Fire fighting nozzle and method including pressure regulation, chemical and eduction features

a technology of eduction features and nozzles, which is applied in the direction of combustion processes, burners, combustion types, etc., can solve the problems of decreasing the effective size of the nozzle discharge port, and achieve the enhancement of eduction of the second fluid or foam concentrate, diminishing cross sectional area, and enhancing eduction features.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

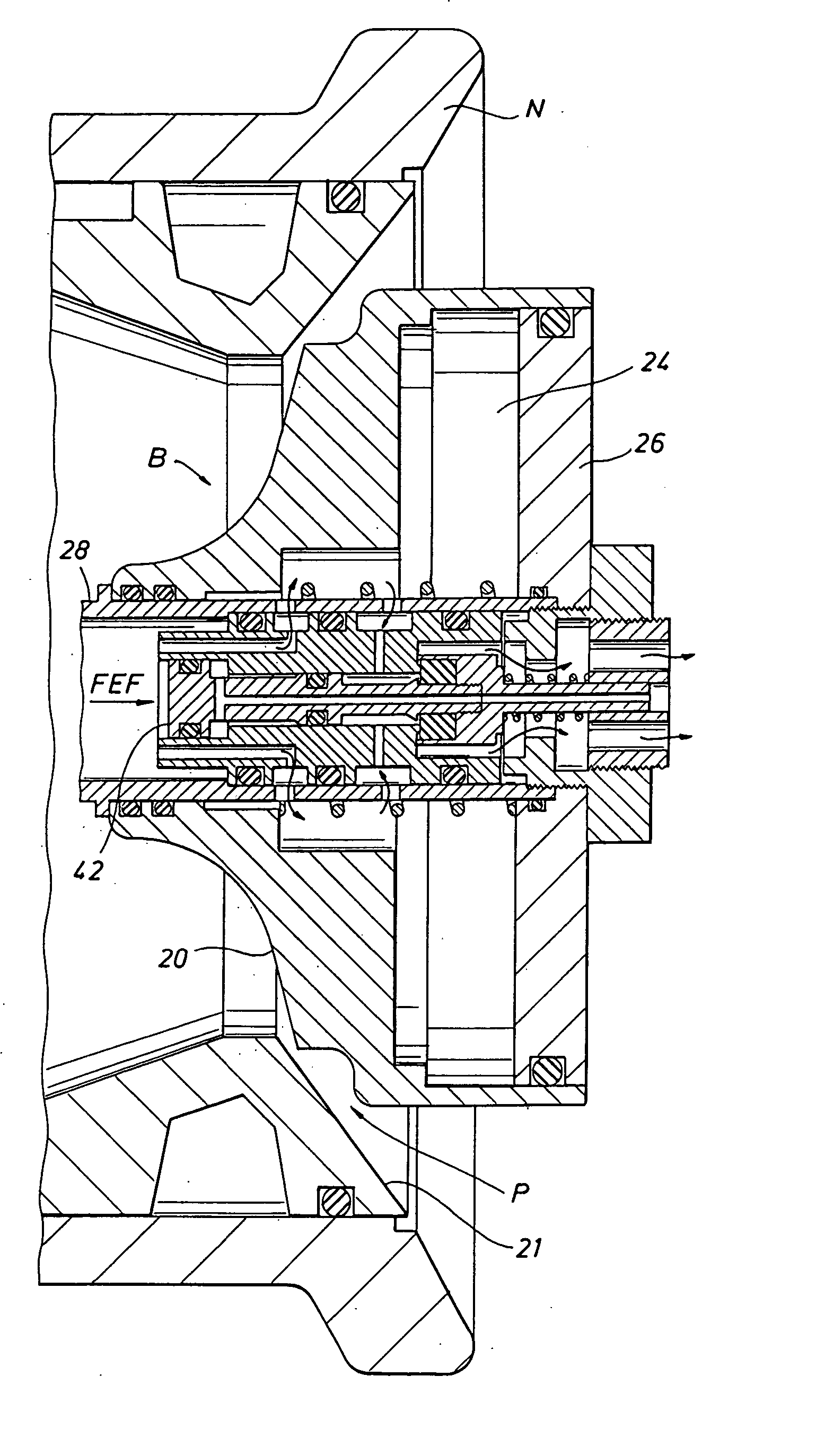

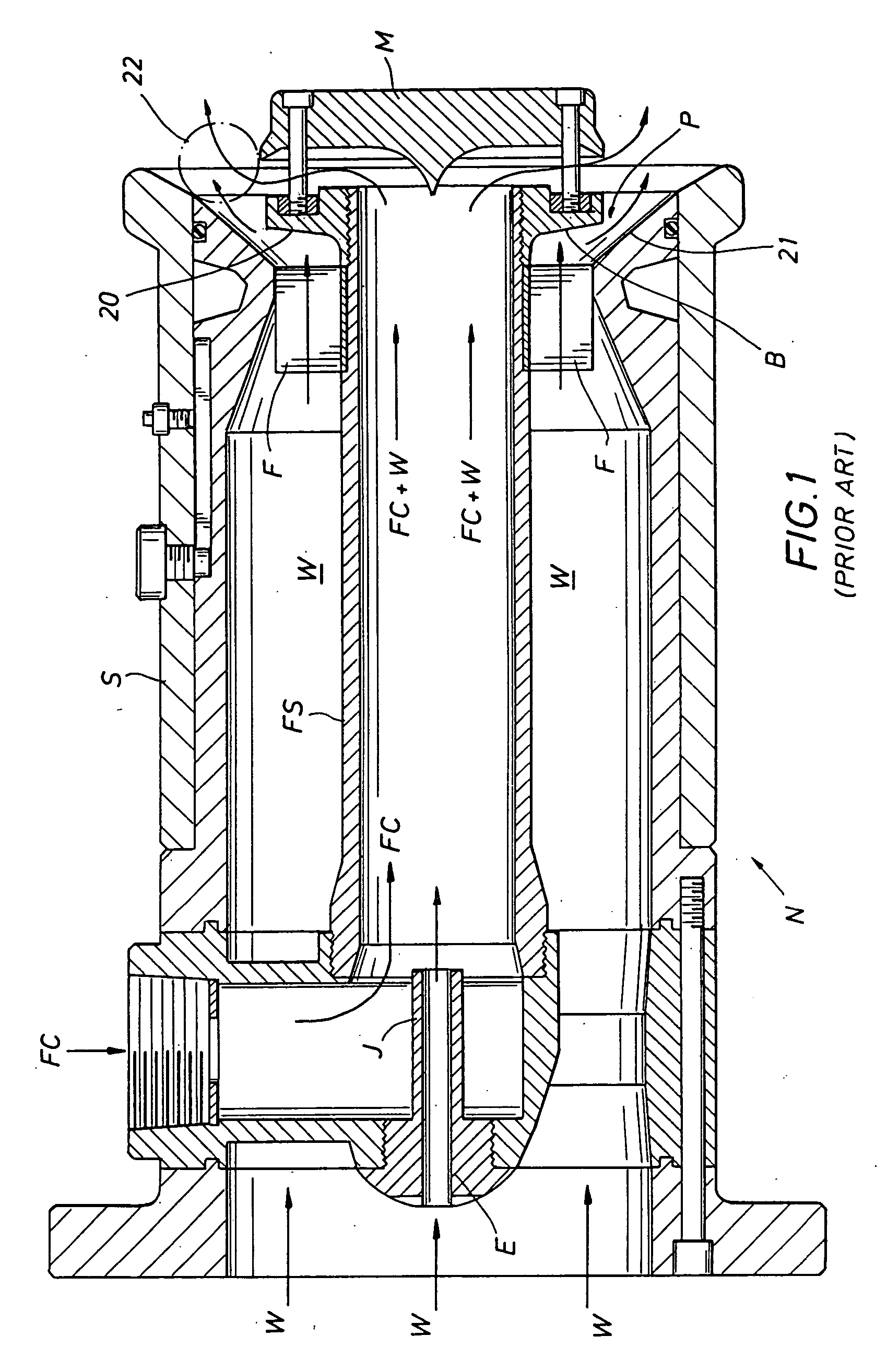

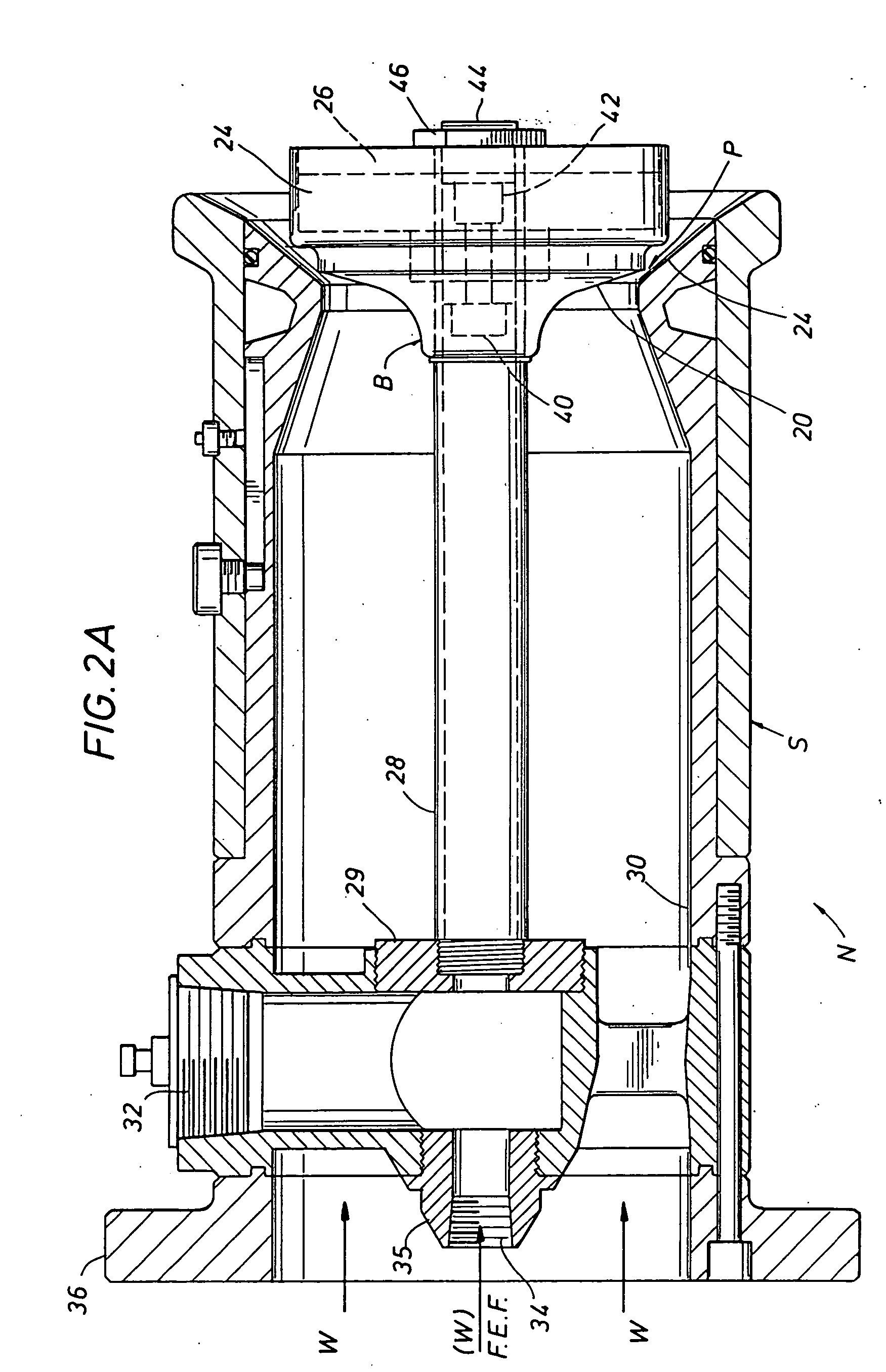

[0048] In general, a nozzle having an “adjustable” baffle in order to discharge fire extinguishing fluid at a targeted pressure requires a biasing means opposing a natural movement of an adjustable baffle outwards in response to fluid pressure, which outward movement tends to open the effective size of the discharge port. Most simply the biasing means biases with a backward force equal to the force of the desired or targeted fluid pressure upon the forward baffle surfaces. Hence baffle forward movement balances against baffle backward bias pressure at the targeted pressure. Forward baffle surfaces are surfaces that the baffle presents to the fire extinguishing fluid moving through and out of the discharge port. In theory, the biasing force could be provided by a spring that, over the adjustment range of the baffle between its end points, which may be no more than approximately one half of an inch, presents an essentially constant biasing force at the targeted pressure. The target pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com