Potential shrinkage composite fibers for protective clothing, micro-bulge high-density hydrophobic knitted fabric and preparation method of micro-bulge high-density hydrophobic knitted fabric

A composite fiber and knitted fabric technology, applied in knitting, protective clothing, fiber types, etc., can solve the problems of land occupation, single disinfection form, and high hardness of protective clothing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The copolymer of caprolactam and hexamethylenediamine adipate with a relative viscosity of 3.19-3.41 (hereinafter referred to as PA66 / 6, BASF C33) is vacuum-dried at 60-100°C for 4-6 hours, so that the mass fraction of water content is Below 0.01%; the copolymer of ethylene terephthalate and ethylene glycol isophthalate-5-sodium sulfonate, isophthalic acid and polyethylene glycol (hereinafter referred to as copolymerized PET) at 120~ Airflow drying at 165°C for 4 to 6 hours to keep the water content below 0.005%; polyethylene terephthalate (hereinafter referred to as PET) at 120 to 180°C for 4 to 6 hours to make it Its water content is below 0.005%; polyamide 6 (hereinafter referred to as PA6) and polyamide 66 (hereinafter referred to as PA66) are dried at 90-120°C under the protection of nitrogen for 3-6 hours, so that the water content is 0.01%. the following.

Embodiment 2

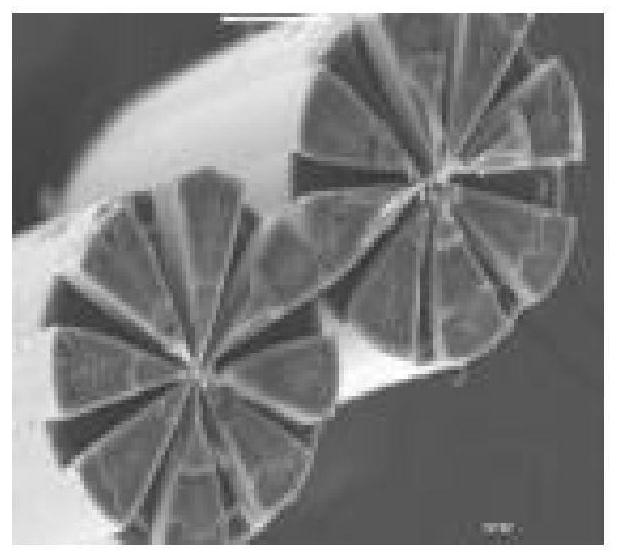

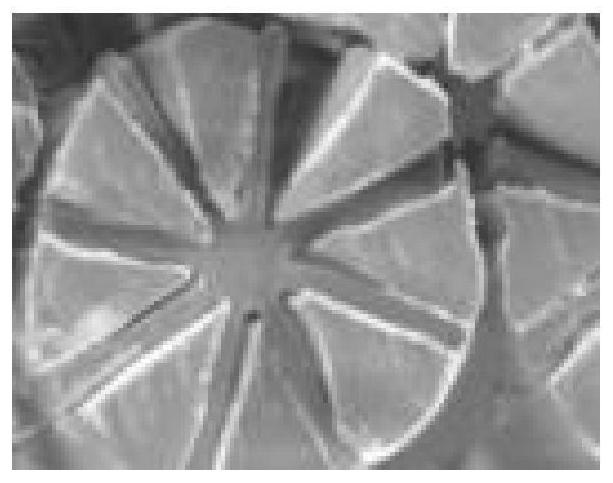

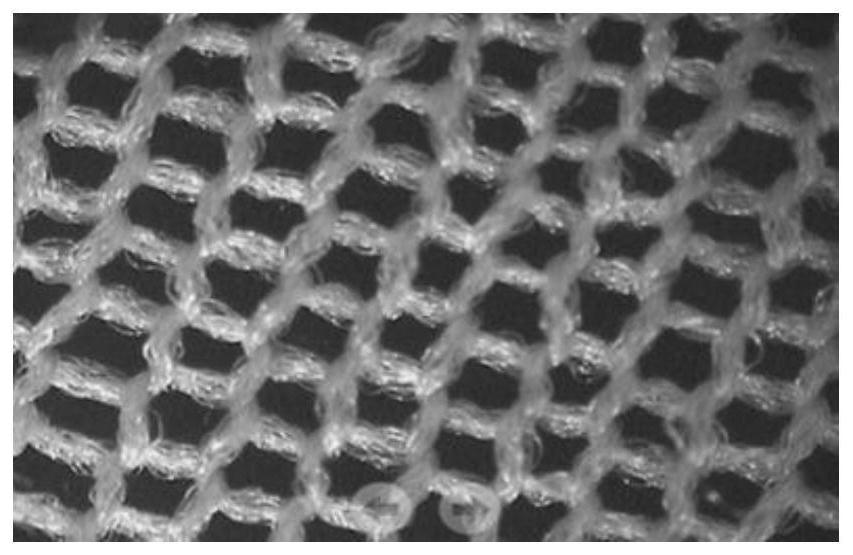

[0035] The dried PET and PA66 / 6 are respectively plasticized and melted, fed into the 8+1 type spinning assembly, cooled and formed after extrusion (such as figure 2 Shown), after drawing, it is 30% that PA66 / 6 mass fraction is obtained, and the latent shrinkage composite fiber that PET mass fraction is 70%. The composite fiber is woven into a surface density of 270 g / m with a 42-pin / inch knitting machine 2 For the knitted fabric, the fabric was treated at 120° C., 2% sodium hydroxide and dodecyldimethylbenzyl ammonium chloride aqueous solution for 40 minutes, and after drying, it was polished with 400# sandpaper to obtain a micro-raised high-density fabric. Dip-coat the high-density fabric with isopropanol solution with a concentration of 10% PDMS, then spray it with 1.0% curing agent, and then press and roll it. Dry it with infrared rays at 70°C for 10 minutes, set it with infrared rays at 120°C for 3 minutes, and cool it. After winding, a micro-raised high-density hydroph...

Embodiment 3

[0037]The dried PA66 and PA66 / 6 are respectively plasticized and melted, fed into a 4+1 type spinning assembly, cooled and formed after extrusion, and obtained after drawing with a mass fraction of PA66 / 6 of 40% and a mass fraction of PA66 of 60%. Potential to shrink composite fibers. It is 200 grams / m2 that it is woven into a surface density of 42 needles / inch knitting machine with a needle density 2 For knitted fabrics, the fabrics were treated at 100° C. in 0.2% formic acid aqueous solution for 90 minutes, and after drying, they were polished with 200# sandpaper to obtain micro-raised high-density fabrics. The high-density fabric is dip-coated with isopropanol solution with a concentration of 5% PDMS, then sprayed with 0.5% curing agent, and then rolled, dried at 120°C for 3 minutes, and set at 80°C for 5 minutes, cooled After winding, the micro-raised high-density hydrophobic knitted fabric is obtained, the fabric contact angle is equal to 131.5°, and the water staining l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com