A kind of rain-resistant rubber sole material and preparation method thereof

A technology for rubber sole and rain resistance, applied in the field of sole materials, can solve the problems of poor rain resistance and mechanical properties, and achieve the effects of improving flame retardancy, improving rain resistance and expanding layer spacing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

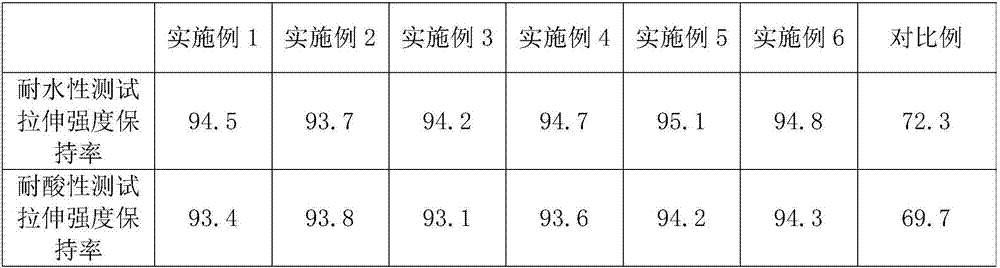

Examples

Embodiment 1

[0026] The rain-resistant rubber sole material comprises the following components in parts by weight: 52 parts of BR, 8.5 parts of EVA, 10.5 parts of SBR, 0.8 parts of antioxidant A, 2.1 parts of accelerator M, 13.5 parts of naphthenic oil, and 25 parts of white carbon black , 1.6 parts of sulfur, 1.5 parts of PEG, 0.9 parts of coumarone, 2.4 parts of 4,4'-oxobisbenzenesulfonyl hydrazide, 9.5 parts of modified layered magnesium phosphate, and 1 part of zinc stearate.

[0027] The steps of its preparation method are as follows:

[0028] 1) Add magnesium nitrate to deionized water, stir until completely dissolved, add hydrofluoric acid with a mass concentration of 30%, and after magnetic stirring for 30 minutes, add phosphoric acid with a mass concentration of 80%, and magnetically stir for 48 hours to remove hydrofluoric acid Finally, a white product was obtained, which was repeatedly washed with deionized water after suction filtration, and dried in an oven at 70°C to obtain l...

Embodiment 2

[0033] Rain-resistant rubber sole material, comprising the following components in parts by weight: 55 parts of BR, 9 parts of EVA, 10 parts of SBR, 0.5 parts of anti-aging agent A, 2.5 parts of accelerator M, 15 parts of naphthenic oil, 23 parts of white carbon black , 1.2 parts of sulfur, 1.7 parts of PEG, 0.7 parts of coumarone, 2.7 parts of 4,4'-oxobisbenzenesulfonyl hydrazide, 8 parts of modified layered magnesium phosphate, and 1 part of zinc stearate.

[0034] Its preparation method is with embodiment 1.

Embodiment 3

[0036] Rain-resistant rubber sole material, comprising the following components in parts by weight: 54 parts of BR, 10 parts of EVA, 12 parts of SBR, 1.5 parts of antioxidant A, 2.4 parts of accelerator M, 11 parts of naphthenic oil, 21 parts of white carbon black , 1 part of sulfur, 1.9 parts of PEG, 0.5 parts of coumarone, 2.5 parts of 4,4'-oxobisbenzenesulfonyl hydrazide, 8.5 parts of modified layered magnesium phosphate, and 1 part of zinc stearate.

[0037] Its preparation method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com