Reciprocating seal

a technology of reciprocating seals and sealing plates, applied in the direction of engine seals, springs/dampers, shock absorbers, etc., can solve the problems of difficult to improve the characteristics of frictional force, and achieve the effect of preventing an increase in frictional for

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereafter, the best mode of this invention will be described as an example in detail with reference to the drawings. However, as for the size, material, shape, and relative arrangement of constituent parts described in this embodiment, it is not intended to limit the scope of this invention only to these unless otherwise specified.

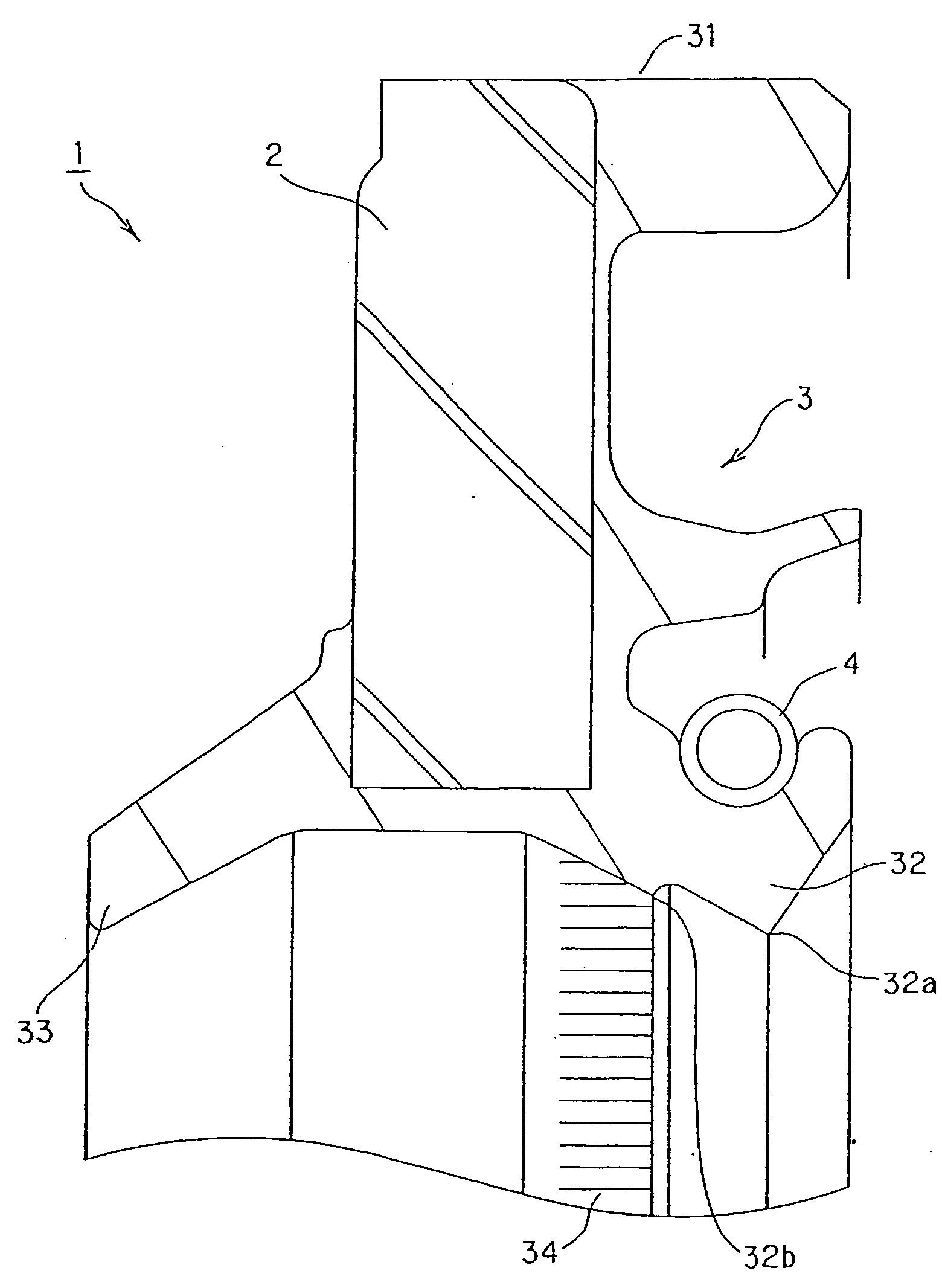

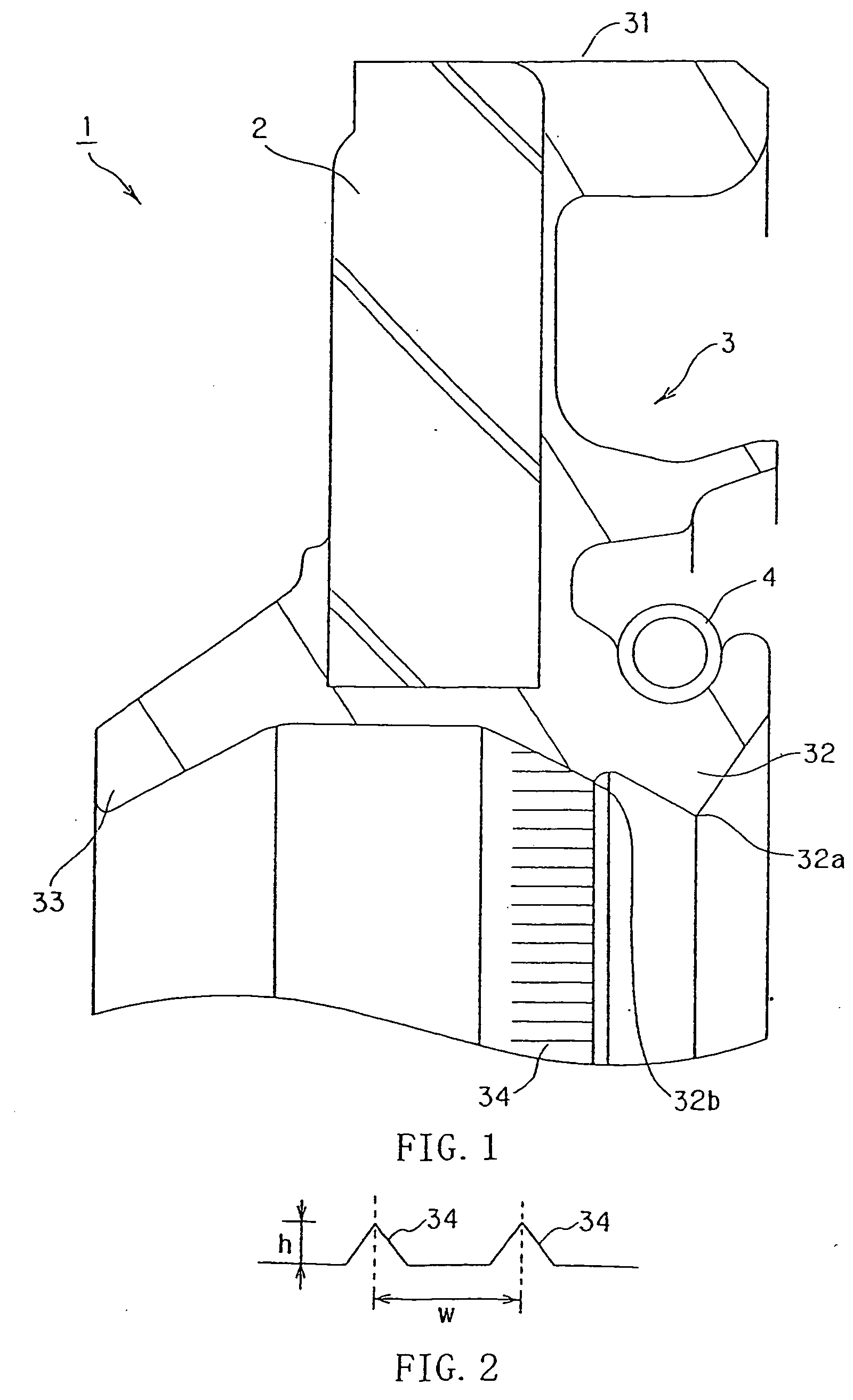

[0036] A reciprocating seal according to the invention will be described with reference to FIG. 1.

[0037]FIG. 1 is a schematic sectional view of a reciprocating seal according to the embodiment of the invention.

[0038] The reciprocating seal 1 according to the embodiment of the invention can be suitably used for a shock absorber mounted in an automobile and the like.

[0039] Further, the reciprocating seal 1 according to the embodiment of the invention is arranged in an annular space between a shaft (not shown) and the inner periphery of a housing (shaft hole made in the housing, in more detail), which move relatively to each other in the direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com