Bellows Pump

a belt-type pump and belt-type technology, applied in the direction of pump components, positive displacement liquid engines, pulse equalisation, etc., can solve the problems of shortened pump life, loosened bolts may slip off, and pump failure to normally operate, etc., to reduce pump performance, shorten pump life, and increase sliding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

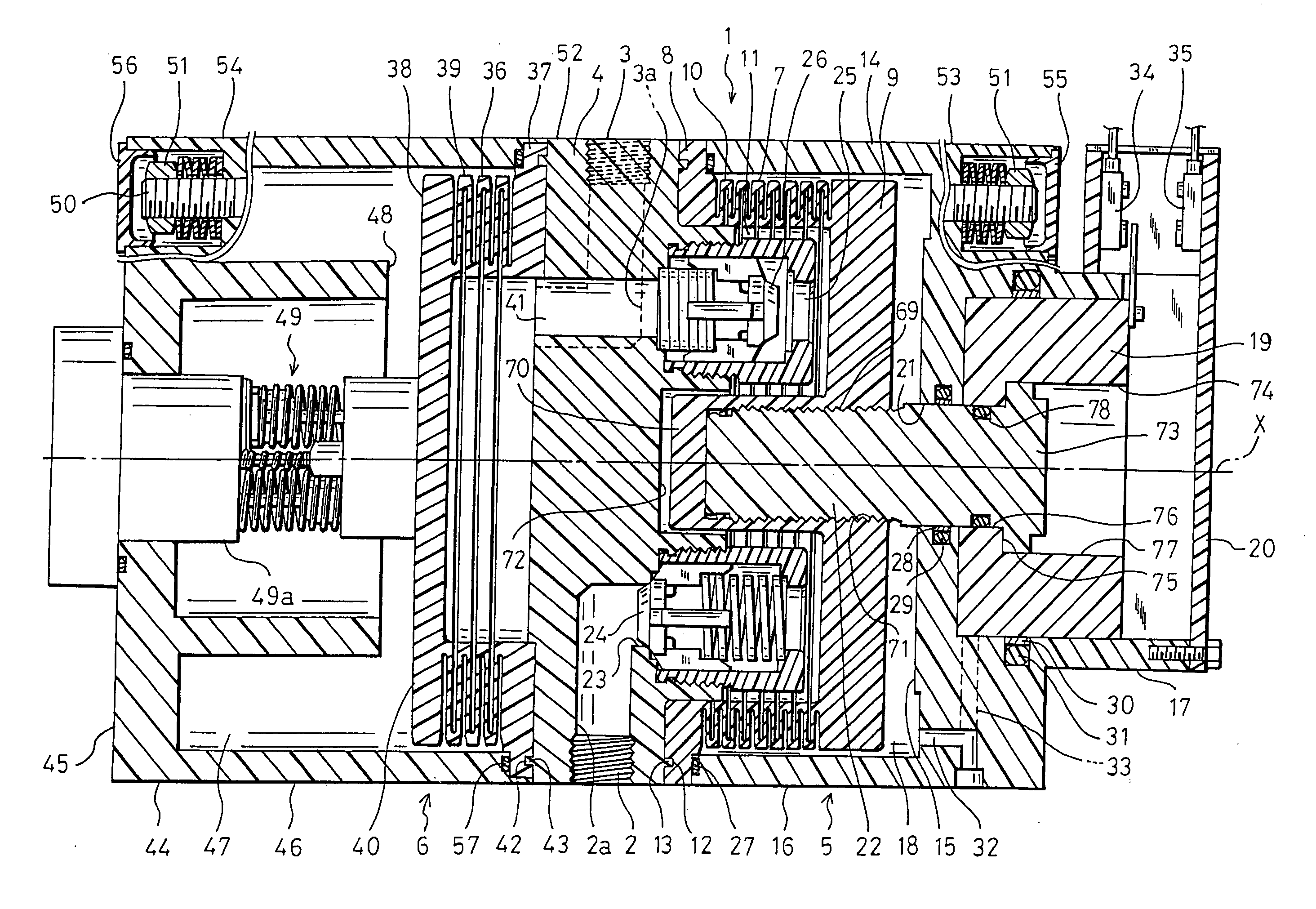

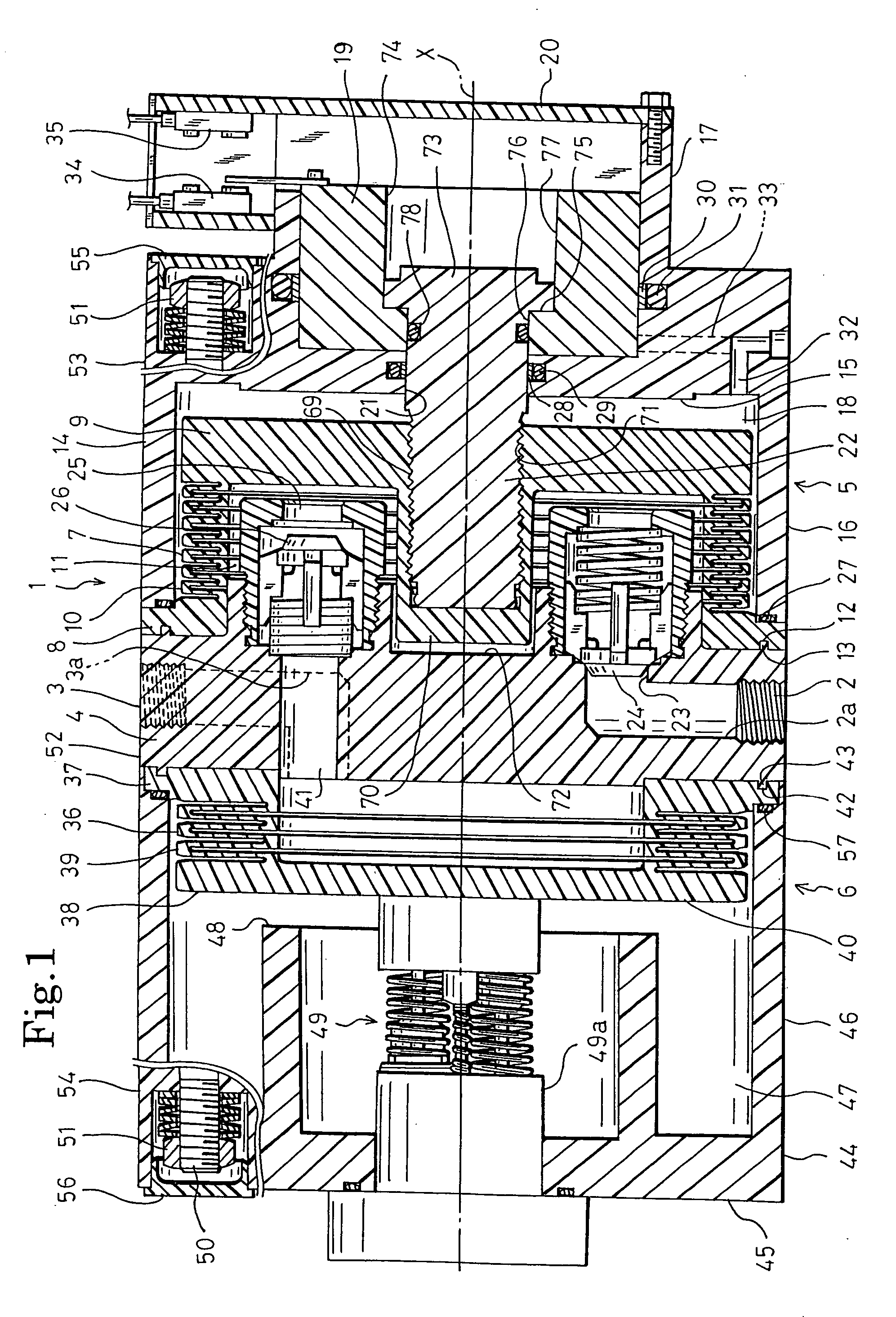

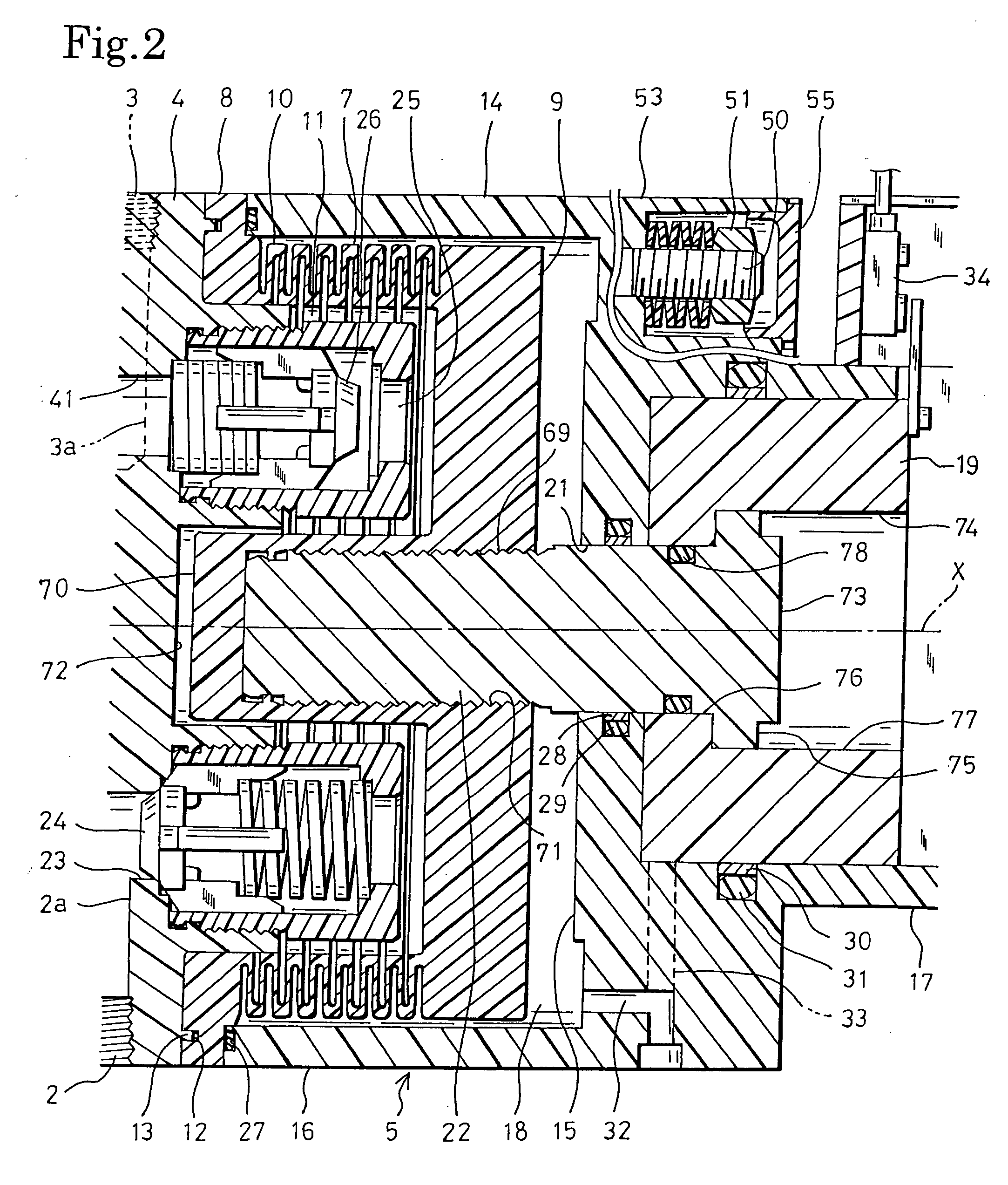

[0023] Hereinafter, embodiments of the invention will be described with reference to the accompanying drawings. FIG. 1 is a section view showing an internal structure of a bellows pump of the invention, and FIG. 2 is an enlarged view of a pump unit shown in FIG. 1. The bellows pump 1 is used as a pump for transporting a liquid such as a chemical liquid, a solvent, or pure water in, for example, a semiconductor manufacturing factory, and is configured by: a pump body 4 which is a substantially square plate-like pump head, and in which suction and discharge ports 2 and 3 for the transported liquid are formed; a pump unit 5 which is placed on one side (the right side in FIG. 1) of the pump body 4; and an accumulator unit 6 which is placed on the other side (the left side in FIG. 1) of the pump body 4.

[0024] A pump bellows 7 which can extend and contract in the axial direction (the lateral direction in FIG. 1) is placed in one side portion (the right side portion in FIG. 1) of the pump ...

second embodiment

[0037] The bellows pump 58 of the second embodiment is configured by the pump body 4, and a pair of pump units 5 which are placed on both sides (the right and left sides in FIG. 3) of the pump body 4 on the same axis X, respectively. In each of the pump units 5, the piston 19 is formed to have a diameter which is larger than the outer diameter of the first cylinder section 16 of the pump cylinder 14, and, in accordance with this, also the second cylinder section 17 is formed to have a diameter which is larger than the outer diameter of the first cylinder section 16. The pistons 19 of the pump units 5 are fastened together by plural metal tie rods 59 which are in parallel to the axis X, in the radially outer side of the first cylinder sections 16. In each of the tie rods 59, steps 59a, 59b are formed in end portions, respectively. The steps 59a, 59b enable the pistons 19 of the pump units 5 to be coupled together with maintaining a predetermined distance between the pistons. The inte...

third embodiment

[0049] As apparent from the above description, in summary, the bellows pump 67 of the third embodiment comprises: the pump body 4 in which suction and discharge ports 2 and 3 for the transported liquid are formed; and the pair of pump units 5 which are placed on both sides of the pump body 4, respectively. Each of the pump units 5 comprises: the bottomed cylindrical pump bellows 7 which is placed so that the open end portion 8 is joined to the pump body 4 in one side portion of the pump body 4 to internally form the pump chamber 11, and which can axially extend and contract; the pump cylinder 14 configured by the cylinder head portion 15 which is placed opposingly to the pump body 4 in the axially outside of the pump bellows 7, and the first cylinder section 16 which is projected on the same axis X as the pump bellows 7 from the cylinder head portion 15 toward the pump body 4 so as to internally accommodate the pump bellows 7, which is opposed in the open end portion to the pump bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com