Self-locking osteosynthesis device

a self-locking, osteotomy technology, applied in the field of self-locking osteosynthesis or osteotomy devices, can solve the problems of difficult practical creation of a device of this type, no possibility to choose the orientation of the screws, and the thickness of the plates, so as to achieve the effect of significantly reducing the dimension of the plates that can be used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

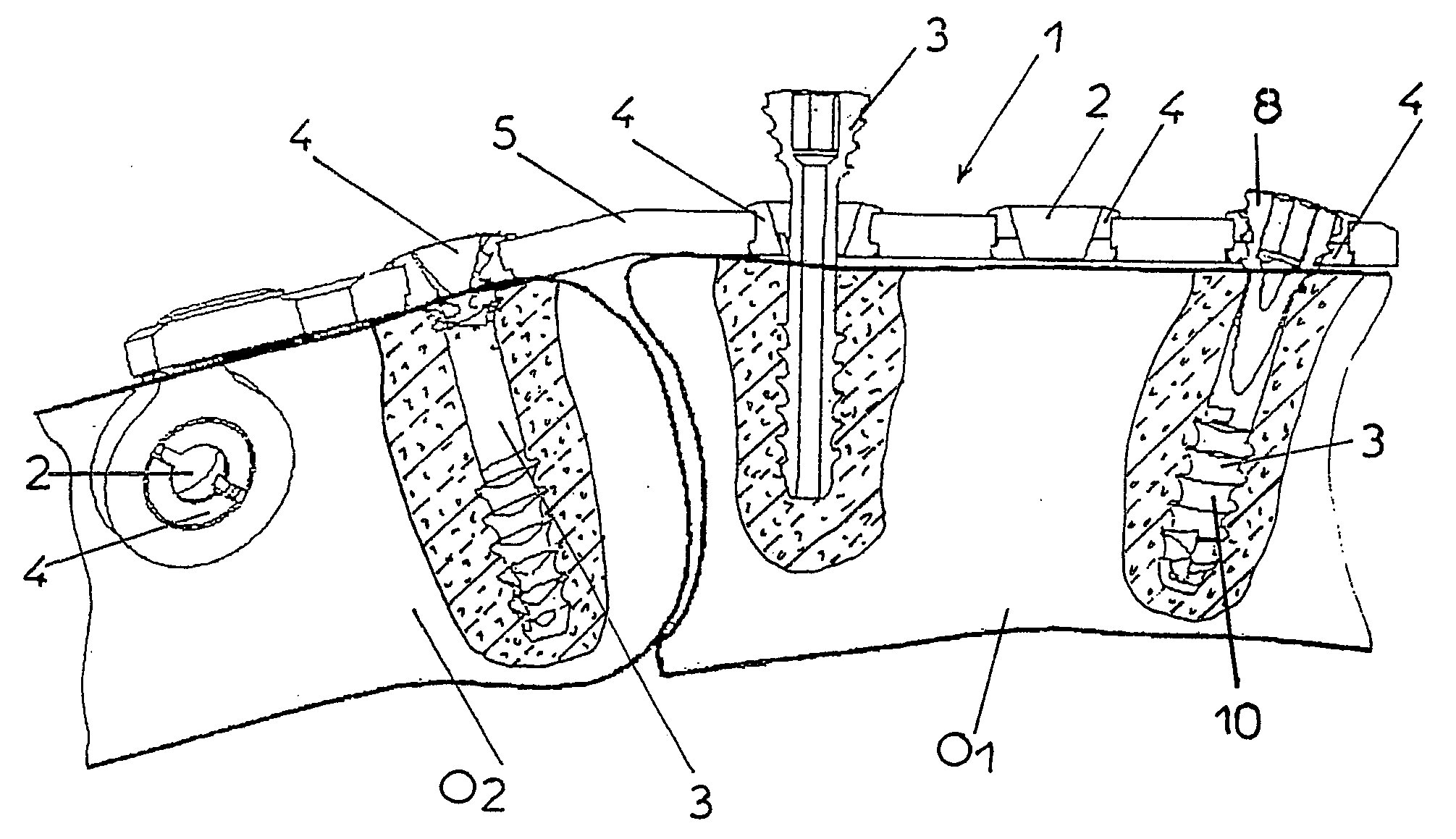

[0034] Reference is made to the drawings in order to describe an embodiment example that is of interest, though in no way restrictive, of the self-locking osteosynthesis device according to the invention.

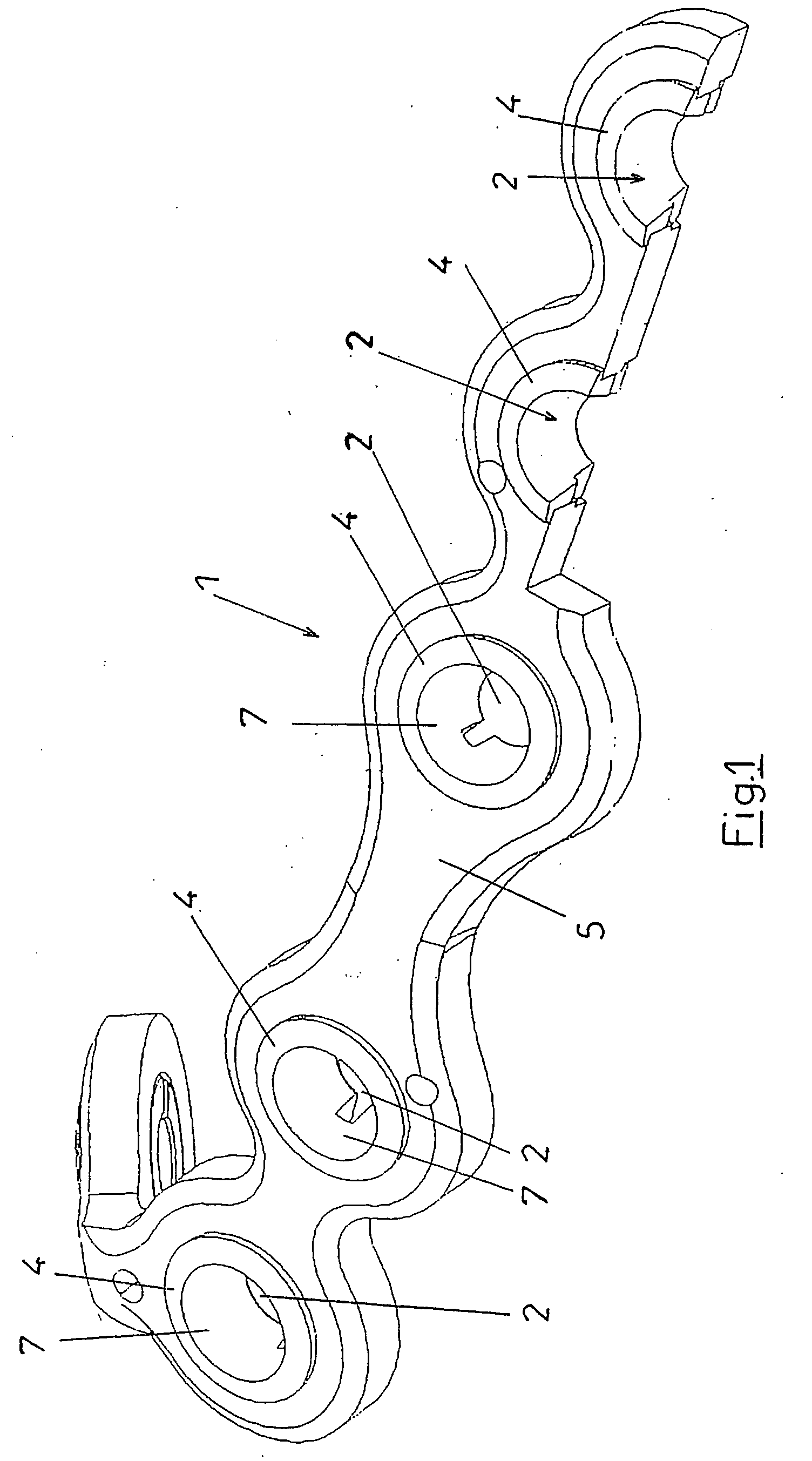

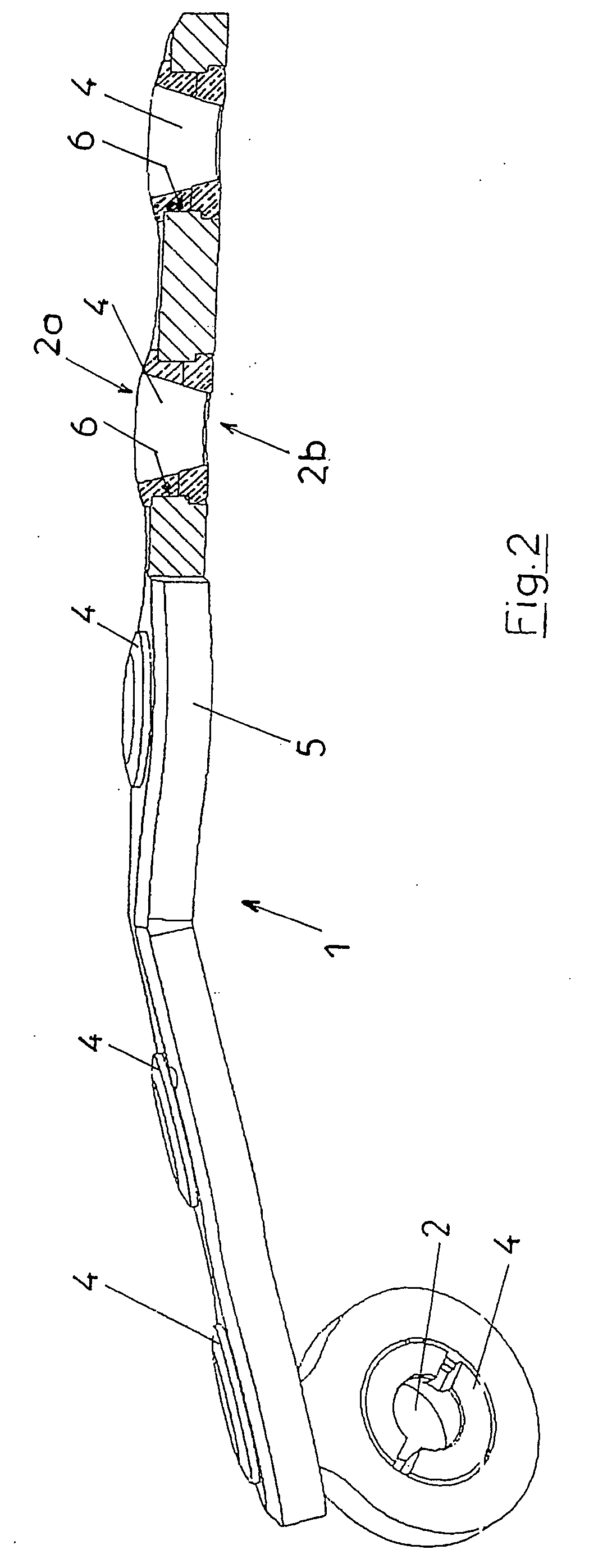

[0035] This device comprises a plate 1 equipped with passage holes 2 and fixation screws 3.

[0036] According to the invention, the plate 1 is made, at least in the defining zones of the passage holes 2 of the screws 3, of a material 4 that has the mechanical properties that allow a self-locking of the periphery of these holes using tapping screws for the fixation of the plate on the bone material.

[0037] The plate 1 can have any shape designed for the cases to be treated with reduction of fractures or restorative surgery; the shape shown in FIG. 1 is thus only a possible example of the shape, and the same applies for the placement of the holes 2 in the plate.

[0038] In a preferred manner, the plate 1 is made up of a composite plate whose peripheries 4 of the holes 2 are made of a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com