Dual catalyst on a single support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Catalyst A

[0155] In a glovebox, 1.95 g of silica-supported MAO prepared above was slurried in 15 mL of toluene. Separately, 35 mg of catalyst component 1 was dissolved in 20 mL of toluene, and 12 mg of (tBu3PN)(n-butyl indenyl)TiCl2 was dissolved in 20 mL of toluene. Both catalyst solutions were added simultaneously to the silica slurry. After 1 hour of stirring, the slurry was filtered, yielding a clear filtrate. The solid component was washed twice with toluene, and once with heptane. The final product was dried in vacuo to 300 mtorr (40 Pa) and stored under nitrogen until use.

[0156] A 2 L stirred autoclave reactor was heated at 100° C. for 1 hour and thoroughly purged with nitrogen. 160 g of NaCl predried in an oven at 160° C. for at least a week was added in the reactor which was subsequently pressure purged three times with nitrogen and twice with ethylene at 100° C. The reactor was then cooled to 90° C. and an aliquot of 25 weight % triisobuty...

example 2

Preparation of Catalyst B

[0158] In a glovebox, 1.95 grams of silica-supported MAO prepared above was slurried in 15 mL of toluene. Separately, 26 mg of catalyst component 1 was dissolved in 20 mL of toluene, and 21 mg of (tBu3PN)(C6F5CH2Cp)TiCl2 was dissolved in 20 mL of toluene. Both catalyst solutions were added simultaneously to the silica slurry. After one hour of stirring, the slurry was filtered, yielding a clear filtrate. The solid component was washed twice with toluene, and once with heptane. The final product was dried in vacuo to 300 mTorr and stored under nitrogen until use.

[0159] The polymerization was the same as Example 1, except that 26.7 mg of Catalyst B was used for polymerization, producing 46.8 g of polymer.

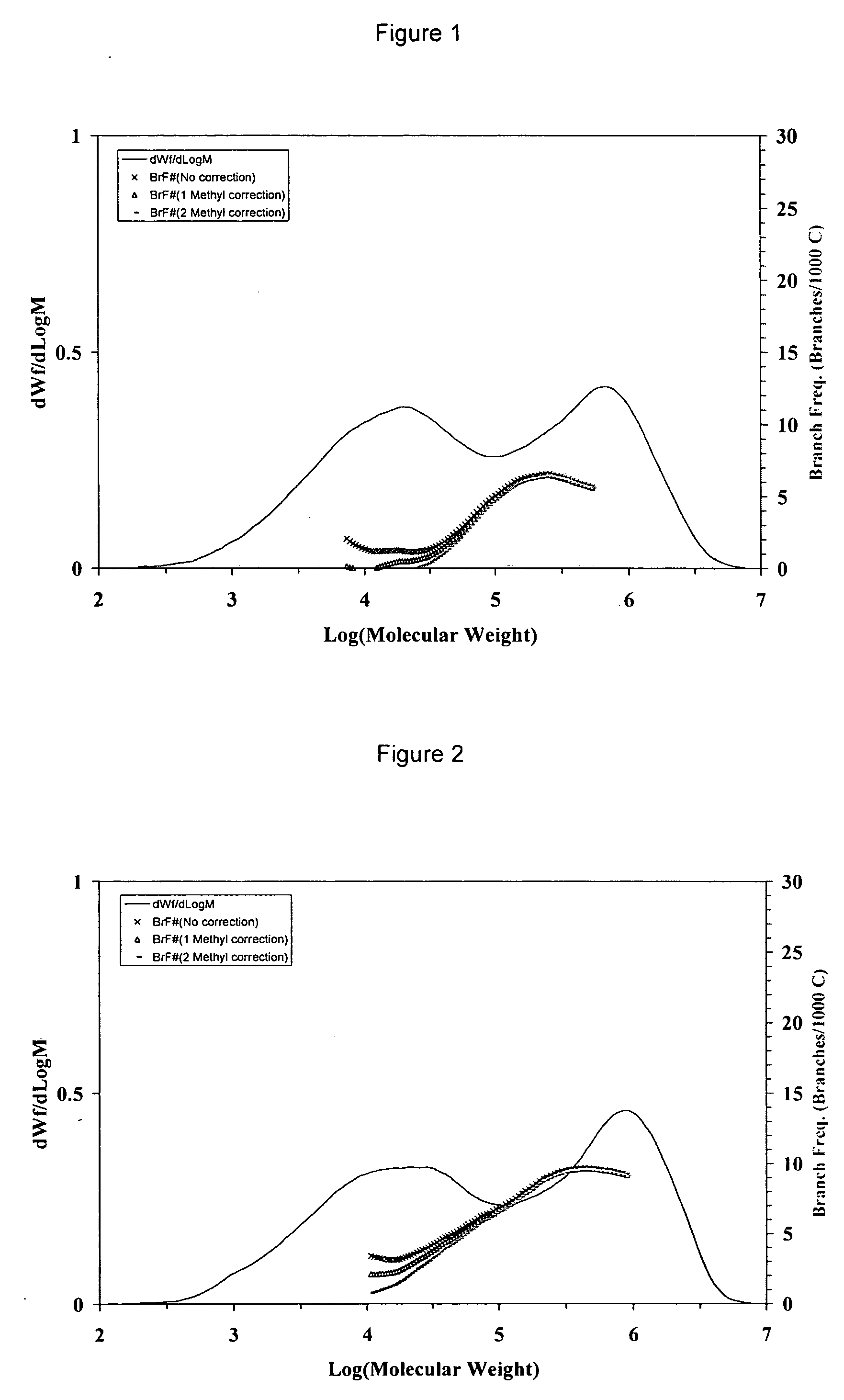

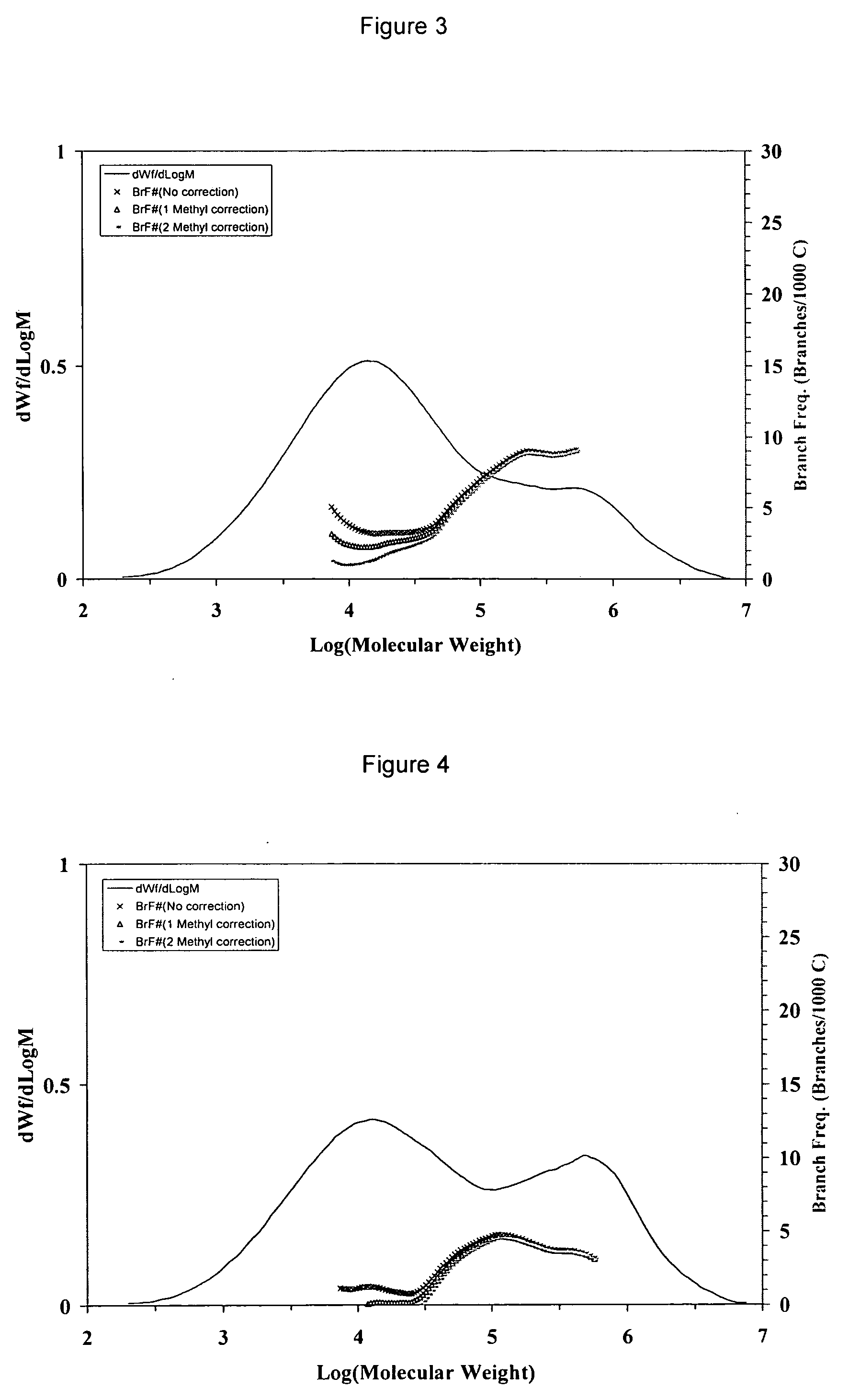

[0160] As seen in FIG. 2, the GPC-FTIR plot shows that the polymer is bimodal with most of comonomer incorporation in the high molecular weight fraction.

example 3

Preparation of Catalyst C

[0161] In a glovebox, 2.92 grams of silica-supported MAO prepared above was slurried in 30 mL of toluene. Separately, 63.0 mg of catalyst component 1 was dissolved in 25 mL of toluene, and 13.3 mg of (tBU3PN)(C6F5)(n-Bu)CpTiCl2 was dissolved in 10 mL of toluene. Both catalyst solutions were added simultaneously to the silica slurry. After one hour of stirring, the slurry was filtered, yielding a clear filtrate. The solid component was washed twice with toluene, and once with heptane. The final product was dried in vacuo to 300 mTorr (40 102 Pa) and stored under nitrogen until use.

[0162] The polymerization was the same as Example 1, except that 20.9 mg of Catalyst C was used for polymerization, producing 45.8 g of polymer

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com