Optical encoder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

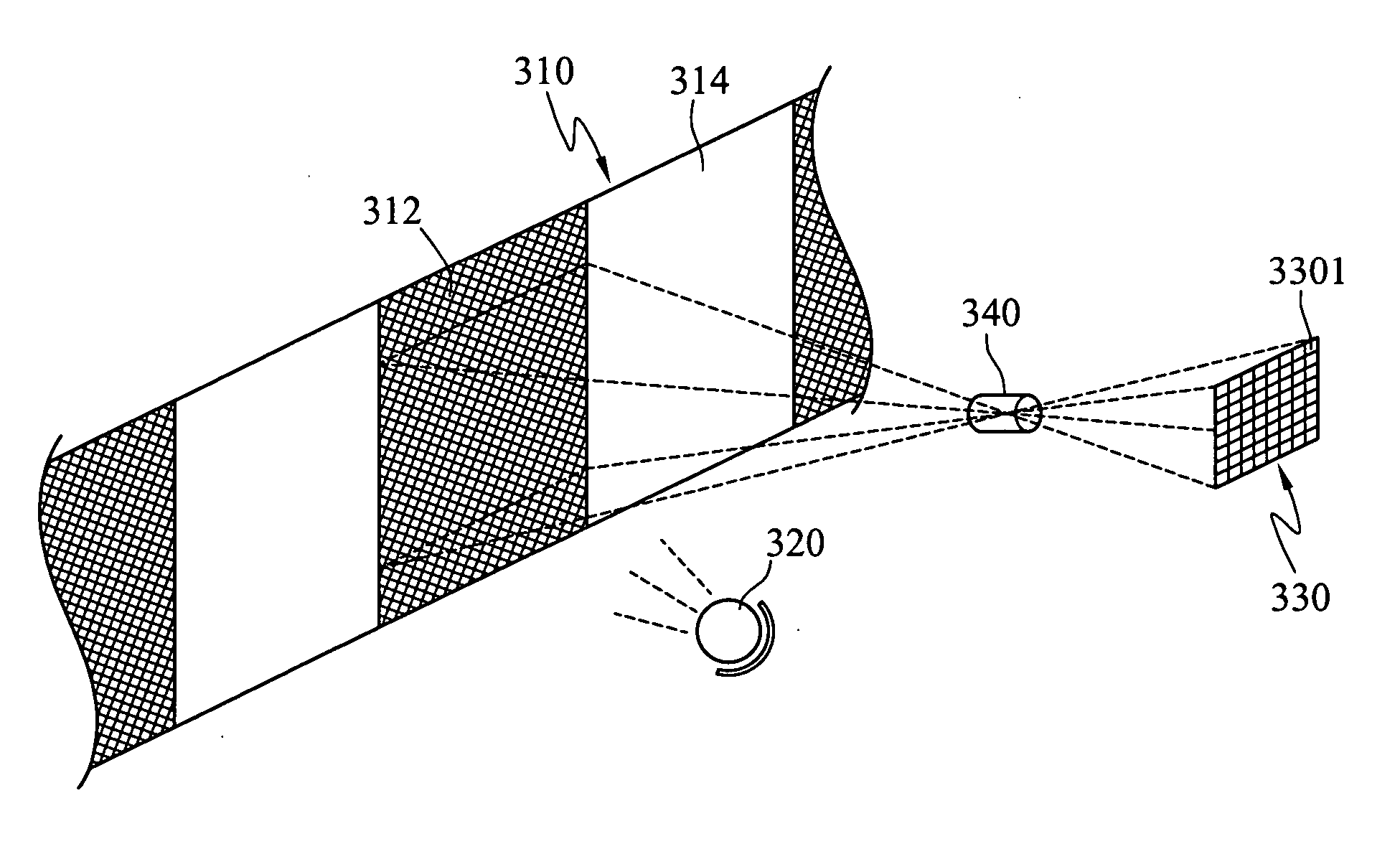

[0031] With reference to FIG. 4, an embodiment of the optical detector comprises: a code strip 310, a light source 320, a light sensing element 330, and a first lens set 340.

[0032] The code strip 310 is driven by a wheel (not shown) in response to the rotating device. It has reflective regions 312 and non-reflective regions 314 which are staggered. The code strip 310 is such as a code wheel or an optical scale.

[0033] The light source 320 emits light to illuminate the reflective regions 312 on the code strip 310. The light source 320 is such as an LED illuminator.

[0034] The light sensing element 330 disposed on the same side of the code strip 310 as the light source 320 receives the modulated light beam reflected by the reflective regions 312 and converts it into an electrical signal, thereby producing a binary identification code to determine the location of the rotating device for controlling the speed and stroke of the rotating device.

[0035] The light detecting element 330 has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com