Liquid-cooling heat dissipation assembly

a technology of heat dissipation assembly and liquid cooling, which is applied in the direction of indirect heat exchangers, domestic cooling devices, lighting and heating devices, etc. it can solve the problems of affecting the compact trend of computers, the bulky i>a /i> formed is bulky and difficult to assemble, and the expansion of the connection way of the construction and motherboard, so as to achieve speed up the heat exchange cycle and enhance the heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

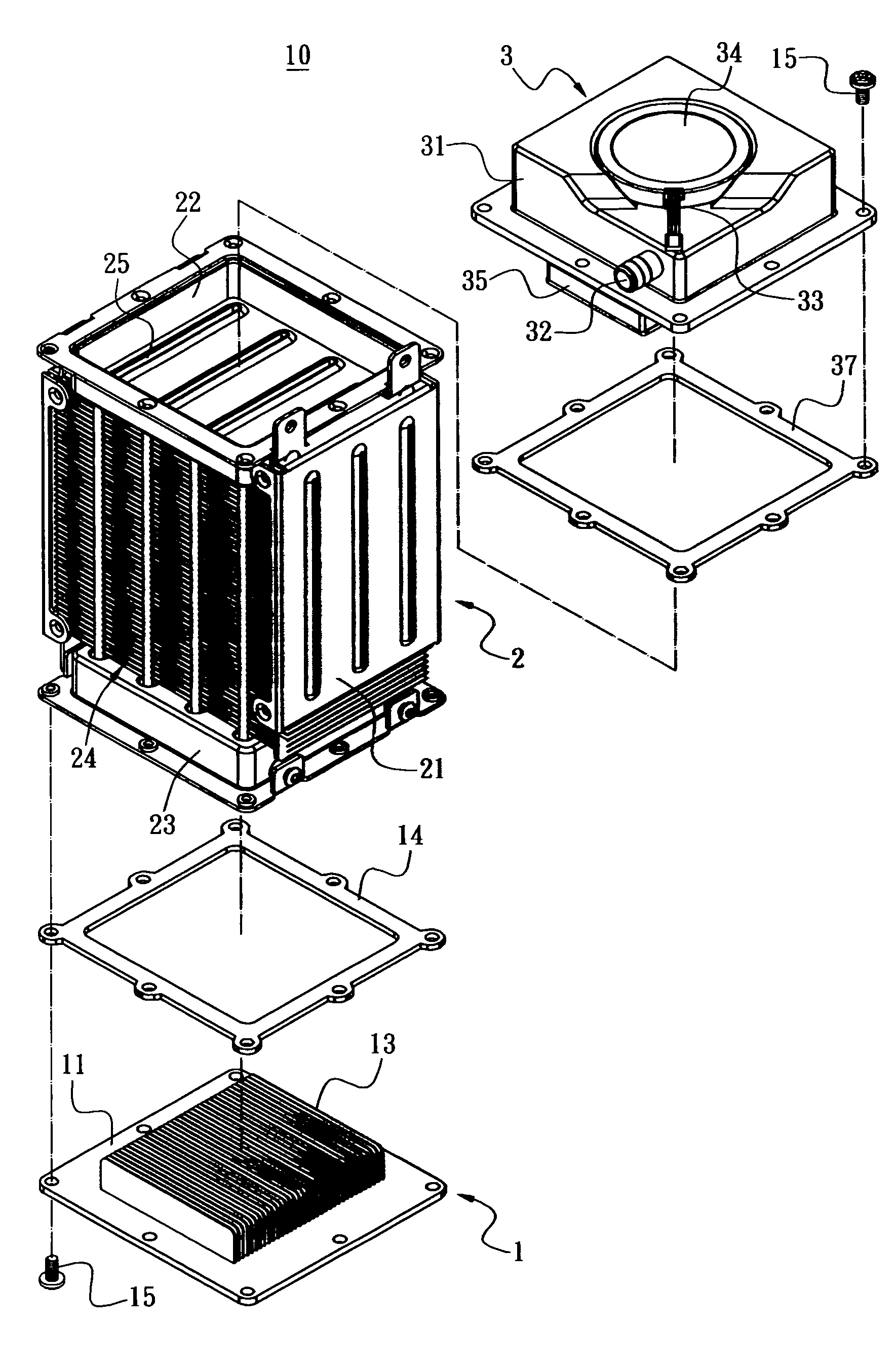

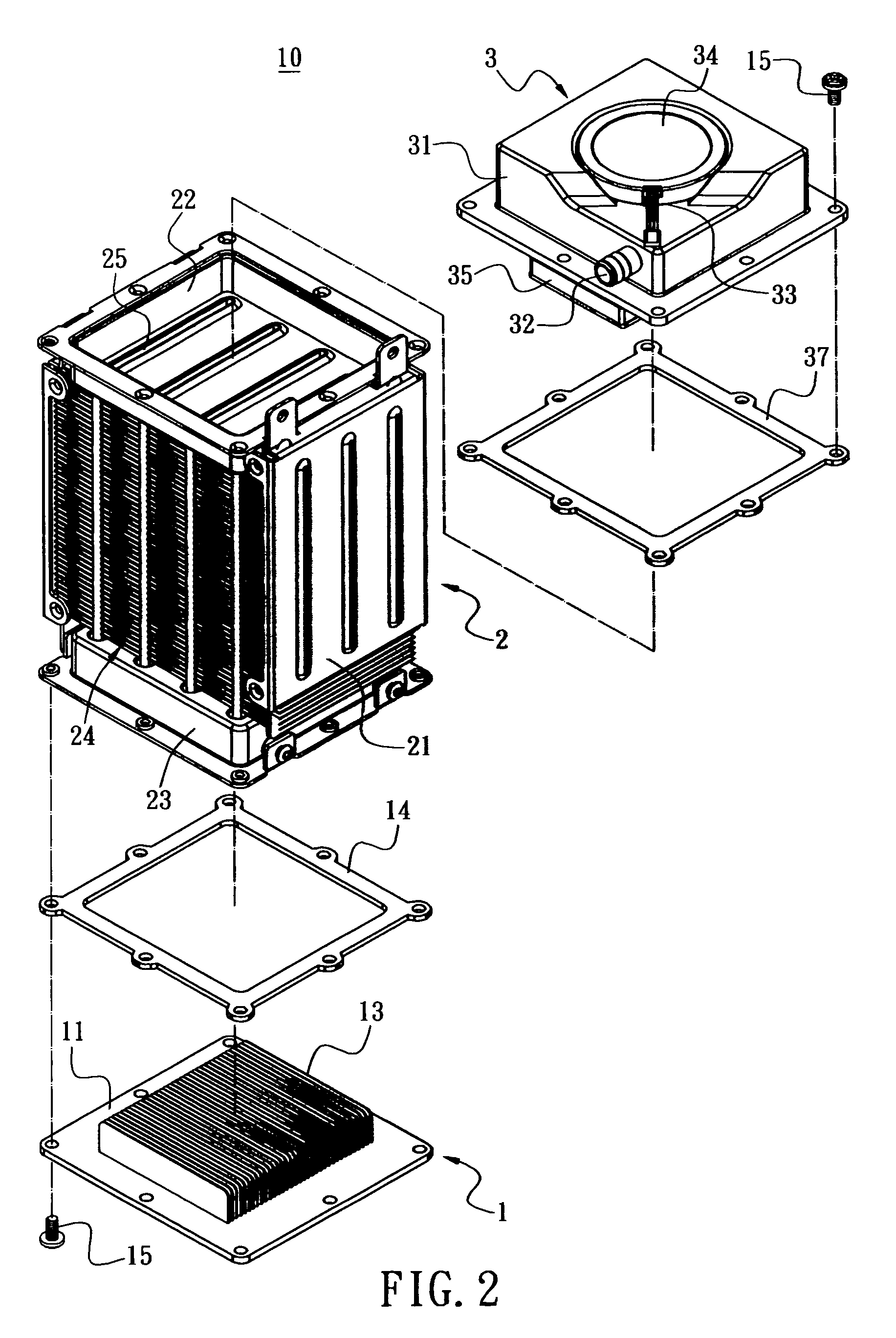

[0020] As shown in FIG. 2, the liquid-cooling heat dissipation assembly according to the present invention is used for heat dissipation of a CPU 20 shown in FIG. 7. The liquid-cooling heat dissipation assembly according to the present invention comprises, from bottom to top order, a cooling plate module 1, a liquid cooling array module 2, a liquid driving module 3 and runners define among those modules.

[0021] The liquid cooling array module 2 comprises a box 21 with an upper cover 22 and a lower cover 23 on top and bottom sides, respectively. A plurality of heat-dissipating fins 24 are provided at center of the box 21 and runners 25 are defined between the heat-dissipating fins 24. Both ends of the runner 25 are communicated with the upper cover 22 and the lower cover 23. In the shown embodiment, the cool liquid in the upper cover 22 is conveyed to the lower cover 23 through the two runners 25 at center portion; the cool liquid in the lower cover 23 is conveyed to the upper cover 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com