Heat-reflection heat-insulation film and preparation method thereof

A technology of thermal insulation film and heat reflection, applied in the field of thermal insulation film, can solve the problems of reducing the use comfort and thermal insulation capacity, reducing the thermal insulation capacity of clothes, and the high price of down, etc., achieving excellent barrier protection, good biocompatibility, good The effect of thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

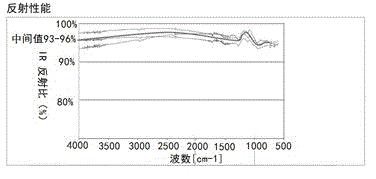

Image

Examples

Embodiment 1

[0021] A heat-reflecting thermal insulation film, the raw materials comprising: 50 parts of polyester, 30 parts of polyethylene glycol ether and 4 parts of aluminum powder in parts by weight.

[0022] The preparation method of the heat reflective thermal insulation film, the specific steps are as follows:

[0023] (1) Taking materials: Weighing each raw material according to parts by weight;

[0024] (2) Feeding: Add polyester and polyethylene glycol ether into the reaction kettle and mix and stir for 3 minutes;

[0025] (3) Add aluminum powder: add aluminum powder to the reaction kettle and stir for 20 minutes;

[0026] (4) Preparation of thermal insulation film: place the coating on the coating machine, adjust the scraper so that the angle of the scraper is 20°, and determine the thickness of the film to be 15 μm;

[0027] (5) Overmolding oven: Put the molded insulation film in an oven at 80°C and bake for 2 minutes to form;

[0028] (6) Large film rewinding: use a rewind...

Embodiment 2

[0031] A heat-reflecting thermal insulation film, the raw materials in parts by weight include: 55 parts of polyester, 35 parts of polyethylene glycol ether, and 5 parts of aluminum powder

[0032] The preparation method of the heat reflective thermal insulation film, the specific steps are as follows:

[0033] (1) Taking materials: Weighing each raw material according to parts by weight;

[0034] (2) Feeding: Add polyester and polyethylene glycol ether into the reaction kettle and mix and stir for 4 minutes;

[0035] (3) Add aluminum powder: add aluminum powder to the reaction kettle and stir for 30 minutes;

[0036] (4) Preparation of thermal insulation film: place the coating on the coating machine, adjust the scraper so that the angle of the scraper is 30°, and determine the thickness of the film to be 25 μm;

[0037] (5) Overmolding oven: Put the molded insulation film in an oven at 120°C and bake for 4 minutes to form;

[0038] (6) Large film rewinding: use a rewinder...

Embodiment 3

[0041] A heat-reflecting thermal insulation film, comprising: 60 parts of polyester, 40 parts of polyethylene glycol ether, and 6 parts of aluminum powder in parts by weight.

[0042] The preparation method of the heat reflective thermal insulation film, the specific steps are as follows:

[0043] (1) Taking materials: Weighing each raw material according to parts by weight;

[0044] (2) Feeding: Add polyester and polyethylene glycol ether into the reaction kettle and mix and stir for 5 minutes;

[0045] (3) Add aluminum powder: add aluminum powder to the reaction kettle and stir for 40 minutes;

[0046] (4) Preparation of thermal insulation film: place the coating on the coating machine, adjust the scraper so that the angle of the scraper is 45°, and determine the thickness of the film to be 35 μm;

[0047] (5) Overmolding oven: Put the molded insulation film in an oven at 160°C and bake for 5 minutes to form it;

[0048] (6) Large film rewinding: use a rewinder to rewind ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com