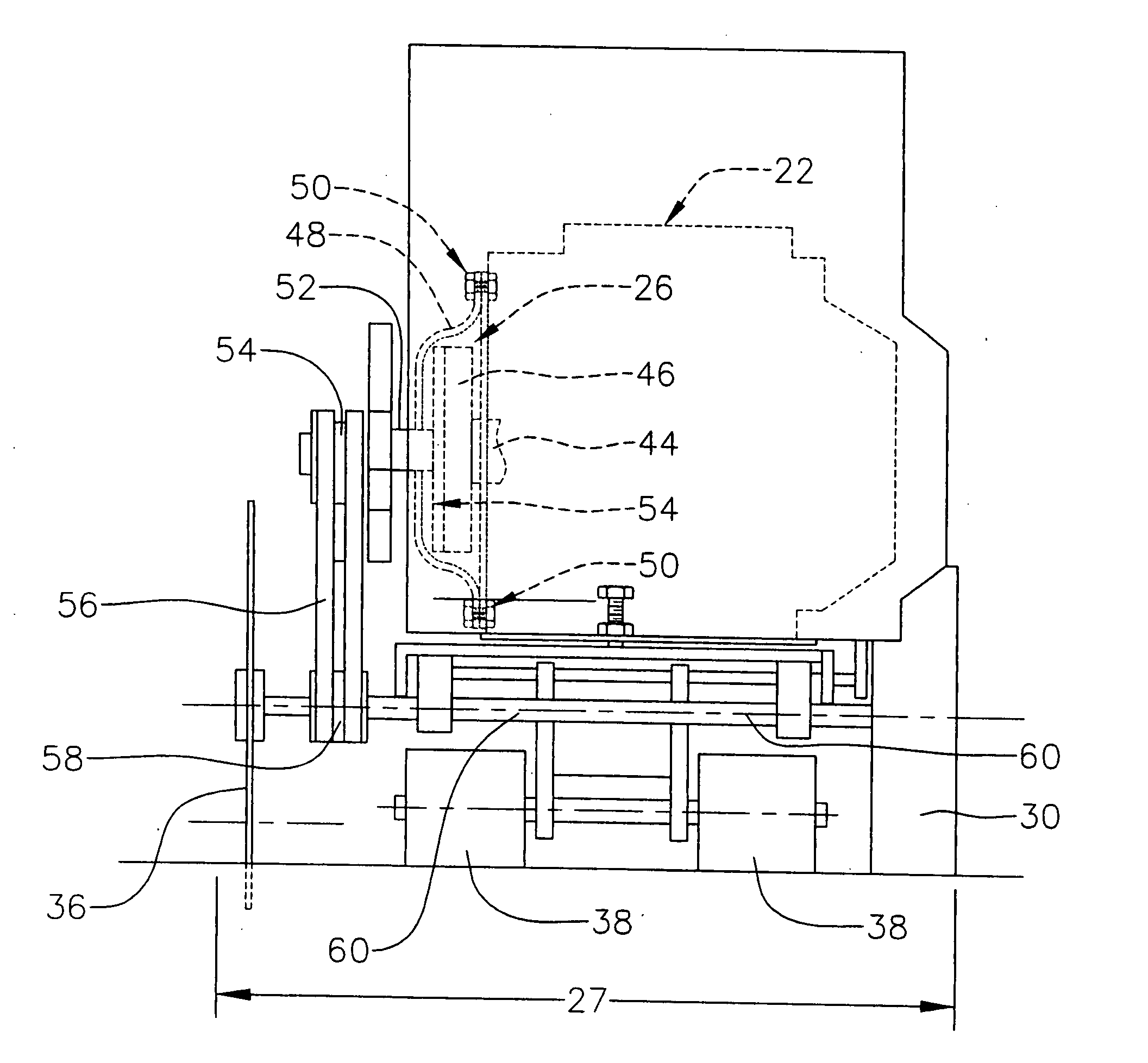

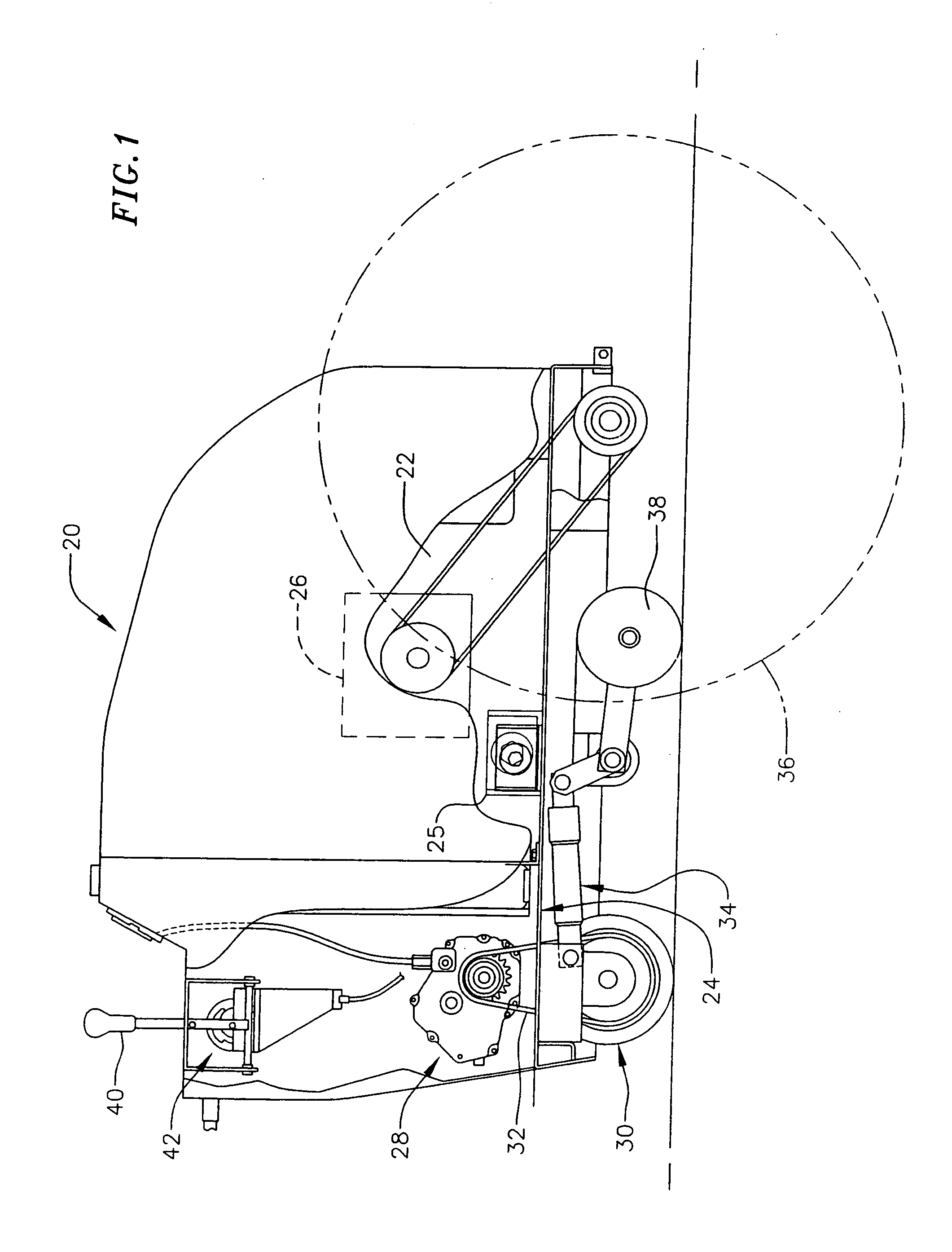

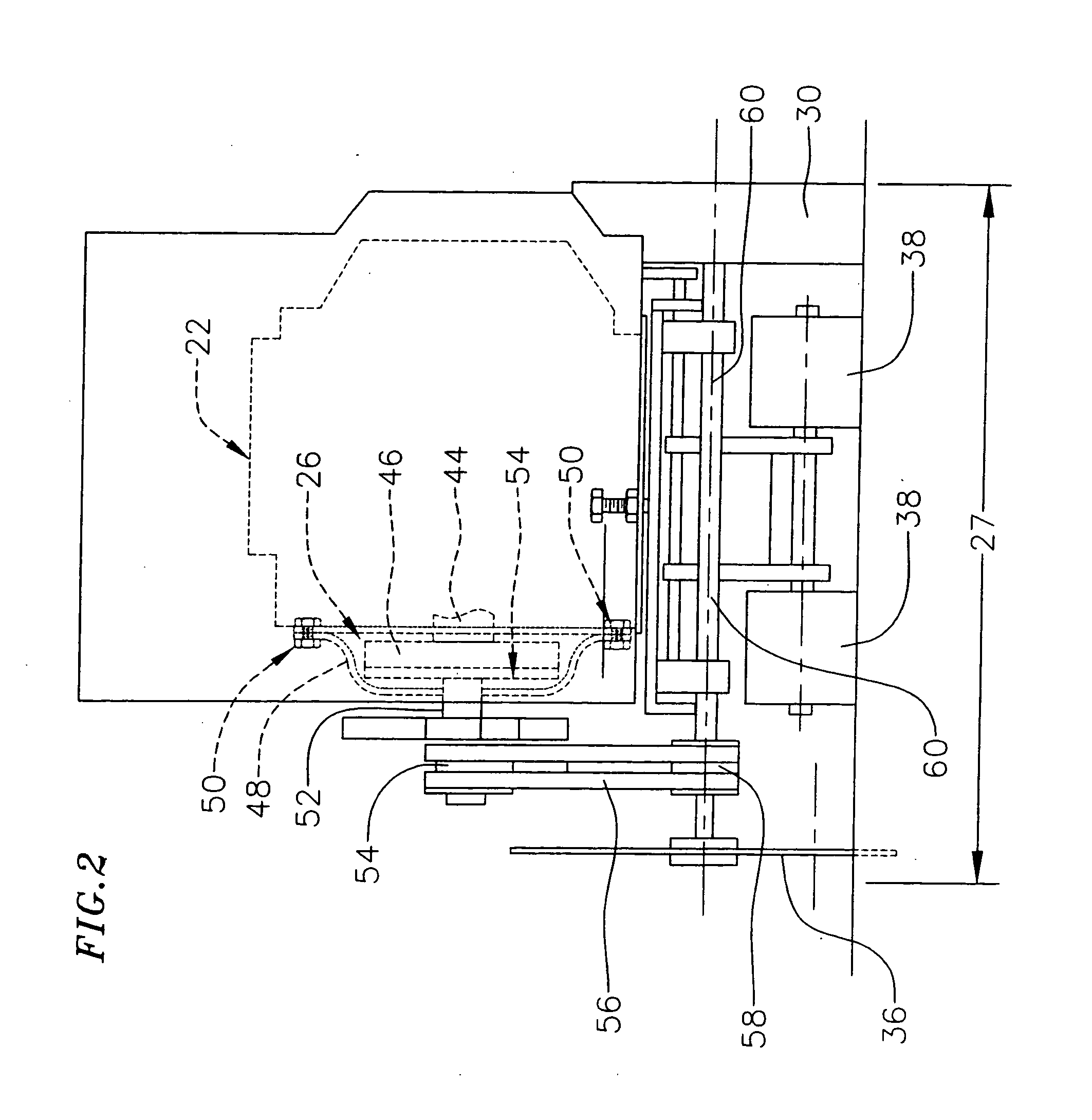

[0033] Mechanical drives and power takeoff assemblies find applications in a number of areas. For the present descriptions, examples of power takeoff assemblies will be given in the context of flat saws or concrete slab saws such as those used to cut pavement, concrete in buildings and other structures, and the like. However, it should be understood that the inventions are not limited to the examples, and can be extended and are applicable to other methods and apparatus as well.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| flexible | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com