Multi-function downhole tool

a multi-functional, downhole technology, applied in the direction of drilling rods, drilling pipes, borehole/well accessories, etc., can solve the problems of long and costly operation, differential sticking of pipes to the wellbore wall, and high cost of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention overcomes many of the prior art problems associated with downhole apparatus. The advantages, and other features of the invention disclosed herein, will become more readily apparent to those having ordinary skill in the art from the following detailed description of certain preferred embodiments taken in conjunction with the drawings which set forth representative embodiments of the present.

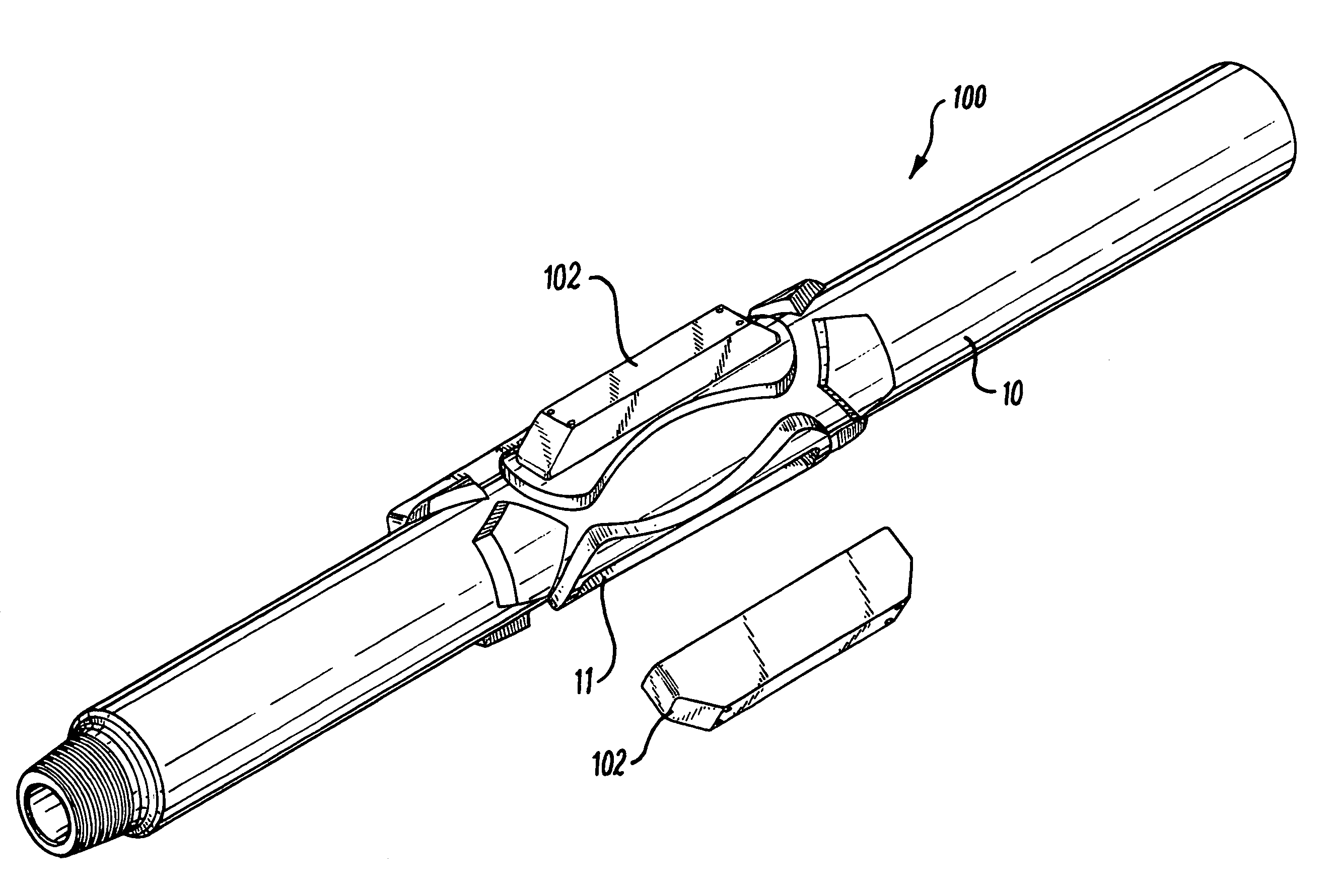

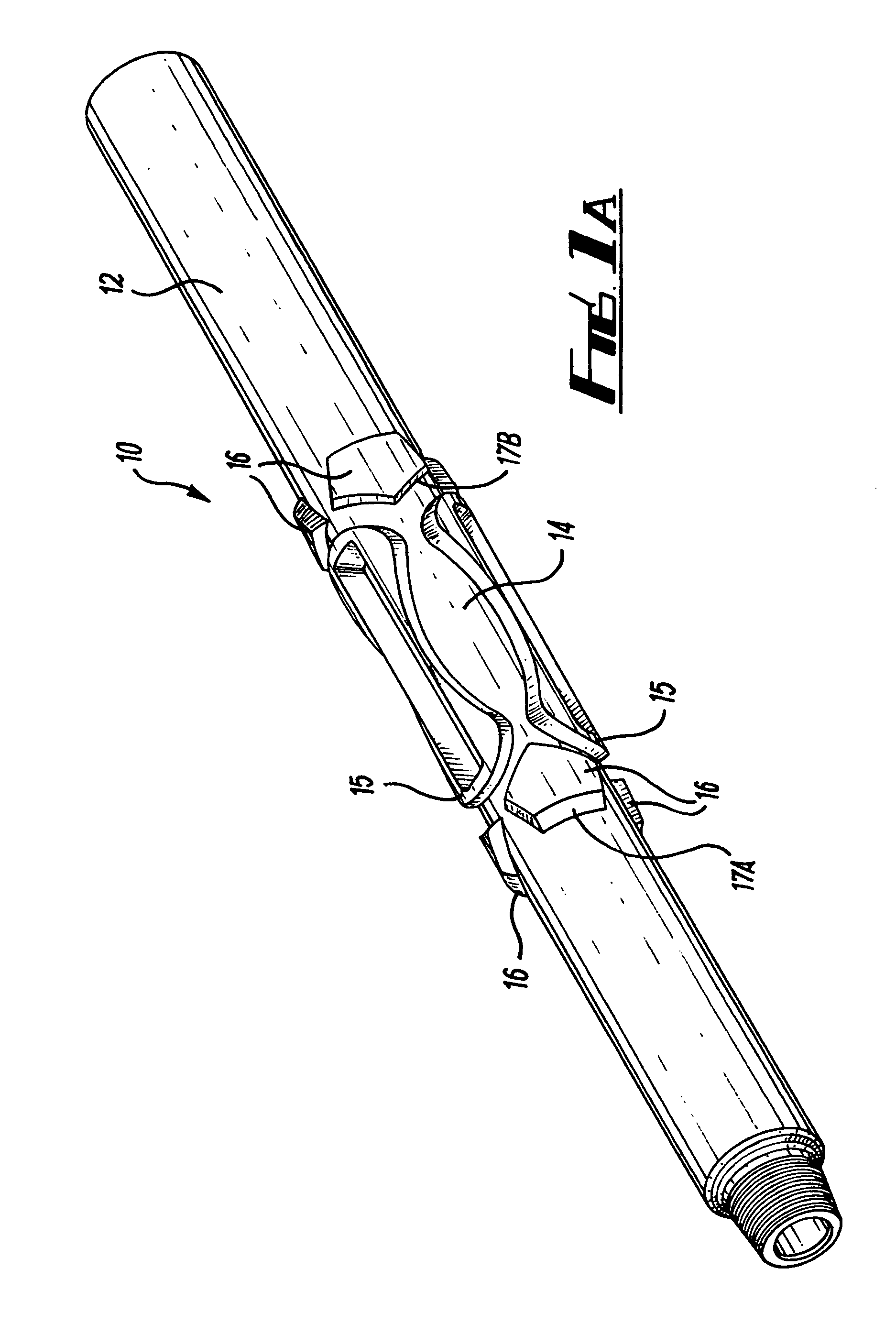

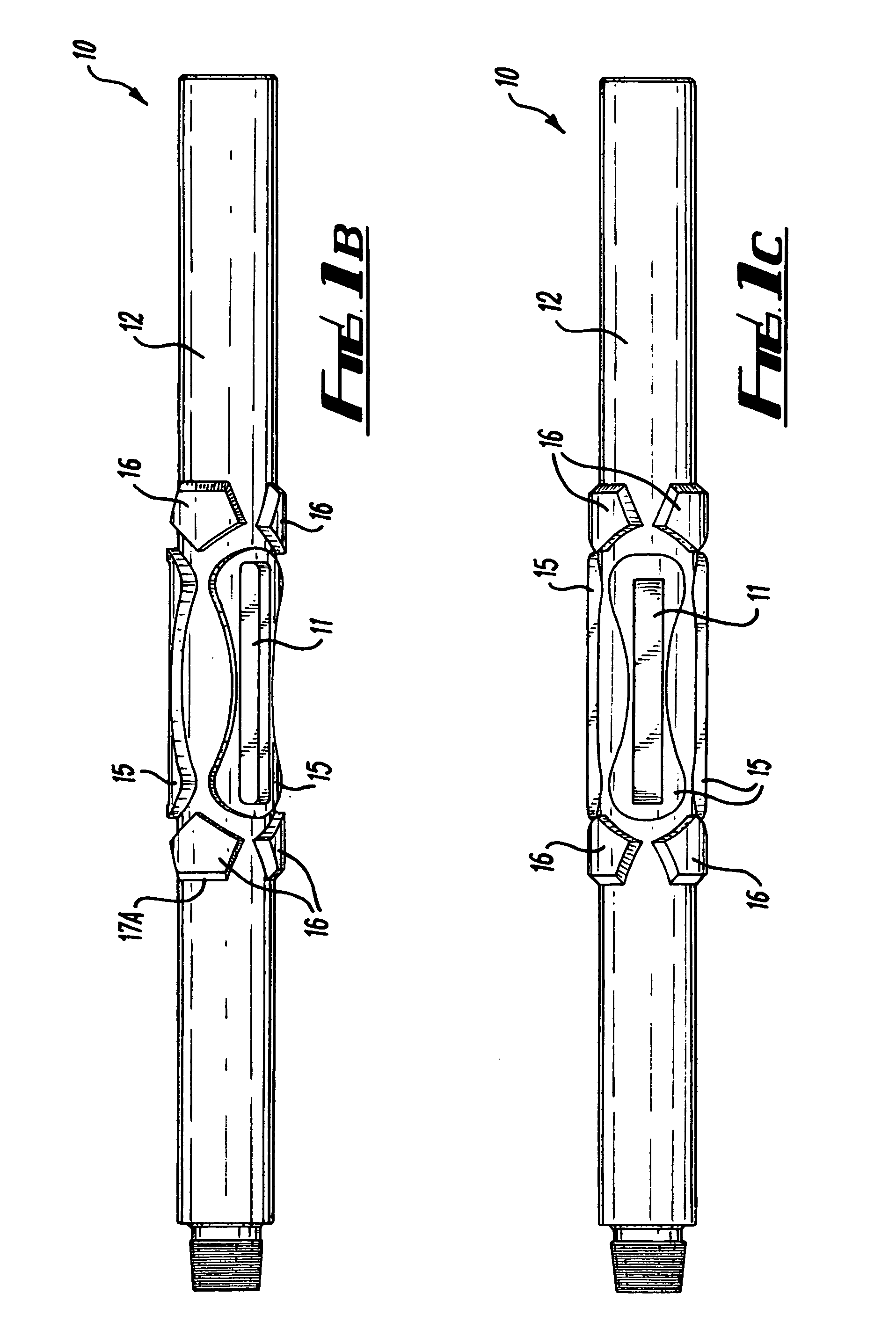

[0069] Reference is made firstly to FIGS. 1A, 1B and 1C, in which downhole apparatus in accordance with a first embodiment of the invention is shown, generally depicted at 10. As will be described in more detail below, the downhole apparatus 10 may take the form of one of a number of different types of downhole tools or equipment. However, in general terms, the downhole apparatus 10 comprises a tubular main body 12; at least one flow channel 14 extending part-way along a length of the body 12 and a plurality of raised portions or ribs 15 formed on the body 12. The rib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com