Golf club head structure for improving casting fluidity in a slurry shell

a golf club and slurry shell technology, which is applied in the field of golf club head structure for improving casting fluidity in slurry shell, can solve the problems of unsuitable golf club head casting, limited application scope of fe—mn-al alloy in the industry, and difficulty in eliminating contraction cavities by means of finishing grinding process, etc., and achieves the effect of improving casting fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

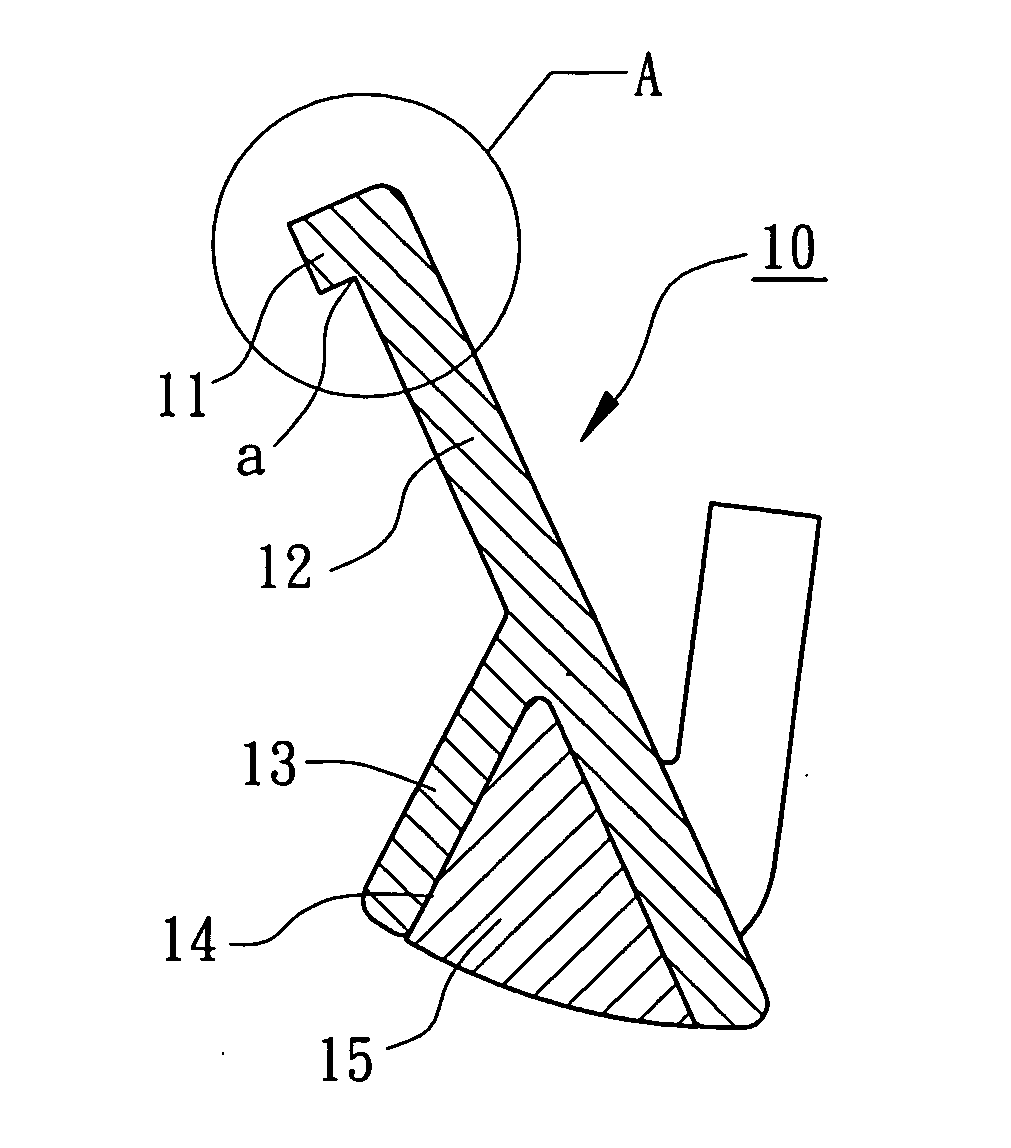

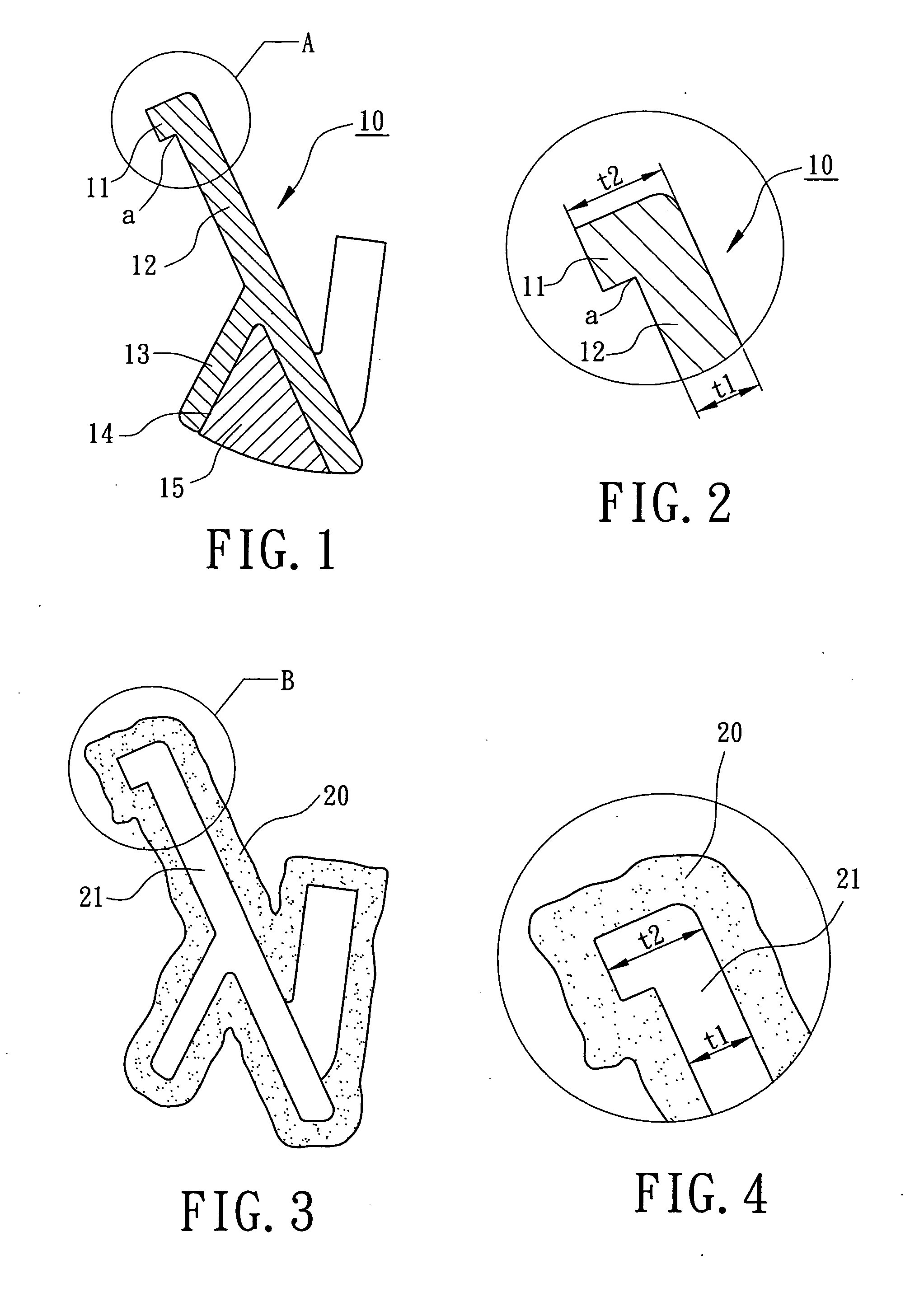

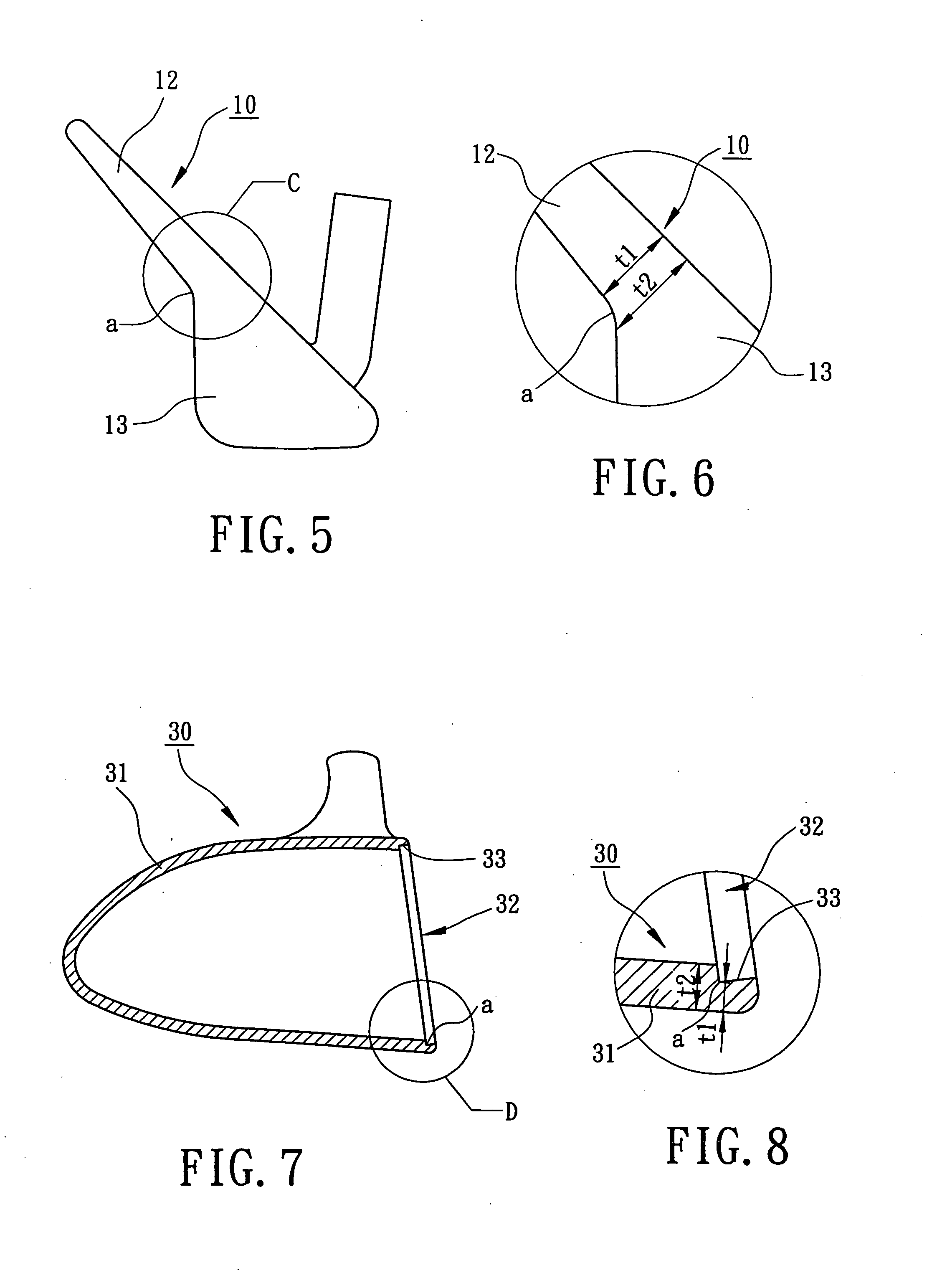

[0018] Referring initially to FIGS. 1 through 4, a golf club head structure in accordance with a first embodiment of the present invention includes a club head body 10 pertaining to an iron-type club head integrally formed with a single member and made of Fe—Mn—Al alloy. The single member of the club head body 10 includes an annular flange 11, a flat plate portion 12, a weight portion 13 and a compartment 14. In assembling, the compartment 14 is adapted to receive a weight member 15 for adjusting a center of gravity of the club head body 10. Each of the club head sections has two adjacent portions gradually changing in thickness, a connecting portion of the flat plate portion 12 to the annular flange 11 or the flat plate portion 12 to the weight portion 13 for example.

[0019] Referring again to FIG. 3, a slurry shell 20 can be made by dewaxing a wax pattern (not shown) of the club head body 10. The construction of the slurry shell 20 has a cavity 21 configured with an inner space co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com