Briquette for use as steelmaking material and method of manufacturing the same

a technology of briquettes and steelmaking materials, applied in the direction of process efficiency improvement, etc., can solve the problems of reducing the use of reducing agents in the steelmaking process, and achieve the effect of reducing and increasing the use of reducing agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

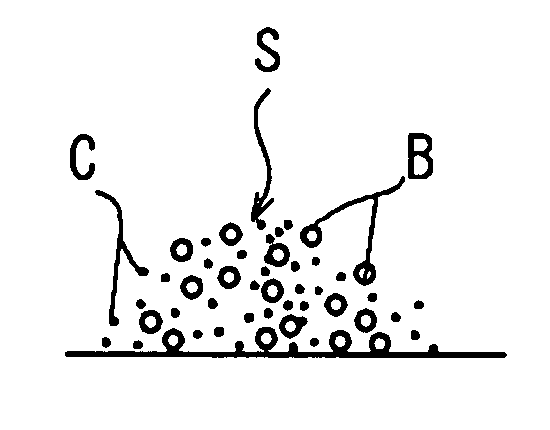

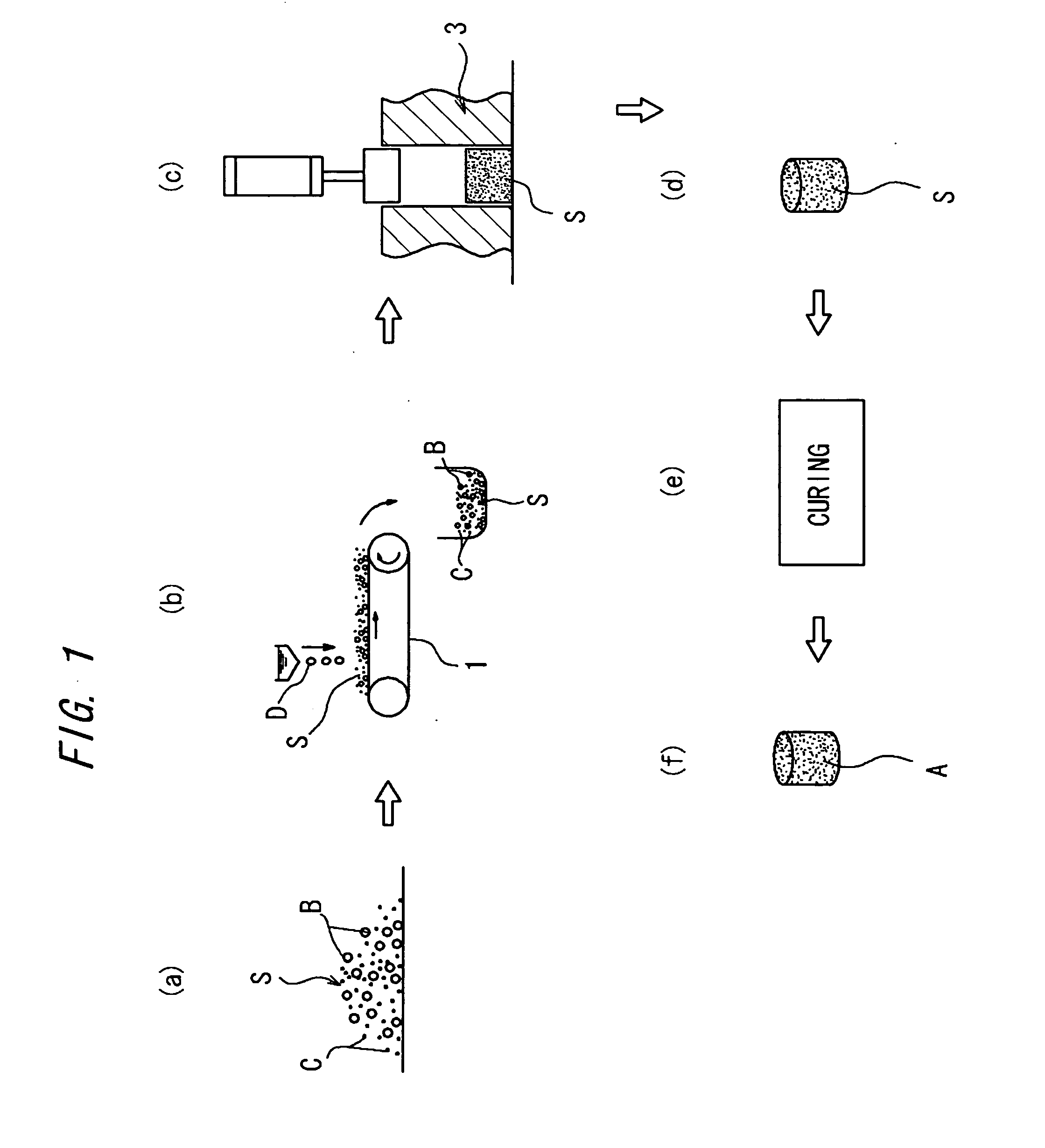

[0026]FIG. 1 is a step chart illustrating a method of manufacturing a briquette for use as steelmaking material according to the invention. In the manufacture of a briquette A, shot waste S (FIG. 1(a)) resulting from shot blasting a ferrous metal is first transported by means of a belt conveyor 1, while a solidification assistant D in liquid form is added dropwise to the shot waste S (FIG. 1(b)).

[0027] The shot waste S includes a great number of spent shot beads B thinned down to less than a predetermined particle size by the shot blasting process, a ferrous powder metal C and the like. The powder metal contains oxidized powder iron in an amount of 60 to 65 wt %. A 100% sodium silicate solution is used as the solidification assistant D.

[0028] Next, the shot waste S admixed with the solidification assistant D is compression molded by means of a press using a mold 3 (FIG. 1(c), FIG. 1(d)). The compression molding allows the solidification assistant D added to the shot waste S to perm...

second embodiment

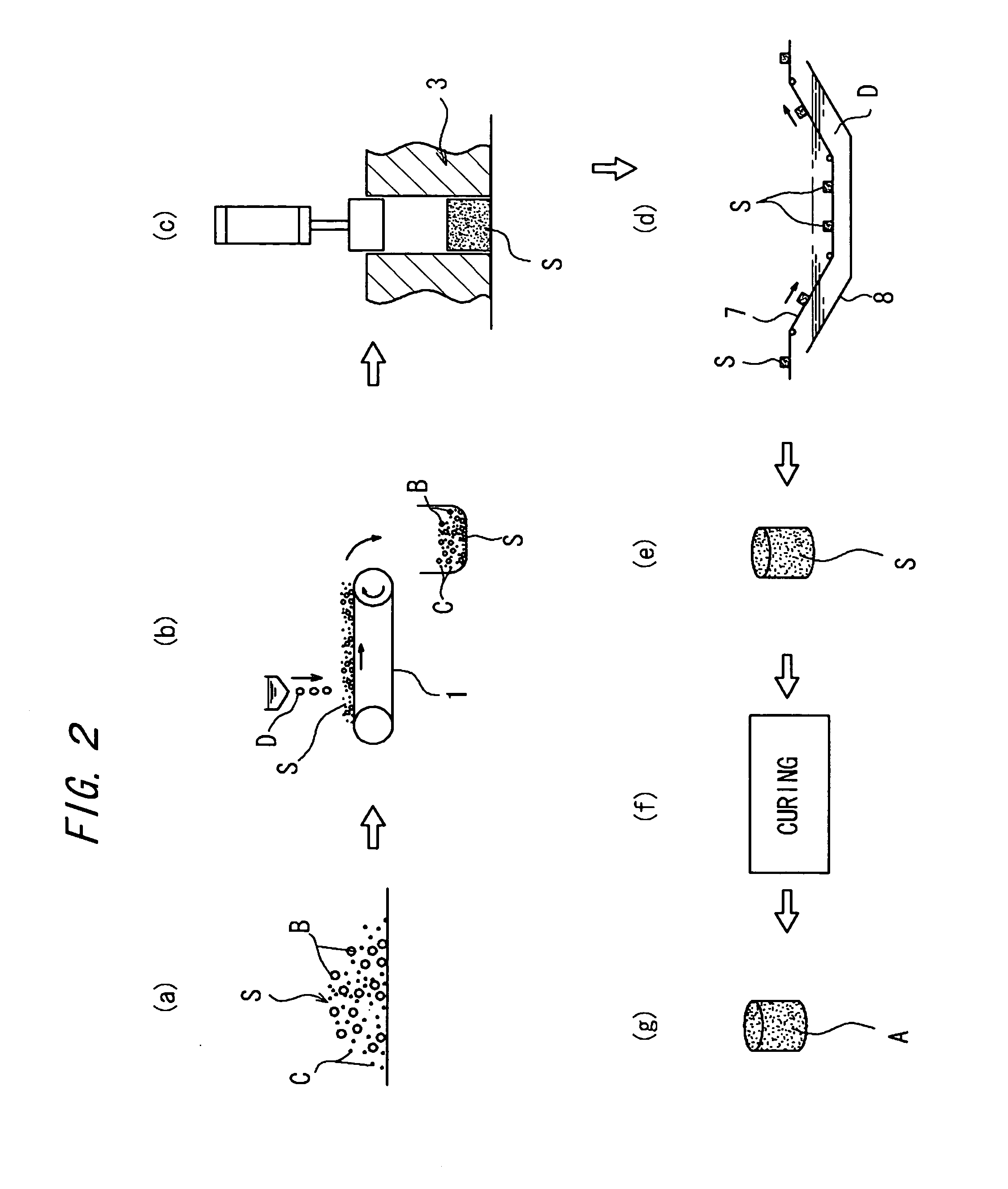

[0032]FIG. 2 is a step chart illustrating a method of manufacturing a briquette for use as steelmaking material according to the invention. This embodiment differs from the embodiment shown in FIG. 1 in that the manufacture process further includes a step of impregnating the solidification assistant D into the shot waste S, the step being interposed between the step of compression molding the shot waste S and the step of drying the compression molded shot waste S.

[0033] The impregnation of the solidification assistant D is performed as follows, for example. As carried on a belt conveyor 7, the compression molded shot waste S is dipped in the solidification assistant D filled in a tank 8 (FIG. 2(d)). Sodium silicate diluted with water is used as the solidification assistant D filled in the tank 8. Thus is ensured a good permeability of the solidification assistant D into the compression molded shot waste S. According to this embodiment, the mechanical strength of the briquette A is f...

third embodiment

[0037]FIG. 4 is a step chart illustrating a method of manufacturing a briquette for use as steelmaking material according to the invention. In the manufacture of the briquette A, cotton-like agglomerations M are first prepared by sprinkling the shot waste S on cutting sludge E (FIG. 4(a)) being transported on the belt conveyor 1, the cutting sludge resulting from cutting a ferrous metal. The cotton-like agglomerations are admixed with the shot waste S (FIG. 4(b)). The cutting sludge E is a cotton-like material containing the cutting residue particles and the cutting fluid. The shot waste S results from shot blasting a ferrous metal, containing spent shot beads thinned down to less than a predetermined particle size by the shot blasting process and a powder material containing oxidized powder iron in an amount of 60 to 65 wt %. A mixing ratio of the shot waste S is 10 to 30 wt %. If the cotton-like agglomerations M contains the shot waste S in an amount of less than 10 wt %, the briq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wt % | aaaaa | aaaaa |

| wt % | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com