Bag type squeeze bottle

a squeeze bottle and bag-type technology, applied in the field of bag-type squeeze bottles, can solve the problems of reducing the service life of the bottle, so as to improve the service life and eliminate waste. , the effect of enhancing the performance of the bottl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

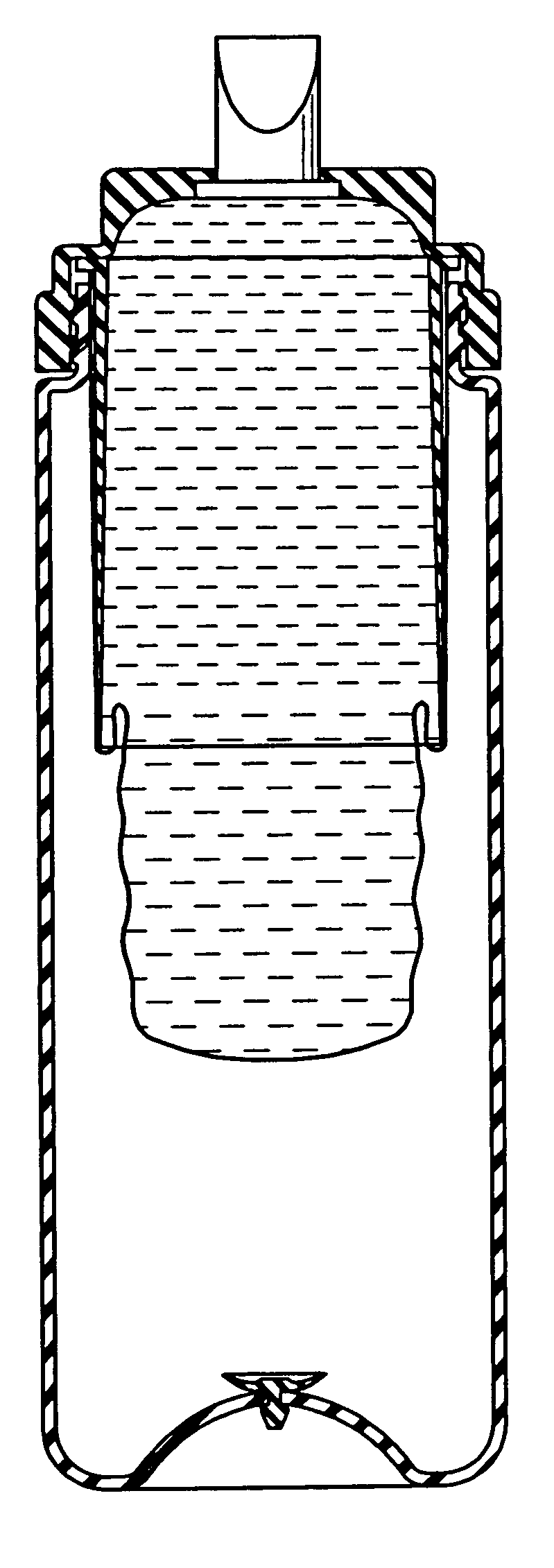

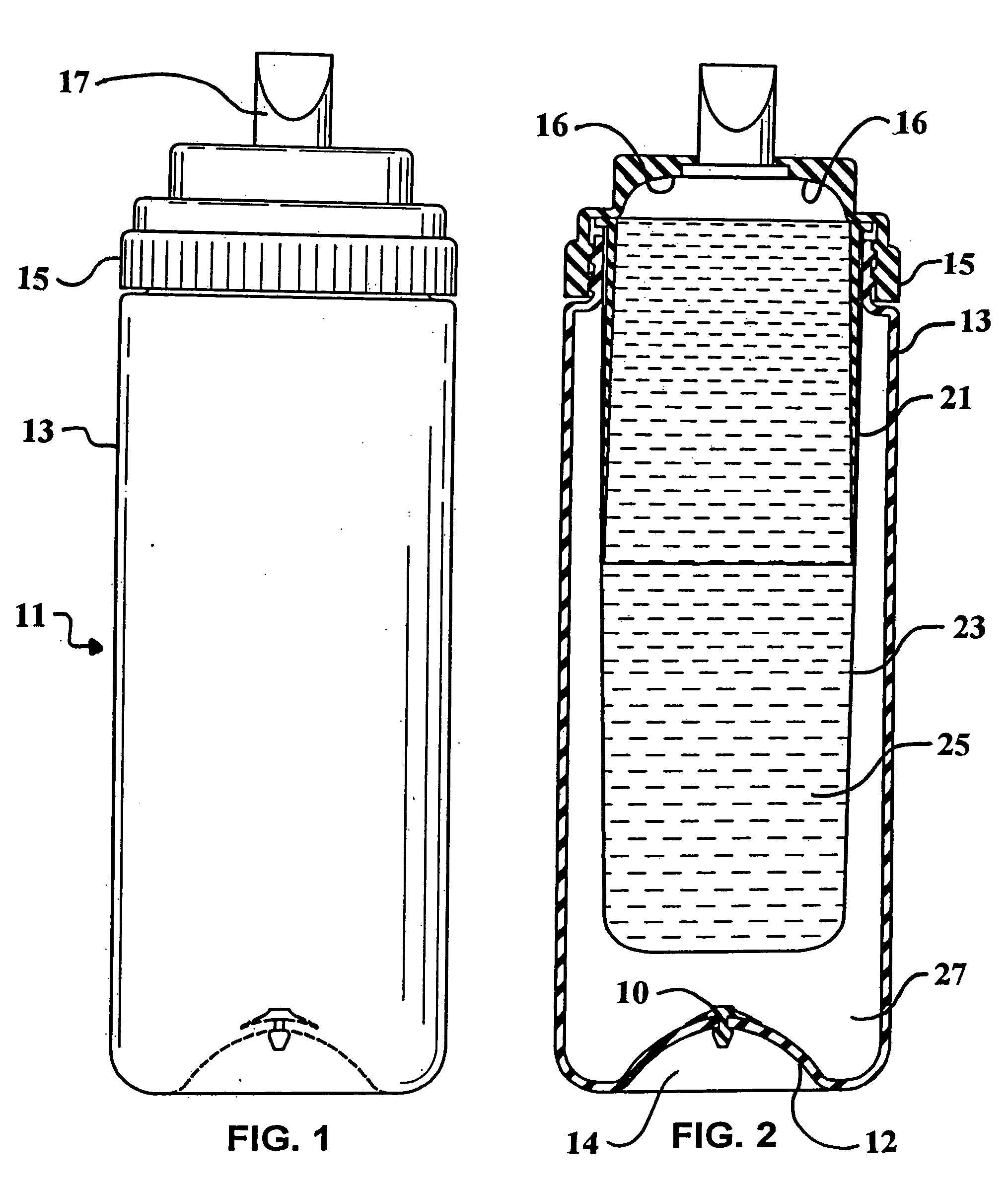

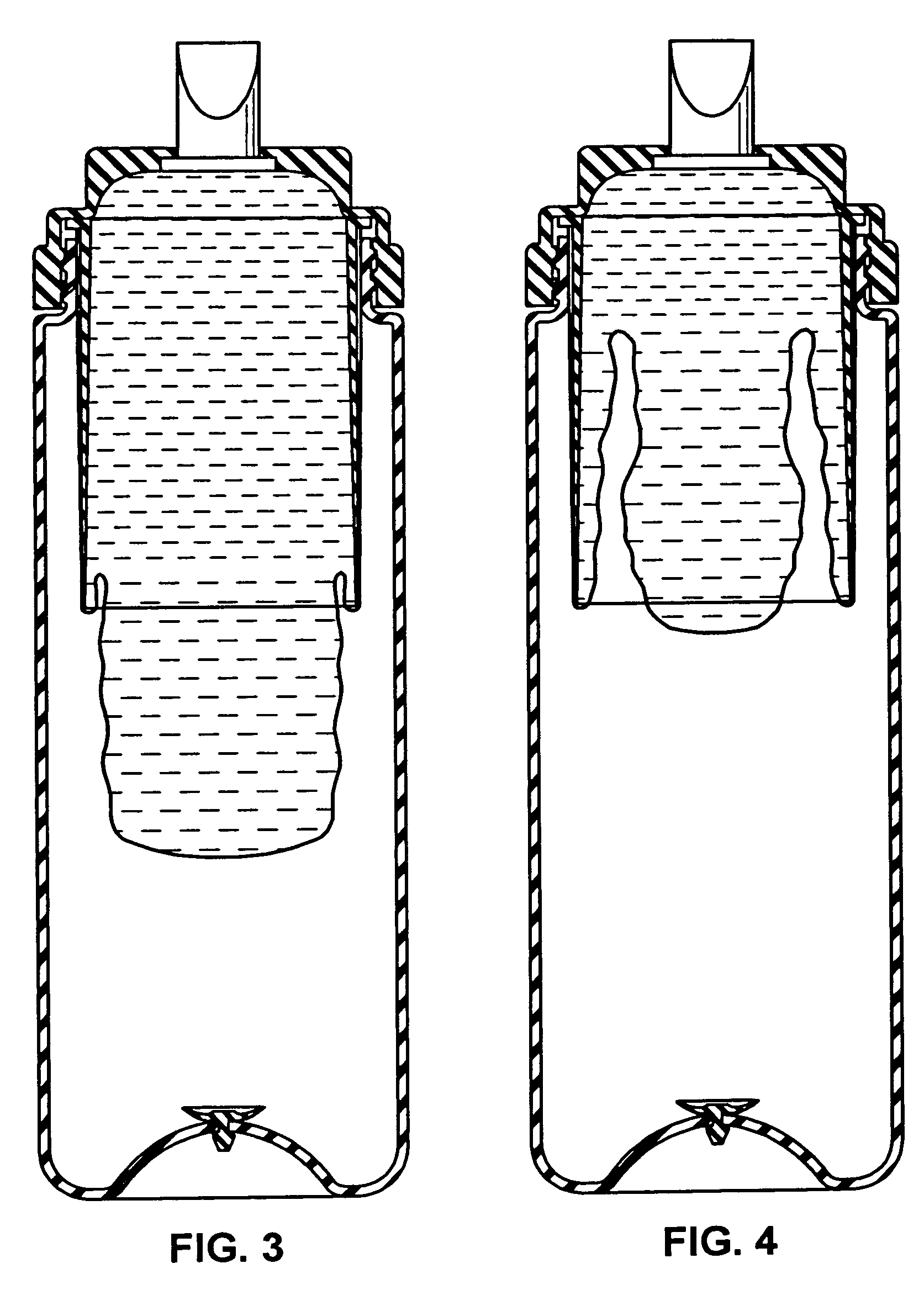

[0016] Referring now to FIG. 1, the squeeze bottle 11 of the invention generally includes a flexible outer wall which is highly resilient and dimensioned to fit comfortably within the consumer's hand for squeezing. At the top of the bottle is a removable threaded cap which carries a duckbill type dispensing nozzle 17. This duckbill nozzle known in the art includes opposing leaflets which are resiliently biased toward each other. The duckbill valve of the present invention is selected to include leaflets which are of sufficient surface area and closing force so that the valve provides both a liquid and airtight seal between the interior of the bottle and the surrounding environment. The bottom wall 12 of the bottle 11 includes a concavity 14 with an umbrella type air valve 10. This valve provides the one-way admission of air into the bottle caused by negative air pressure within which occurs when the squeezing pressure on the outside of the bottle is released and the expanding sidewa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com