Closing device

a technology of sealing device and sealing bag, which is applied in the direction of flexible container closure, transportation and packaging, mechanical equipment, etc., can solve the problems of inability to guarantee the adhesion of tape to the surface of film material, leakage can occur at the pigtail end of the bag, and the mass leaving the bag can contaminate the environment, so as to prevent leakage from the packaging bag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

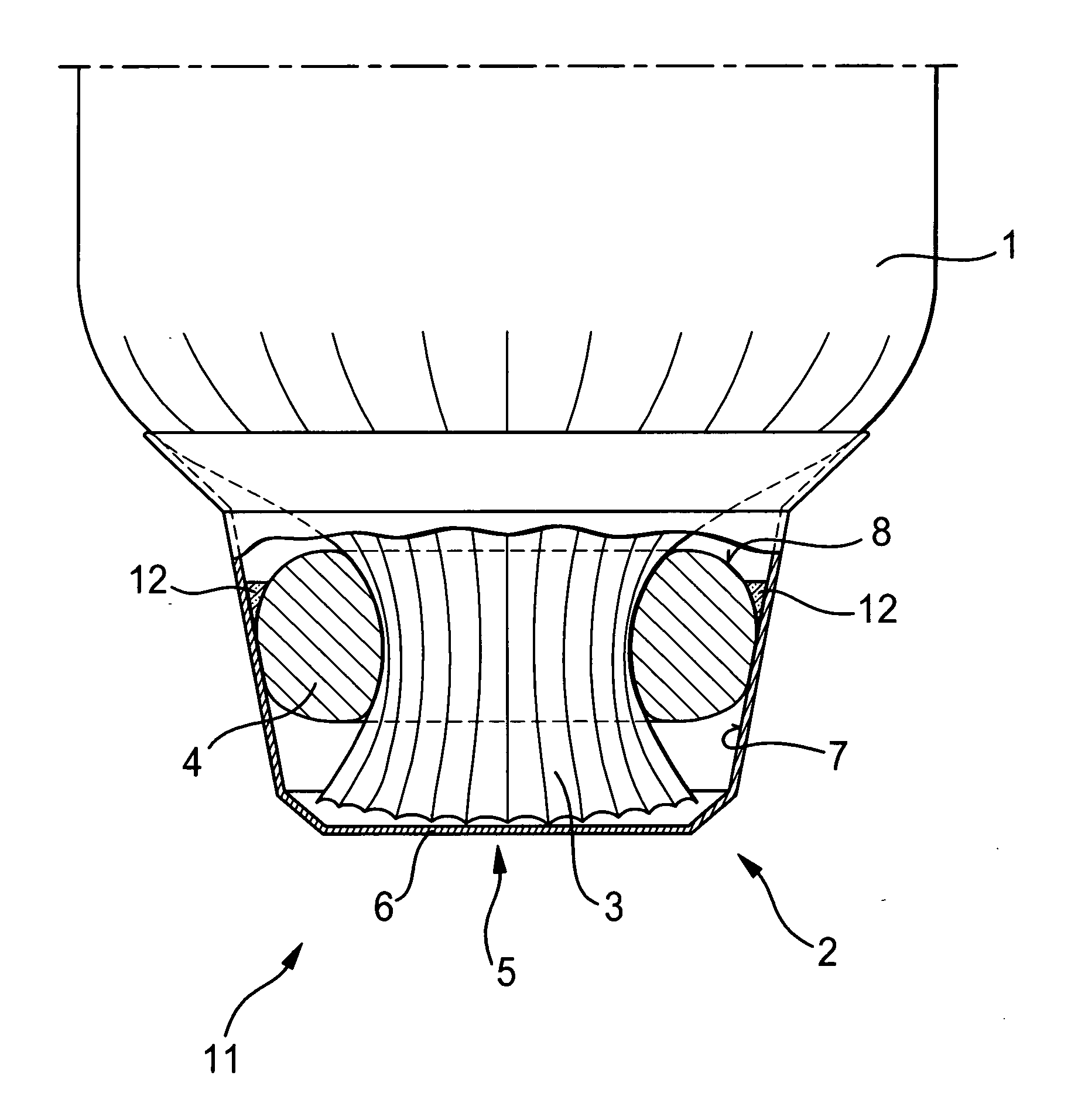

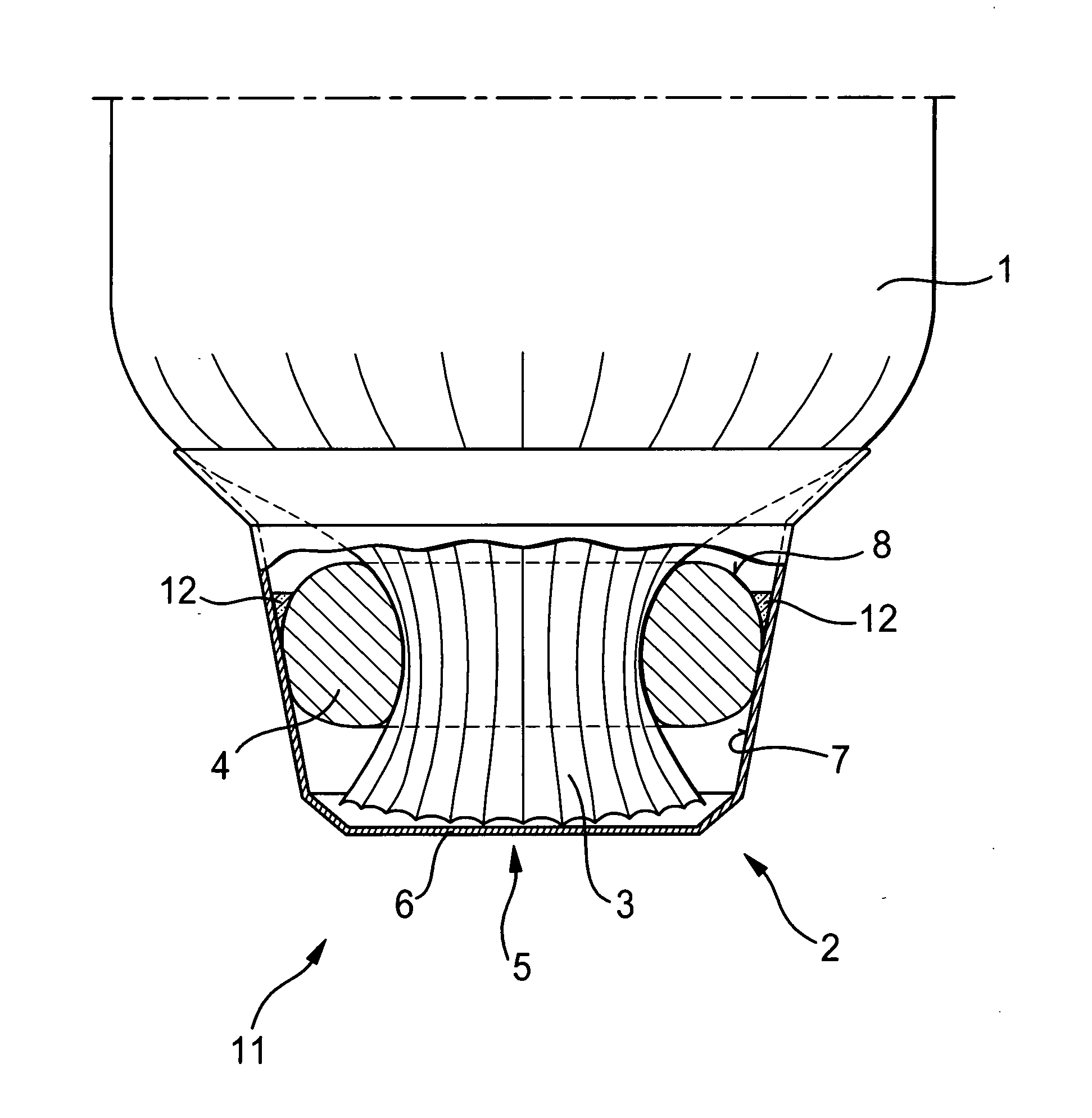

[0018] The closing device 11 according to the present invention is arranged at an end-of a closing section 2 of a flexible or pouch bag 1 that is shown only partially and forms a packaging for a filler material. The bag 1 is formed of a film material. The end-side closing section 2 extends up to a pigtail end 3 that is closed by a clamp 4 which surrounds the pigtail end 3. The free end 5 of the pigtail end 3 is surrounded by a cap 6 that is secured on the clamp 4 with an adhesive 12. The adhesive 12 is a cyanacrylate glue.

[0019] The adhesive 12 is selectively applied, at several points, to the inner surface 7 of the cap 6, and then the cap 6 is pressed over the clamp 4 by being rotated about the pigtail end 3.

[0020] According to an alternative embodiment, the adhesive 12 is applied over the circumference of the outer surface 8 of the clamp 4, and the cap 6 is pressed over the clamp 4 by being rotated about the pigtail end.

[0021] Though the present invention was shown and describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com