Microscope imaging apparatus and biological-specimen examination system

a microscope and imaging apparatus technology, applied in the direction of instruments, measurement devices, scientific instruments, etc., can solve the problem of taking a long time to examine the entire micropla

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0124] Next, a first embodiment of the present invention will be described. Here, a measurement procedure will be described using FIG. 7.

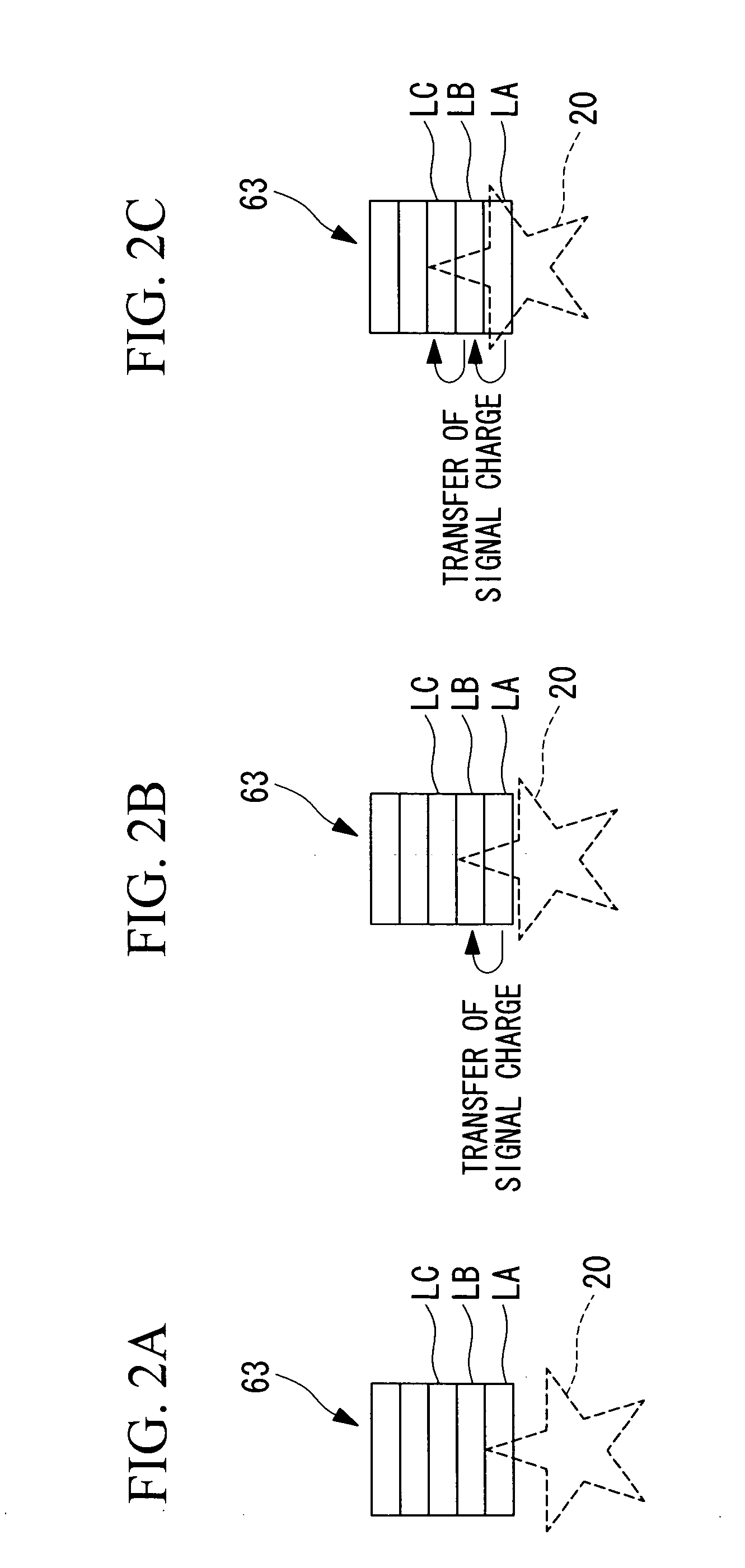

[0125]FIG. 7 is a flowchart showing the measurement procedure in this embodiment. FIGS. 8A to 8C show the relationship between the brightness of the specimen 20 and the output level from the imaging device 63. FIG. 8A shows the relationship between the brightness obtained in a first scan and the output level, FIG. 8B shows the relationship between the brightness obtained in a second scan and the output level, and FIG. 8C shows the dependency of the brightness obtained in the first and second scans no the output level.

[0126] First, the first scan (image acquisition) is performed to acquire an image of the specimen 20 (step S1). This corresponds to the prescan.

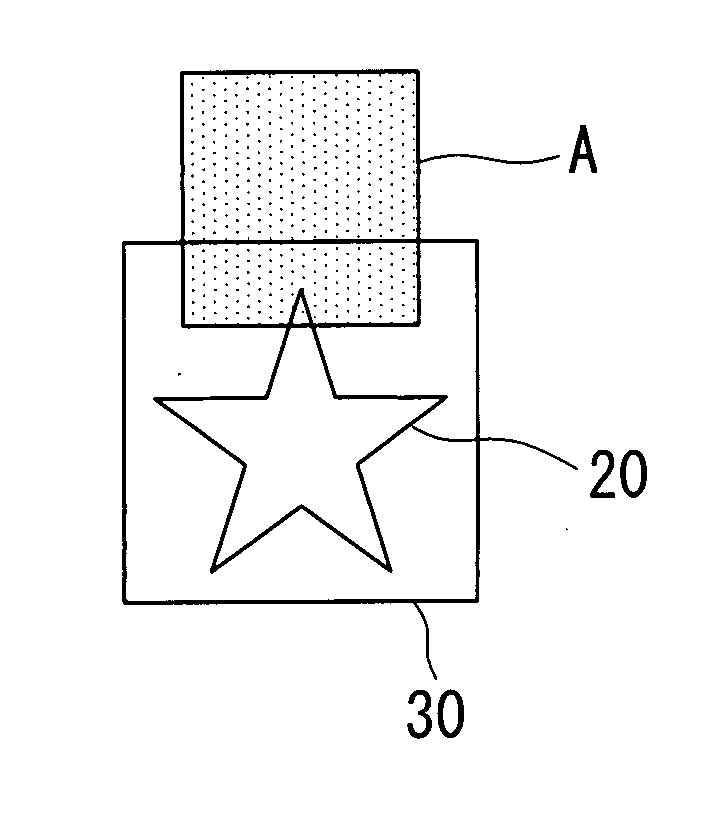

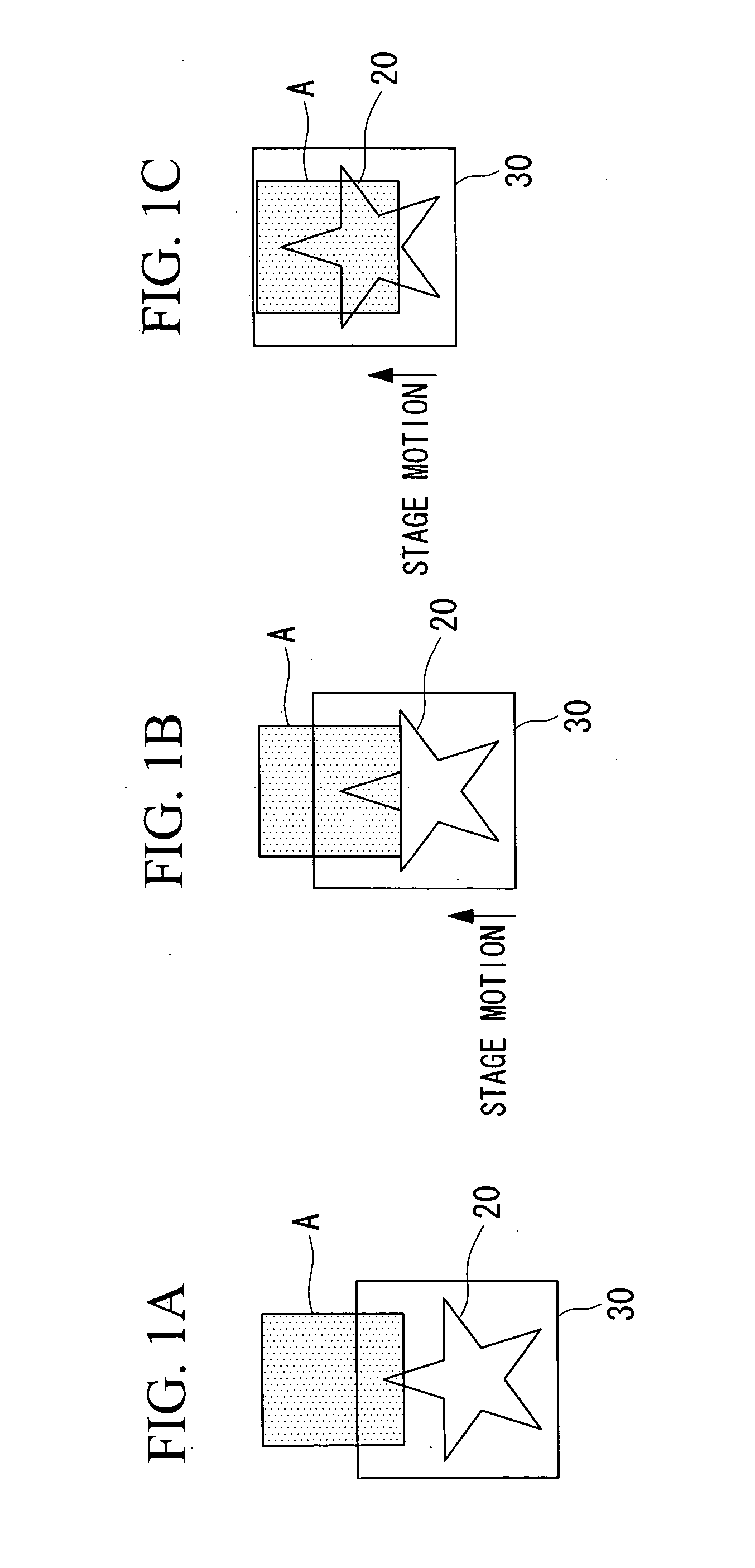

[0127] In this step, while the specimen 20 (stage 30) is moved from position a to position b shown in FIG. 6, the specimen 20 is imaged with a predetermined exposure time.

[0128] The image a...

second embodiment

[0154] Next, a second embodiment of the present invention will be described with reference to FIGS. 11 to 13.

[0155] The basic structure of the microscope imaging apparatus of this embodiment is the same as that of the first embodiment, but the method of measuring the specimen is different from that in the first embodiment. Therefore, in this embodiment, only the method of measuring the specimen shall be described, using FIGS. 11 to 13, and a description of the TDI method and so on shall be omitted.

[0156]FIG. 11 depicts the overall configuration of a microscope imaging apparatus 110 of this embodiment.

[0157] As shown in FIG. 11, the microscope imaging apparatus 110 includes a stage 30, an illumination unit 40, and an image-acquisition unit 160. The stage 30 holds a specimen 20 and is moveable. The illumination unit 40 irradiates the specimen 20 with illumination light. The image-acquisition unit 160 acquires signal light emitted from the region irradiated with illumination and mea...

third embodiment

[0174] Next, a third embodiment will be described with reference to FIGS. 14 and 15.

[0175] The basic configuration of the microscope imaging apparatus of this embodiment is the same as that in the first embodiment, but the configuration of the image-acquisition unit is different from the first embodiment. Therefore, in this embodiment only the image-acquisition unit will be described using FIGS. 14 and 15, and a description of the illumination unit and so on shall be omitted.

[0176]FIG. 14 shows the overall configuration of a microscope imaging apparatus 210 in this embodiment.

[0177] As shown in FIG. 14, the microscope imaging apparatus 210 includes a stage 30, an illumination unit 40, and an image-acquisition unit 260. The stage 30 holds a specimen 20 and is moveable. The illumination unit 40 irradiates the specimen 20 with illumination light. The image-acquisition unit 260 acquires signal light emitted from the region irradiated with the illumination light and measures it.

[0178...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com