Erosion control barrier

a technology of erosion control and barrier, applied in excavations, construction, marine site engineering, etc., can solve the problems of reducing the ability of fiber rolls to direct fluid flow in a controlled manner, preventing the use of silt fences alone, and reducing the acceptance of applicants' candor, so as to reduce soil erosion and improve barriers. , the effect of disclosing the applicant's duty of candor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

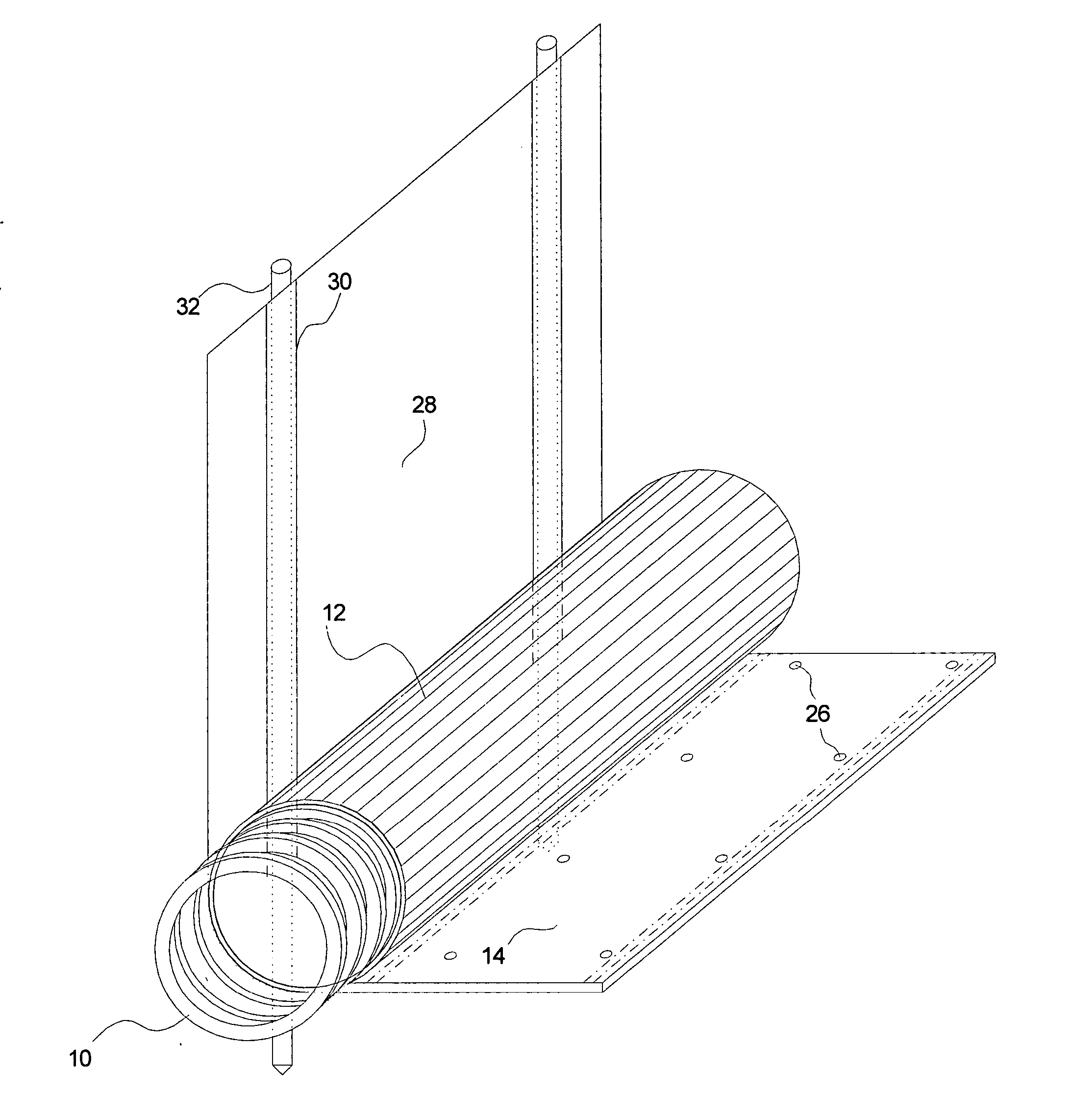

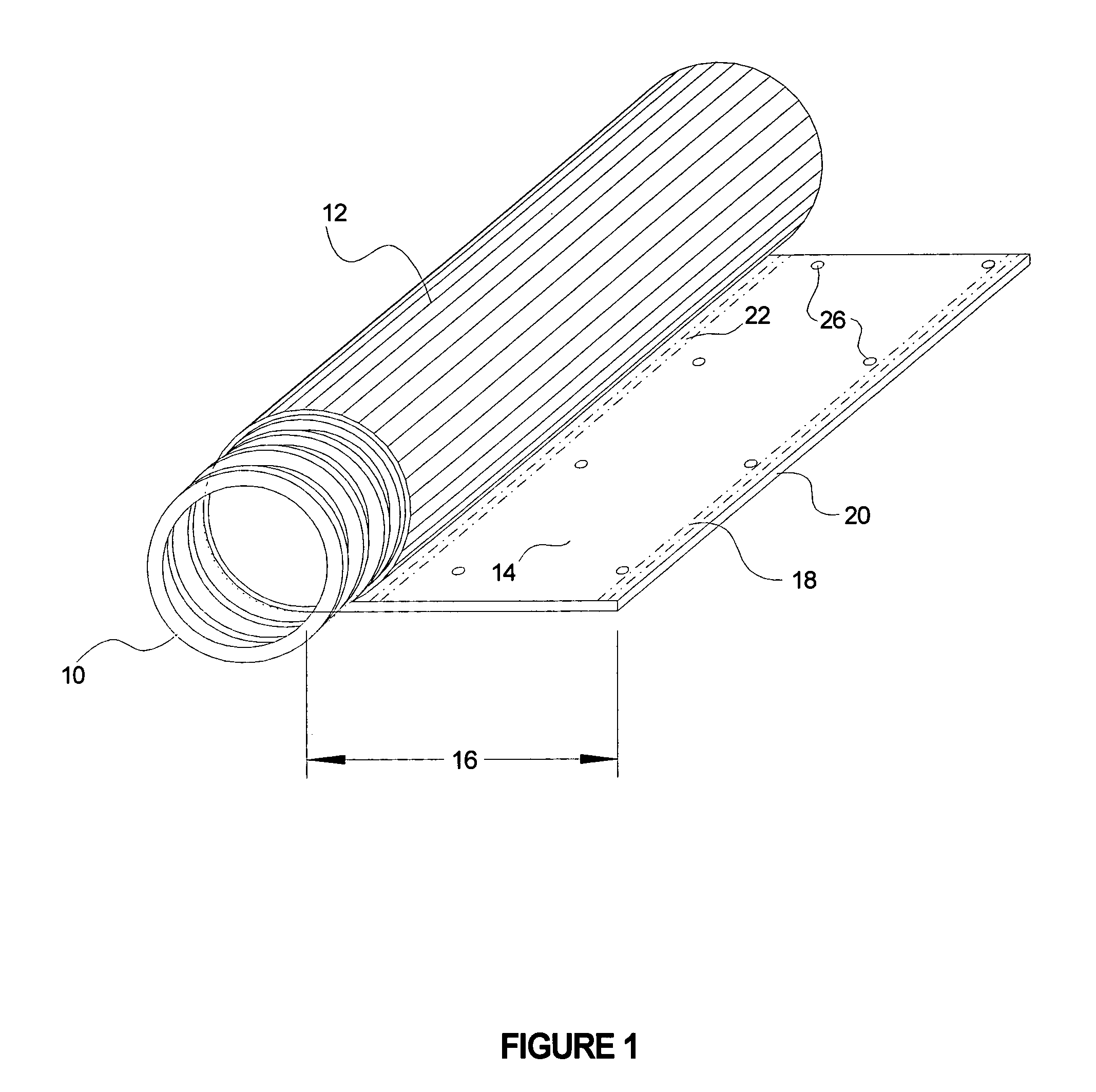

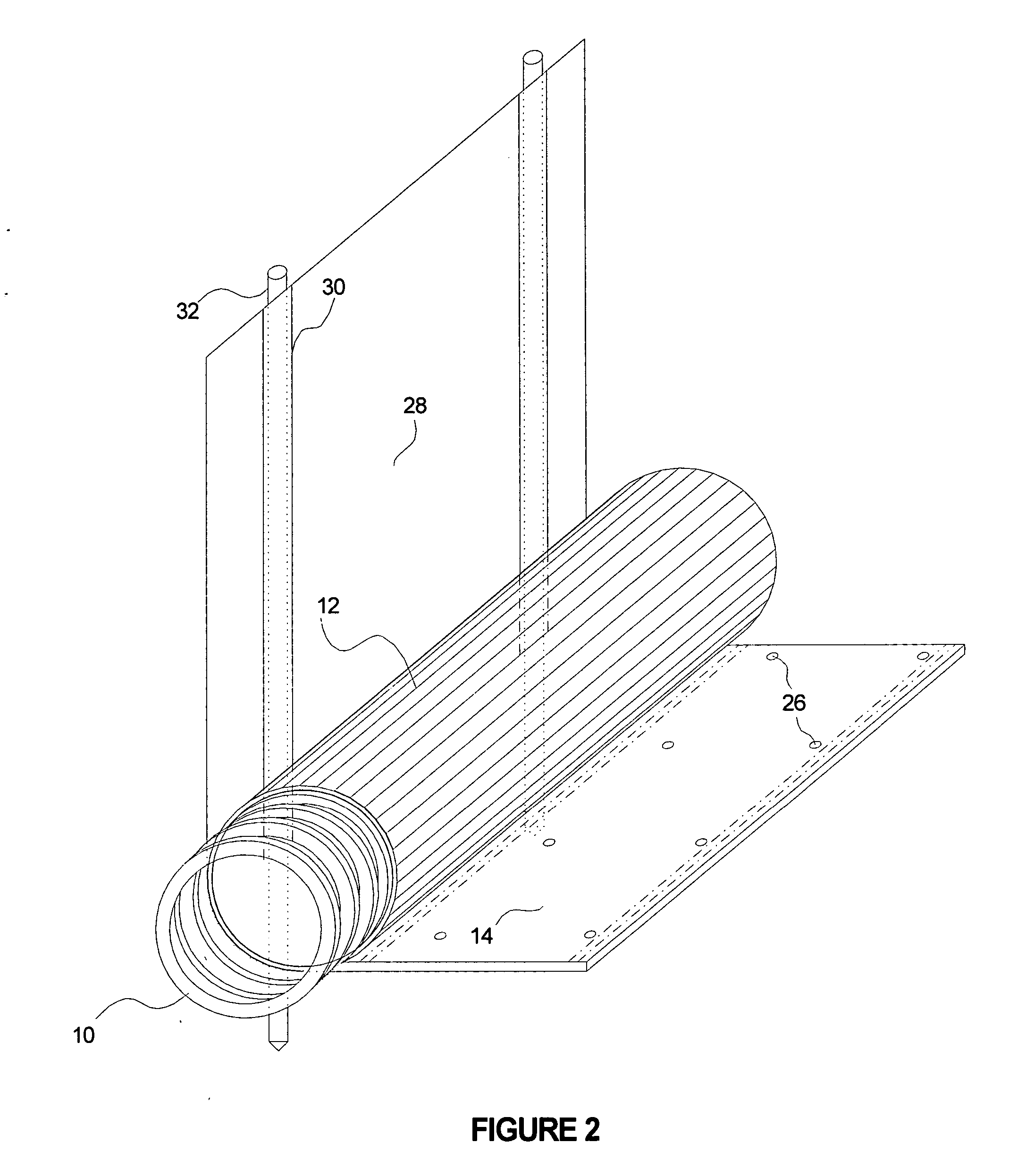

[0025] Referring to FIGS. 1 through 6, wherein like reference numerals refer to like components in the various views, there is illustrated therein a new and improved erosion control barrier. The erosion control barrier of the present invention is adapted for use in controlling sedimentation and debris flow, especially in connection with construction site and hillside runoff. In its most essential aspect, the apparatus includes a hollow core member covered with an outer filter member incorporating a longitudinal apron which serves several purposes: It provides means to secure the hollow core member to the ground; it directs fluid flow to the core member; and it covers the ground adjacent the core member to prevent soil erosion around and beneath the core member. The present invention is particularly useful in controlling erosion resulting from sedimentation and debris flow on slopes at construction sites and other areas where soil erosion poses environmental issues.

[0026] Referring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com