Naphtha desulfurization process

a technology of desulfurization process and naphtha, which is applied in the direction of physical/chemical process catalyst, hydrocarbon oil treatment product, hydrocarbon oil treatment, etc., can solve the problems of further loss of desirable molecules contributing to high octane, increased production cost of high octane fuels, and loss of molecules contributing to desirable octan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

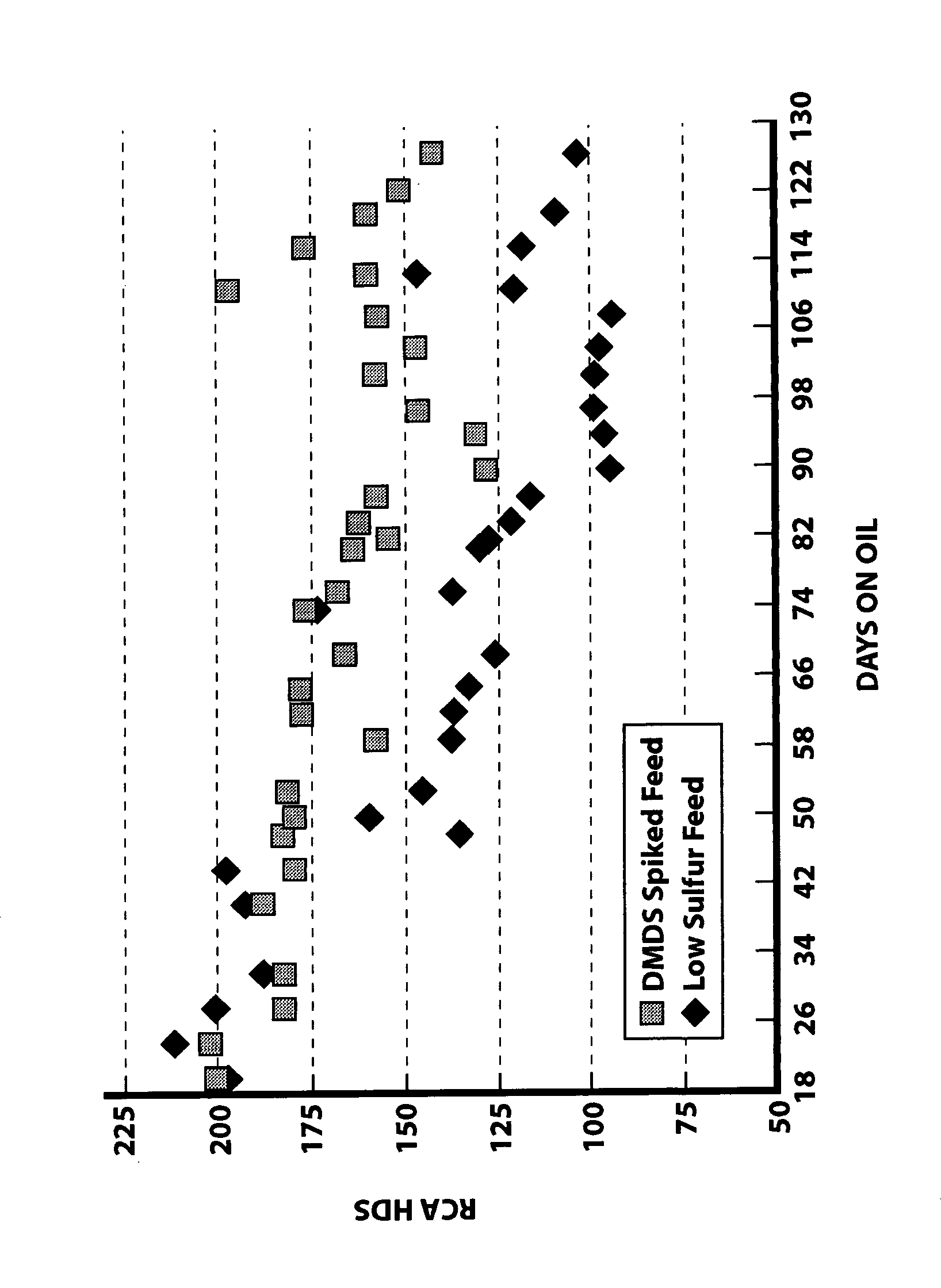

[0036] A SCANfining® pilot unit was loaded with catalyst RT-225 which is commercially available from Exxon Mobil Coporation. The RT-225 catalyst contains 4.5 wt. % MoO3 and 1.2 wt. % CoO, on an alumina support. The catalyst was in a quadralobe shape and had a catalyst size of 1.3 mm. After a preliminary drying at 399° C. (750° F.) for 3 hours, the catalyst was loaded in a pilot unit and further dried at 371° C. (700° F.) for 6 hours. The catalyst was then sulfided using a 10 vol. % H2S in H2 mixture at an initial temperature of 93° C. (200° F.) and a final temperature of 343° C. (650° F.).

[0037] The catalyst was then activated using a straight run naphtha and a heavy cat naphtha used for catalyst break-in. Two feeds were then prepared for the low sulfur and high sulfur runs. The low sulfur feed was a naphtha blend having a total sulfur content of about 30 wppm, based on feed. The high sulfur feed had a total sulfur content of about 550 wppm and was prepared by spiking a low sulfur ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size diameter | aaaaa | aaaaa |

| pressures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com