Security tag and process for making same

a technology of security tags and process steps, applied in the field of resonant tags, can solve problems such as excessive waste of metallic foils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

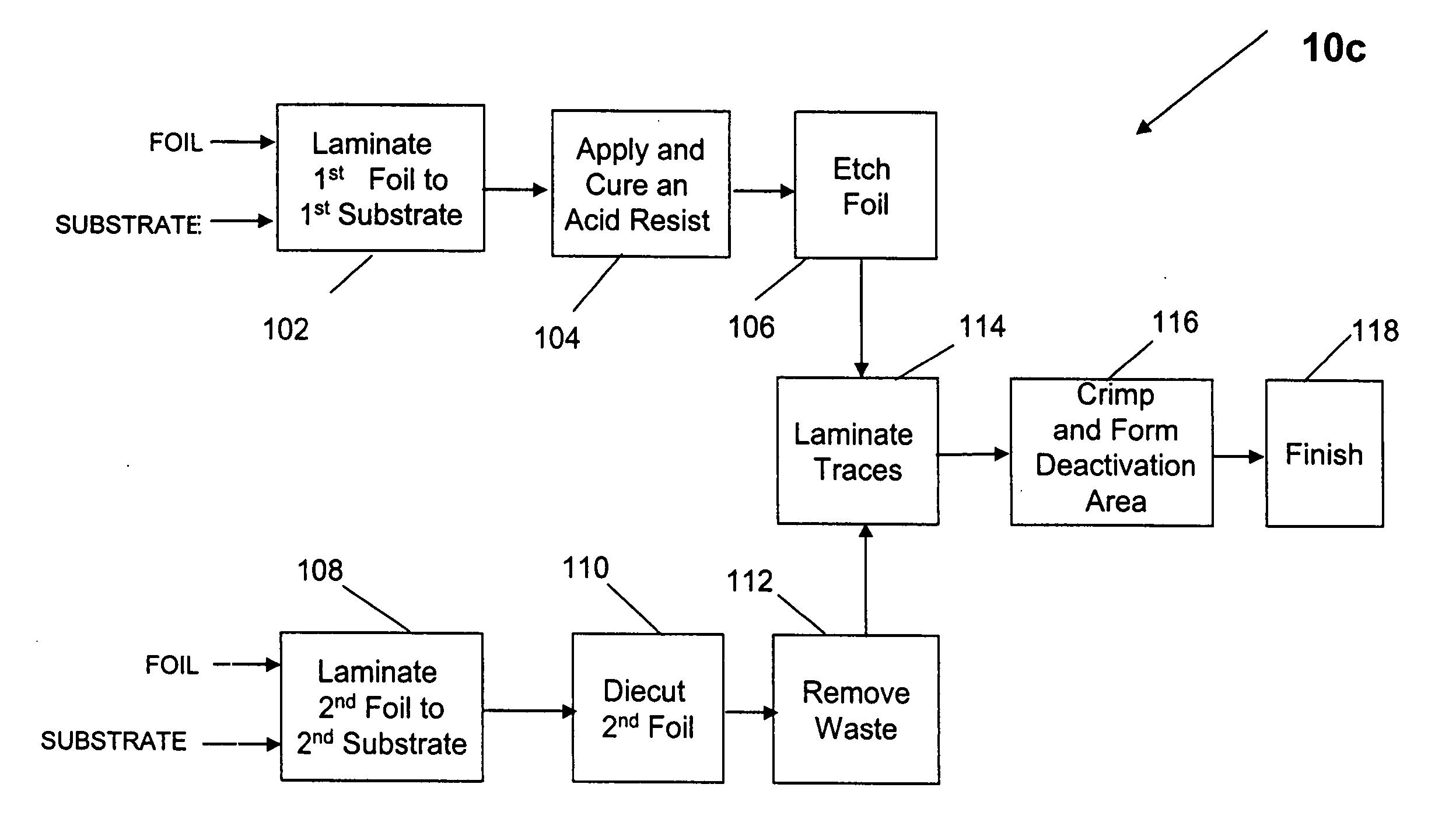

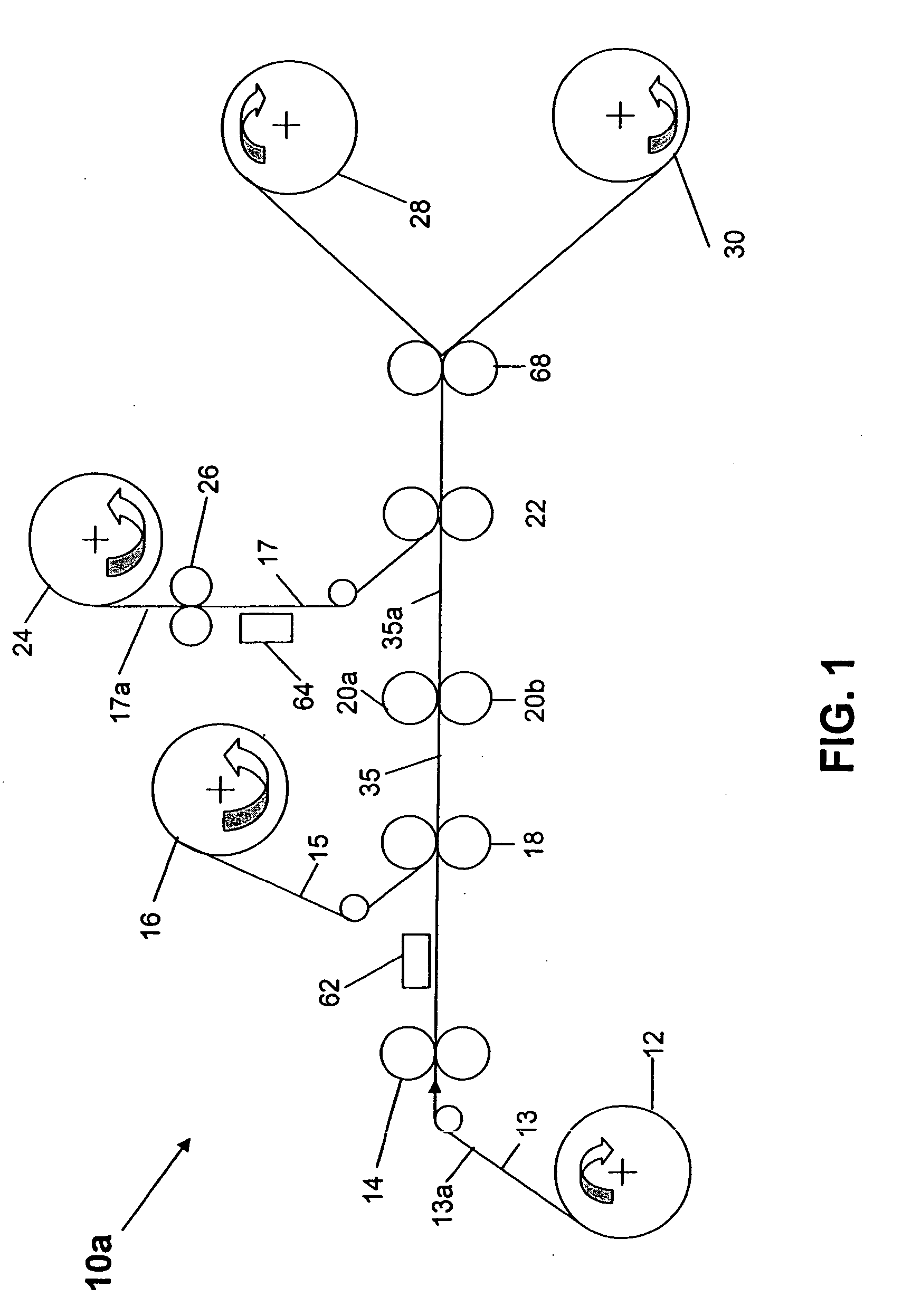

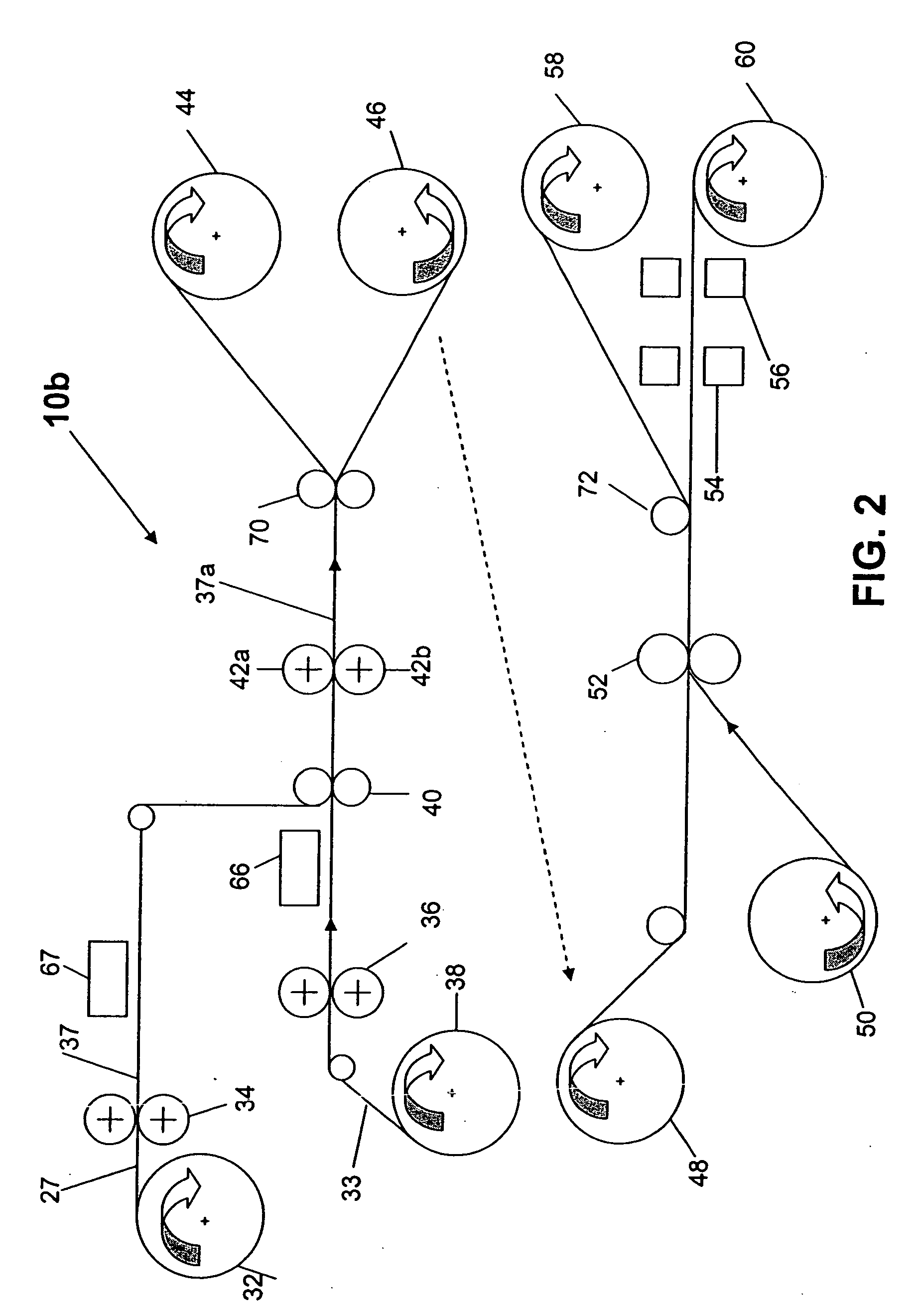

[0021] Referring to the drawings, wherein like numerals are used to indicate like elements throughout the several figures, the use of the indefinite article “a” may indicate a quantity of one, or more than one, of an element, and the use of the article “or” indicates a Boolean “exclusive or” function there is shown in FIGS. 1 and 3A-3E a process 10a for making a resonant tag according to a first preferred embodiment.

[0022] According to a first preferred embodiment, a first substrate 13 for the resonant tag is stored on a first unwind roll 12. Preferably, the first substrate 13 is paper which has been calendared in order to provide a densified sheet having a smooth finish and a uniform thickness. An adhesive is applied to a surface 13a of the first substrate 13 as the first substrate 13 is removed from the unwind roll 12 (FIG. 3A). The adhesive forms a first adhesive layer 19 in a first predetermined pattern on the surface 13a of the substrate 13. Preferably, the adhesive forming th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com