Paperboard container with locking flaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

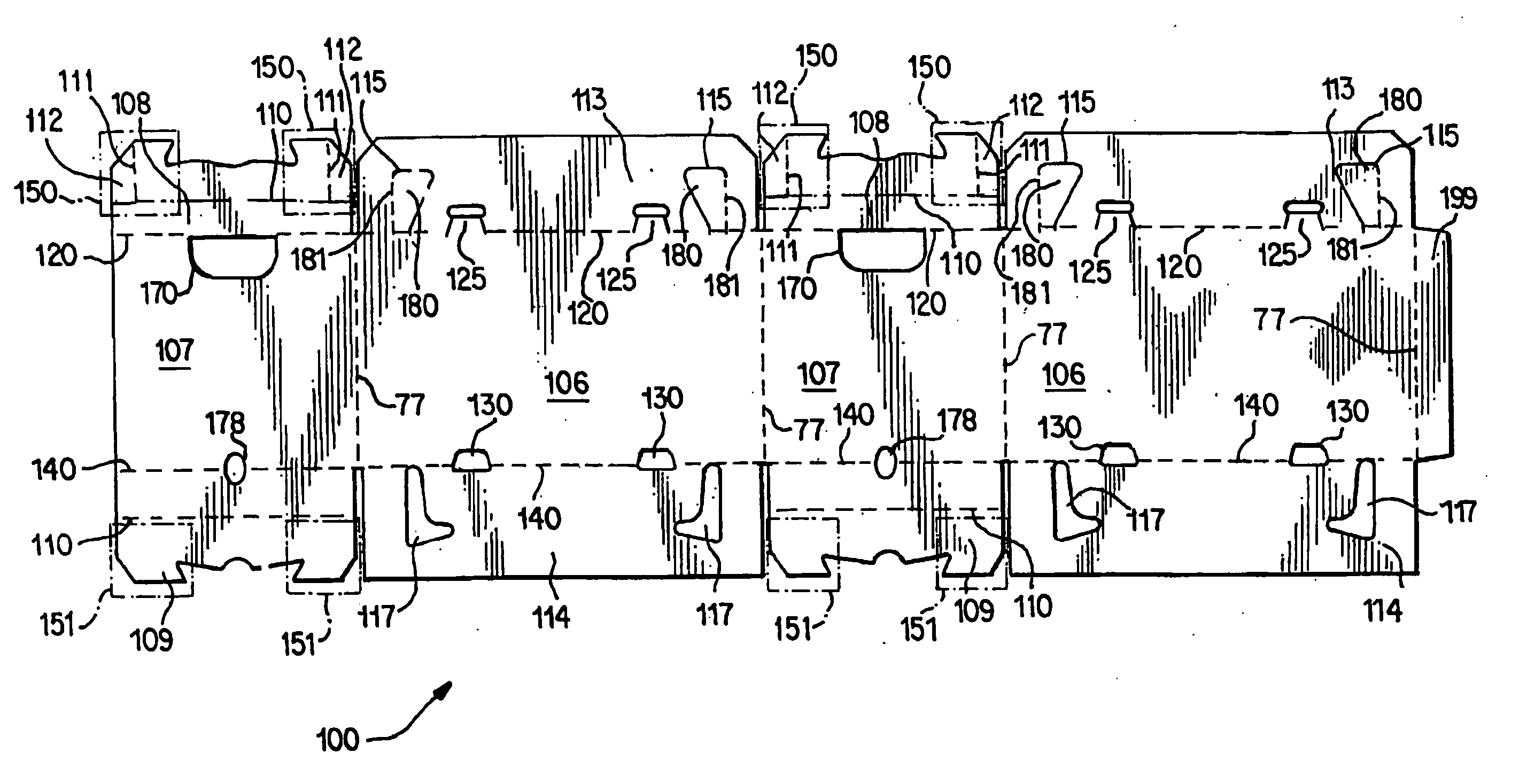

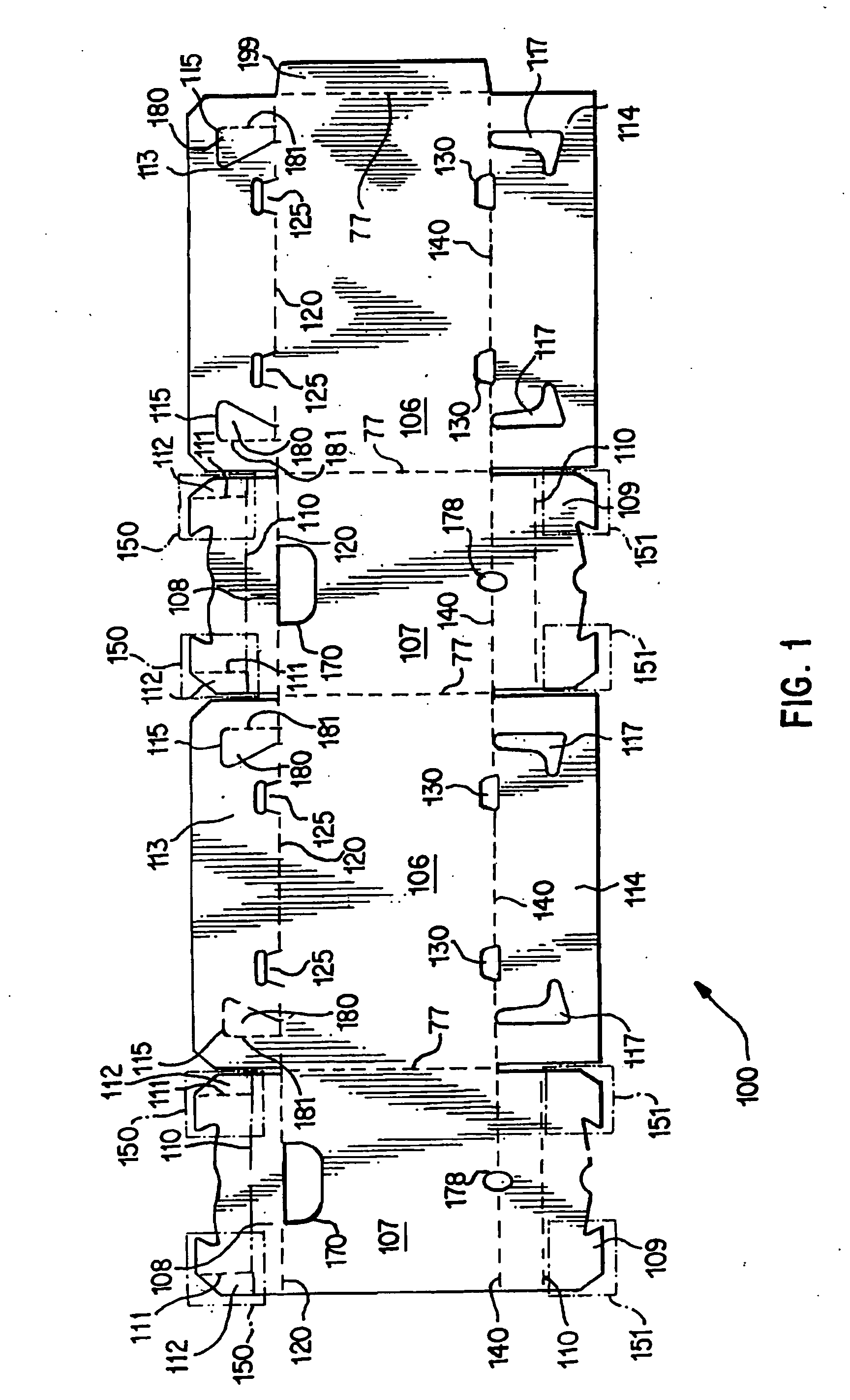

[0019]FIG. 1 illustrates a preferred construction of a knocked-down-flat (“KDF”) container blank 100. The blank 100 is used to construct a rectangular shaped container, although other configurations are possible, such as a cube shape. In a general construction, blank 100 includes two side wall panels 106 and two end wall panels 107 connected to four top flaps and four bottom flaps, the boundaries of which are formed by vertical fold lines 77 and horizontal fold lines 120, 140. For reference purposes, the fold lines are depicted as broken lines in FIG. 1. As used herein, a fold line may be a thin band of a weaken region of material. The thin band can be a specific area on a blank formed by conventional manufacturing methods in the paperboard art. Nevertheless, the fold line may be simply a predetermined area for folding along a part of the blank without a weaken area. The KDF container may be constructed by securing together the edges of a blank including the aforementioned panels.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com