Stream down type ice making machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

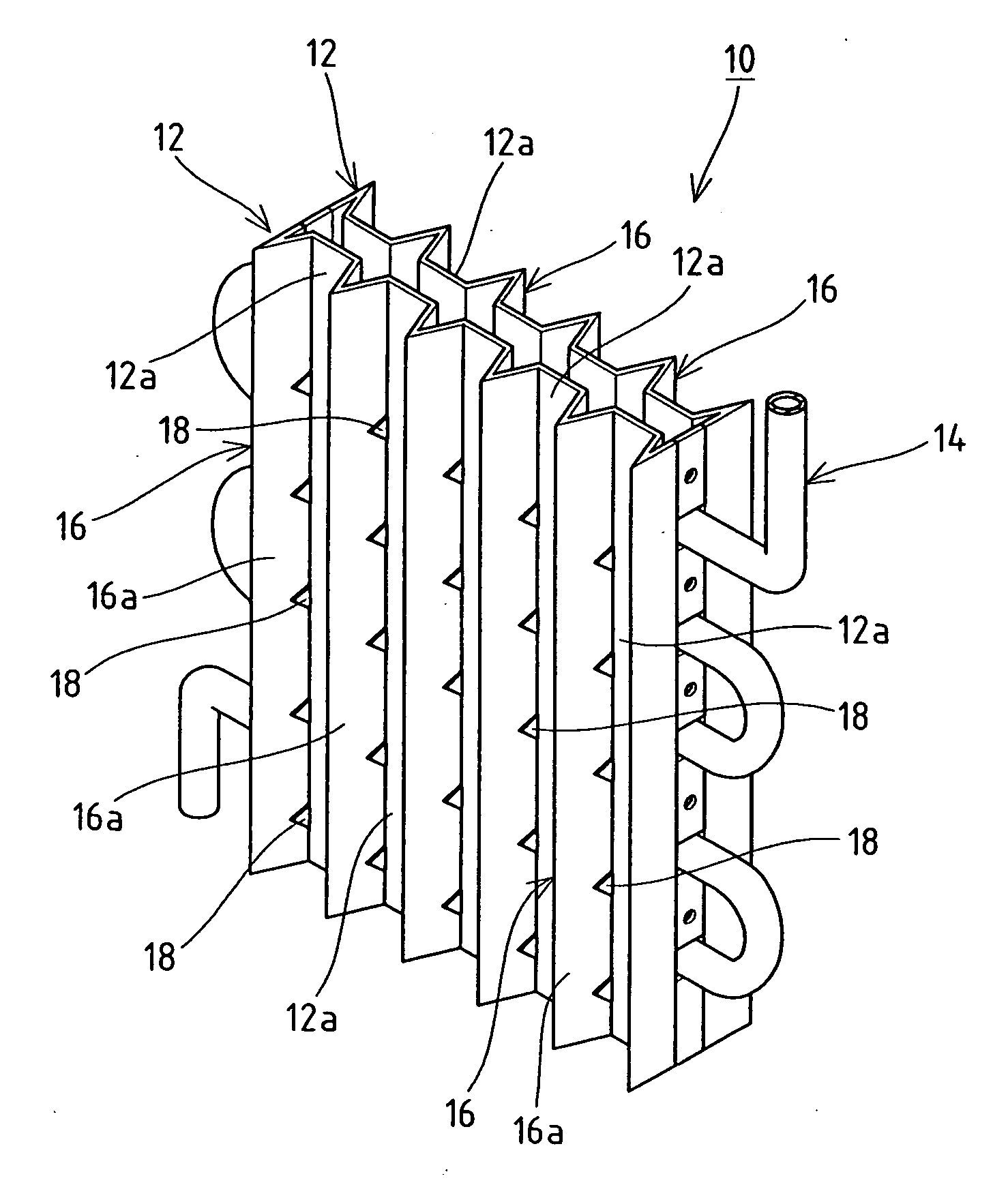

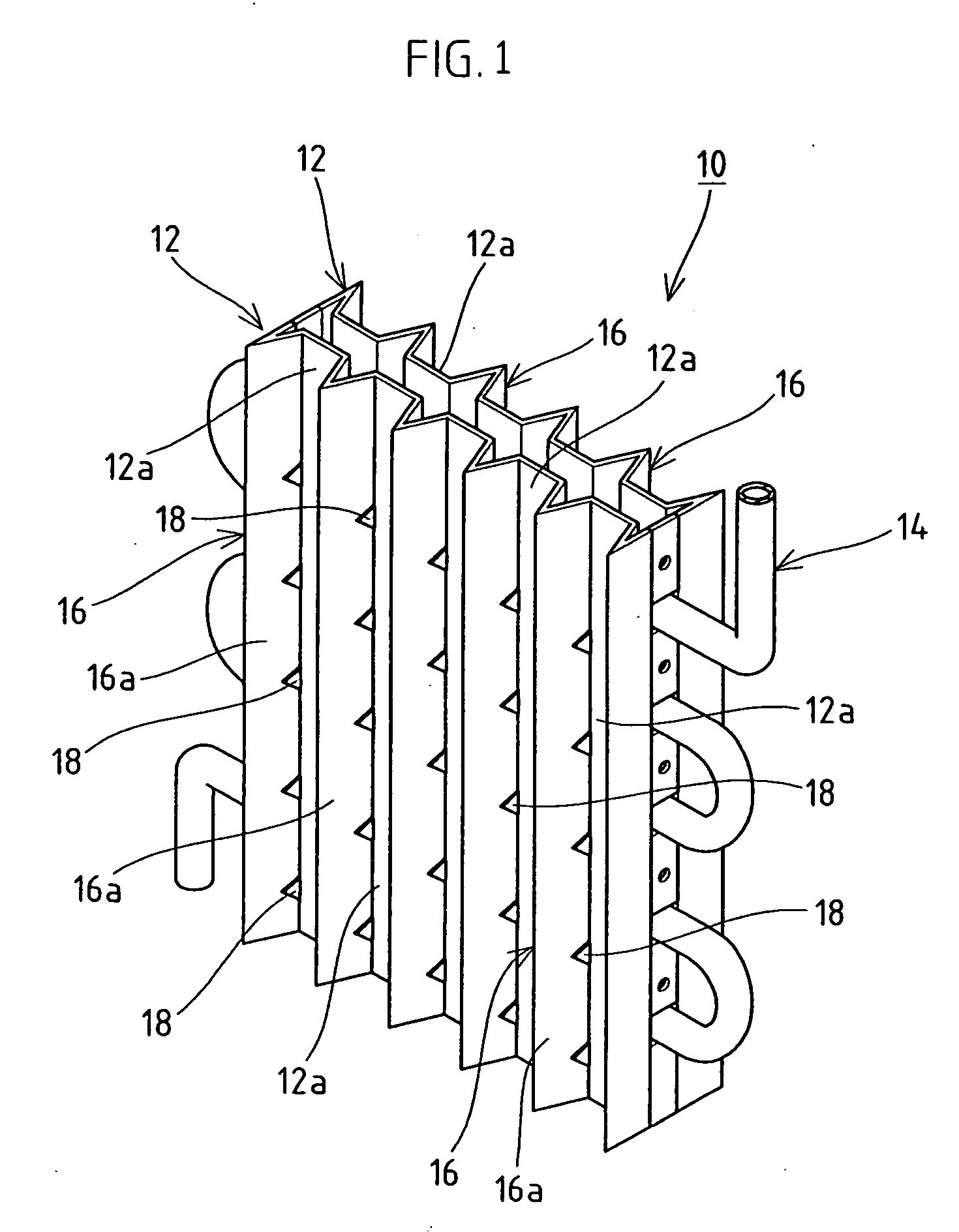

Image

Examples

first embodiment

Modification of First Embodiment

[0024] The shape of the protrusion is not limited to a triangle, but may be a shape in which at least an upper face thereof is inclined downward, and, for example, as shown in FIG. 4, it may be a straight one downwardly inclined toward the outside direction (the side being away from the ice making face 12a) from the bended edge between the ice making face 12a and the extension portion 16a. Then, also in a protrusion 20 having a straight line shape, the lump of ice C can be caused to be away from the ice making face 12a along a slope 20a thereof. In addition, while the projecting dimensions from the extension portion 16a of the protrusion 20 are suppressed to be small, the position at the tip (the lower end of the slope) can be separated from the ice making face 12a sufficiently, thereby allowing the lump of ice C to fall promptly.

[0025] Although in the first embodiment the protrusions are provided opposite to the extension portions (the vertical ribs...

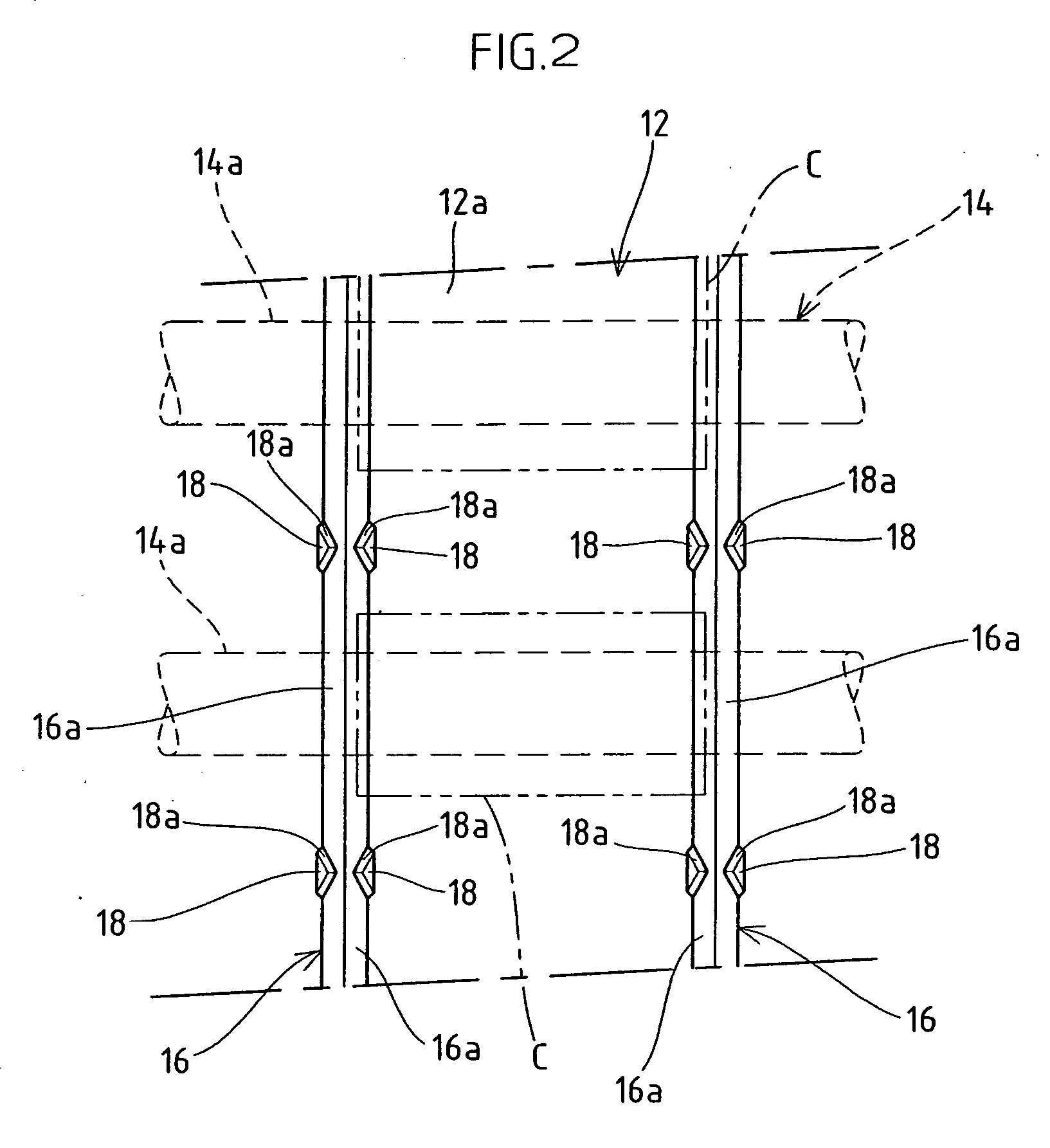

second embodiment

[0026]FIG. 5 shows an ice making portion of a stream down type ice making machine according to the second embodiment. In addition, concerning the same members as those of the first embodiment described above, the same numerals are given and the detailed description thereof will be omitted.

[0027] In an ice making portion 22 according to the second embodiment, the protrusion 18 formed in each extension portion 16a in the vertical rib 16 provided in the ice making plate 12 is set in the position corresponding to the evaporator 14 arranged in the back face of the ice making plate 12. Namely, in the ice making process, in the ice making portion 22 of the second embodiment, the protrusions 18 and 18 are included by the lump of ice C produced in the ice making region. Then, moving to the deicing process, where a hot gas is cyclically supplied to the evaporator 14 and a deicing-water is supplied to the back face of the ice making plate 12, and when the frozen portion between the ice making...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com