Multilayered gloves having enhanced barrier protection

a multi-layer glove and protection technology, applied in protective garments, applications, surgery, etc., can solve the problem of glaring visual indication to users when the outer layer is breached, and achieve the effect of enhancing barrier protection, eliminating hole defects, and ensuring the same protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

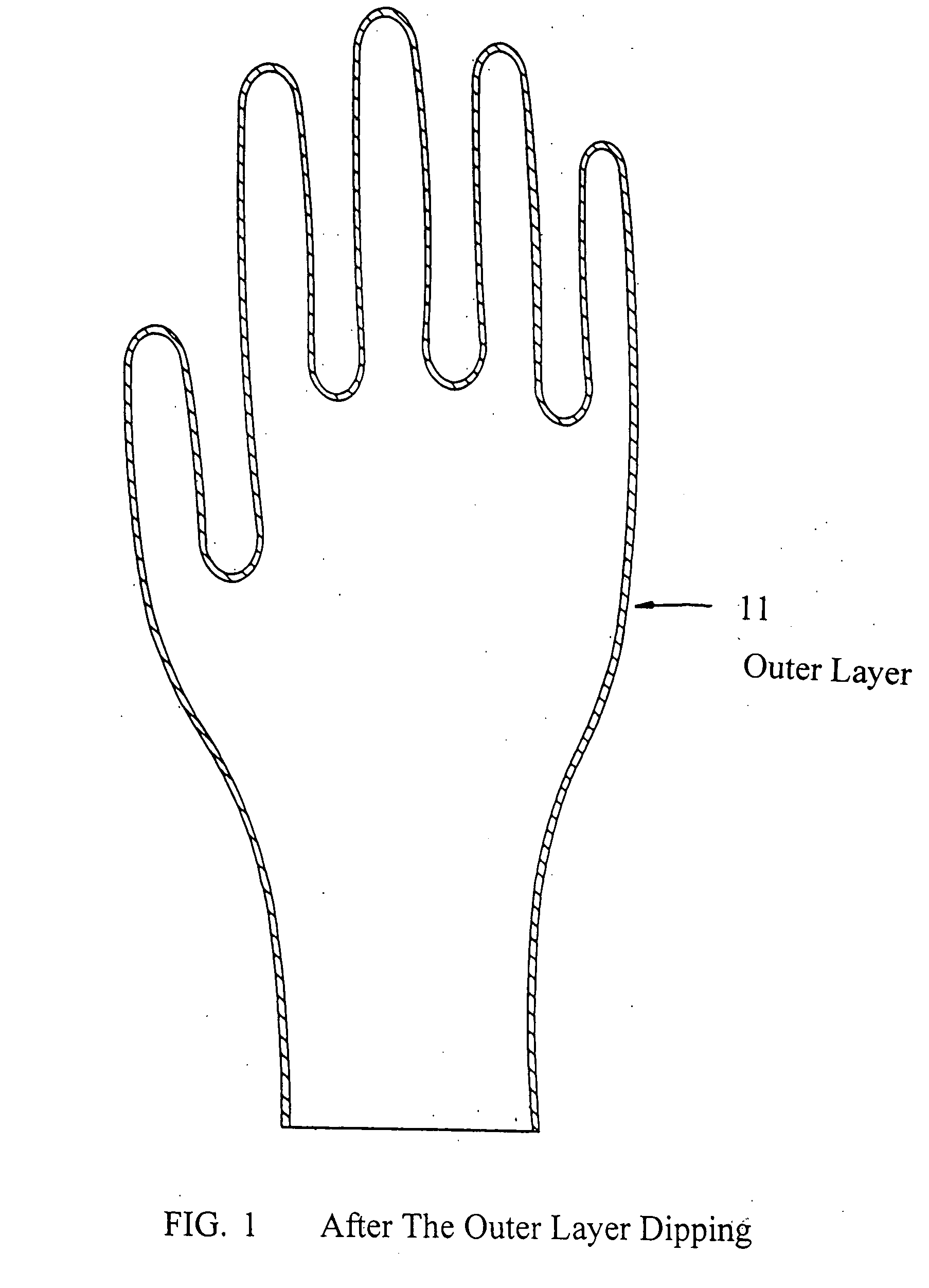

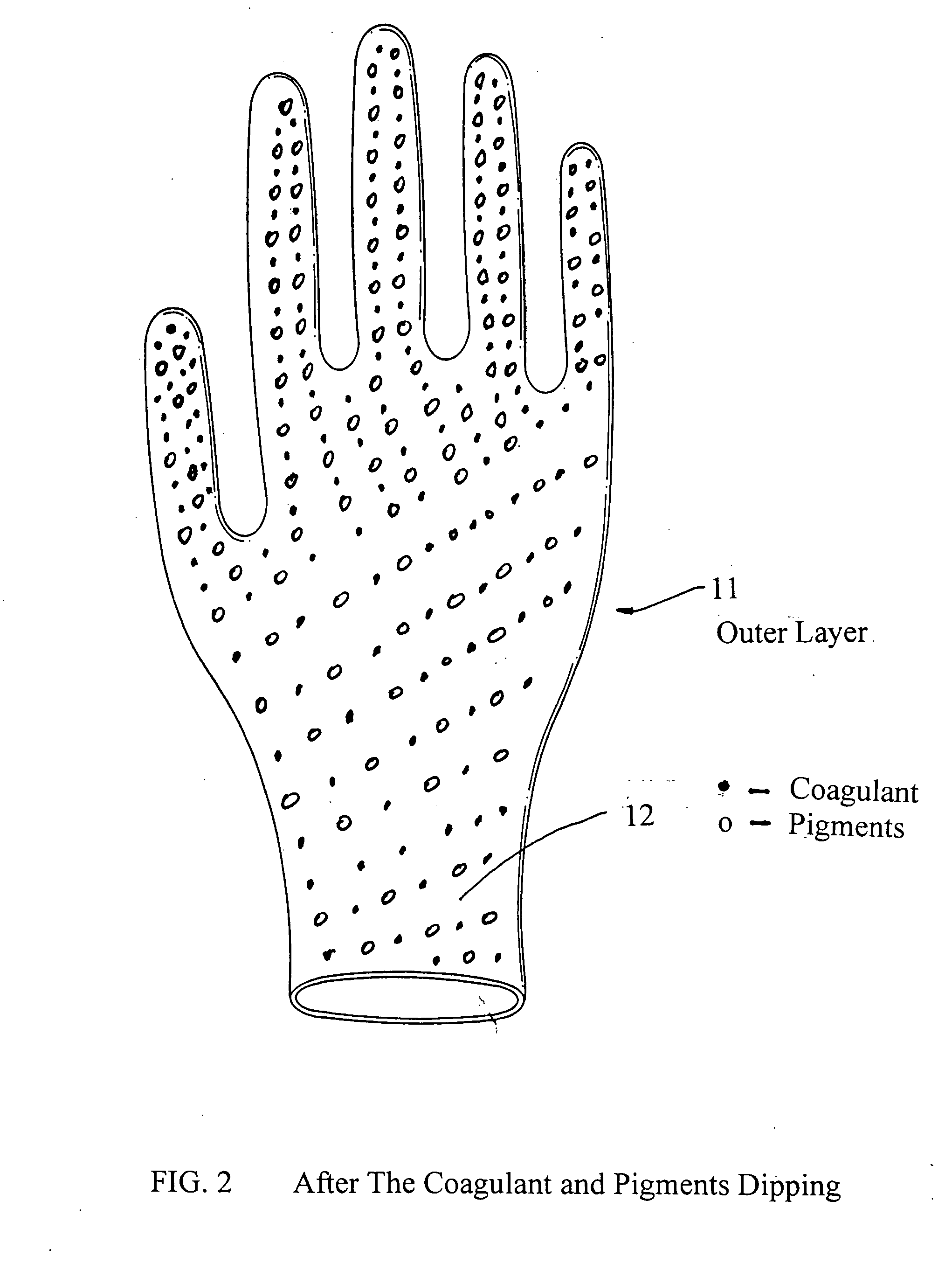

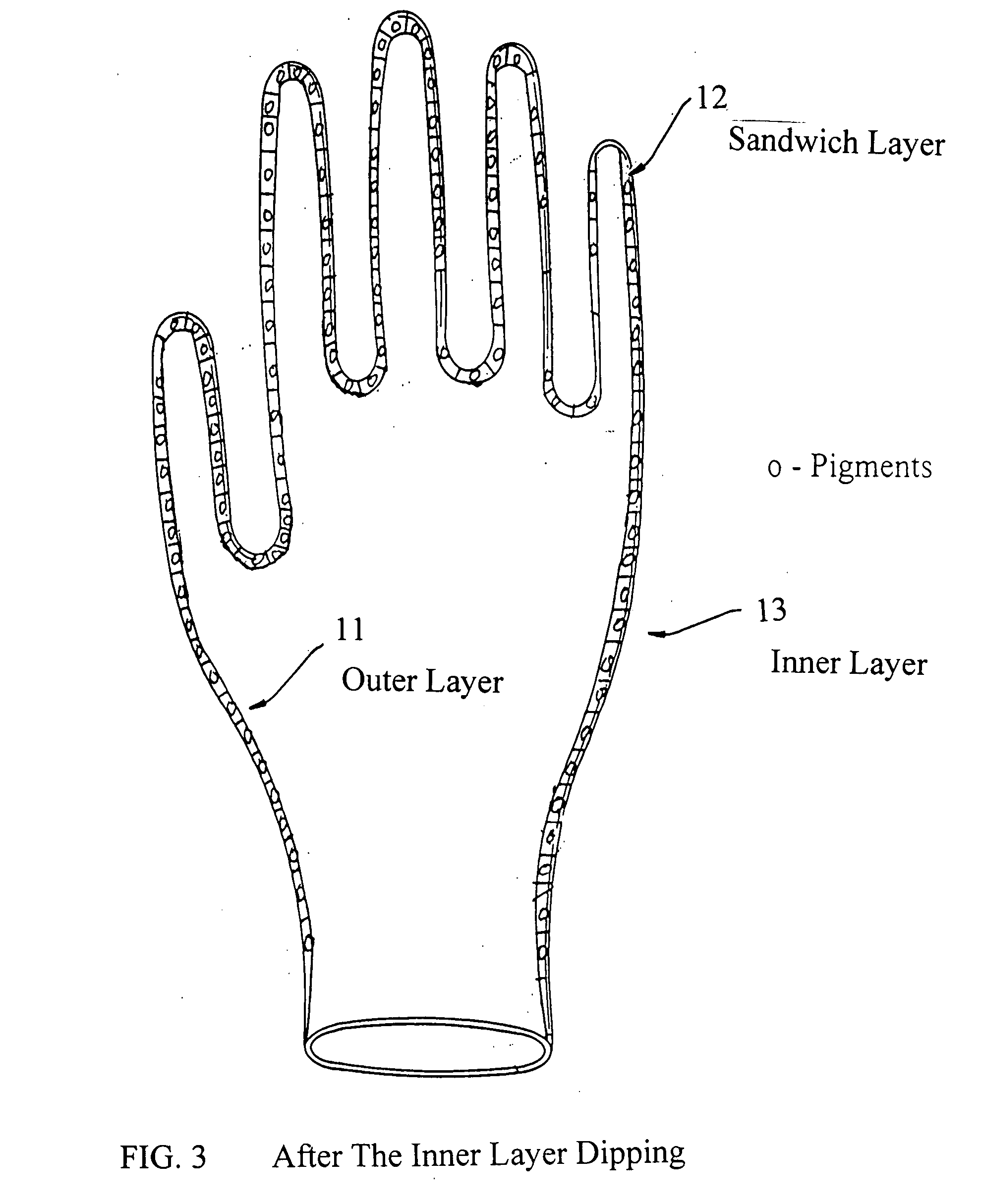

[0027] As shown in FIGS. 4 and 5, the present invention relates to a type of multilayered medical glove 4, comprising an outer layer 11, an inner layer 13, and a sandwich layer 12 between the outer layer 11 and the inner layer 13. The outer layer has the longest length than all the other layers. The sandwich layer is the shortest. The inner layer is longer than the sandwich layer but shorter than the outer layer.

[0028] Surgical gloves and examination gloves have different thickness requirements. Surgical glove thickness of the foregoing outer layer 11 and inner layer 13 is preferably 0.05 mm or more respectively in compliance with the regulations of ASTM D 3577 to achieve a minimum glove thickness of 0.10 mm. The sandwich layer 12 is designed to cover most portions of the inner layer from the finger tip to the wrist. The thickness is less than 0.01 mm. Examination glove thickness of the foregoing outer layer 11 and inner layer 13 is preferably 0.04 mm or more respectively in compli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Force | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Color | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com