Valve for liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

DETAILED DESCRIPTION OF THE DRAWINGS

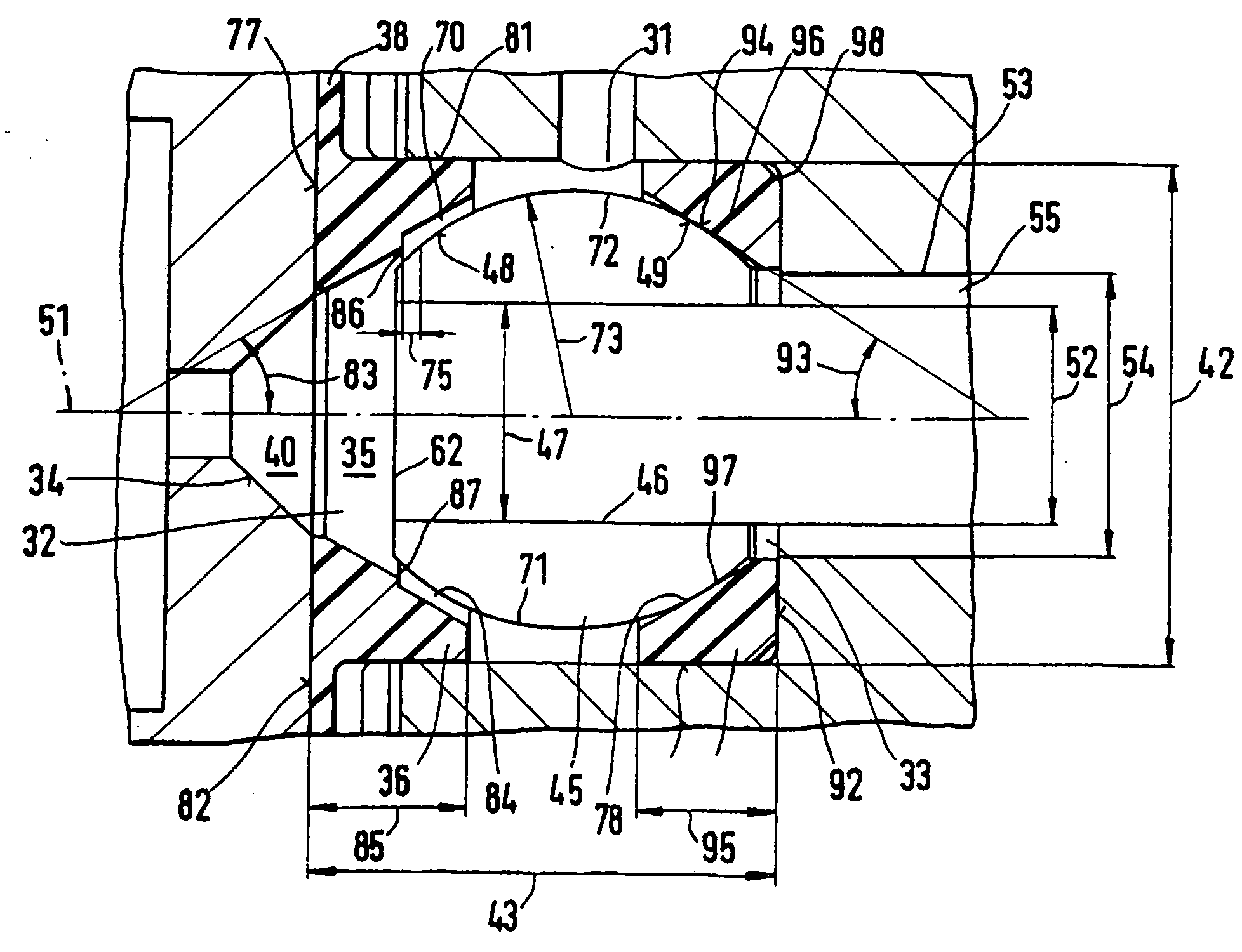

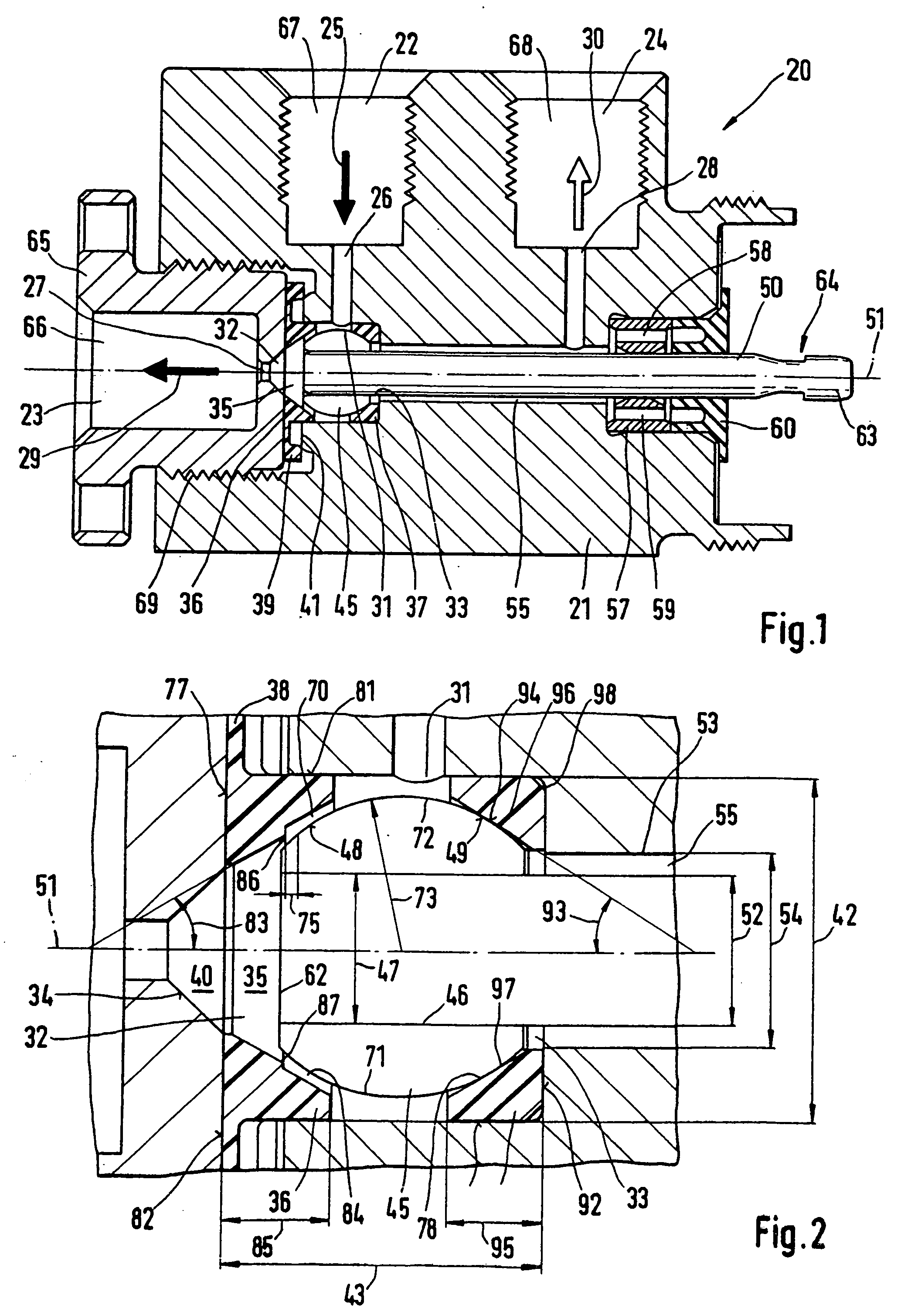

[0028] The valve 20 in FIG. 1 is designed as a three / two-way valve and has a valve body 21 with external inlet 22 and a primary external outlet 23 and secondary external outlet 24. Inlet 22 has a connecting hole 67 to connect connecting lines (not shown) and ends in the cylindrical inlet channel 26. Channel 26 ends in interior inlet 31 that is assigned to the switching chamber 35. The switching chamber 35 also has a primary interior outlet 32 and secondary interior outlet 33 that is opposite the primary interior outlet 32. The interior outlets 32, 33 are symmetrical to the actuation, i.e., longitudinal axis 51 of actuator 50 and are on opposite sides of the inlet 31 at an angle of 90° to the interior inlet.

[0029] In the switching chamber 35 is first annular valve seat 36 assigned to the primary interior outlet 32 and the second annular valve seat 37 assigned to the secondary interior outlet 33. Also in the switching chamber 35 is the switchable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com