Autonomous electric cleaner and electric cleaner

a technology of electric cleaners and electric cleaners, applied in vacuum cleaners, floor sweeping machines, carpet cleaners, etc., can solve the problems of affecting the travel and affecting the cleaning efficiency of the cleaning machine. , to achieve the effect of eliminating the influence of the traveling performance of the autonomous electric cleaner, suppressing the variation in the absorption rate of garbage and dust depending on the position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

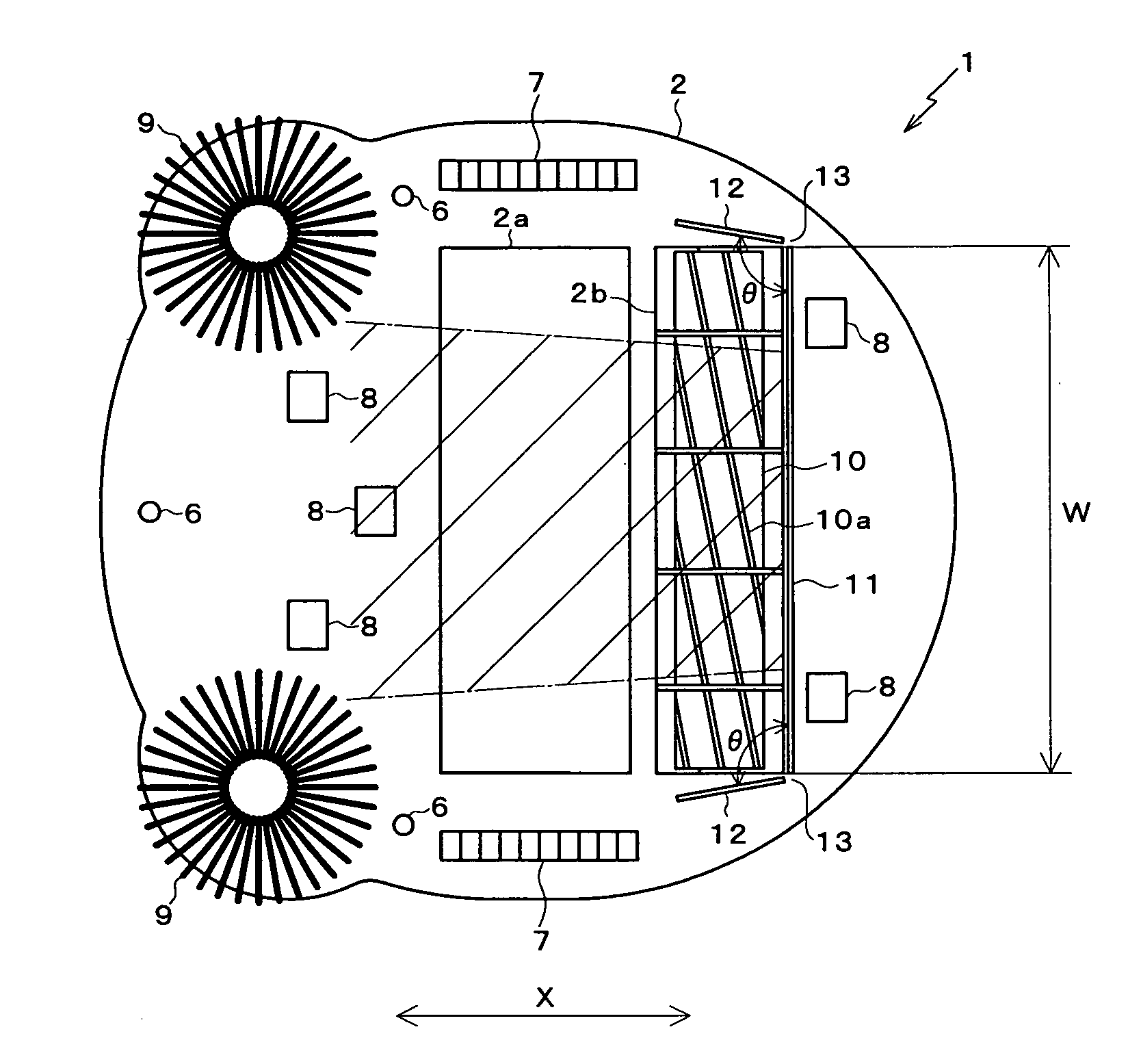

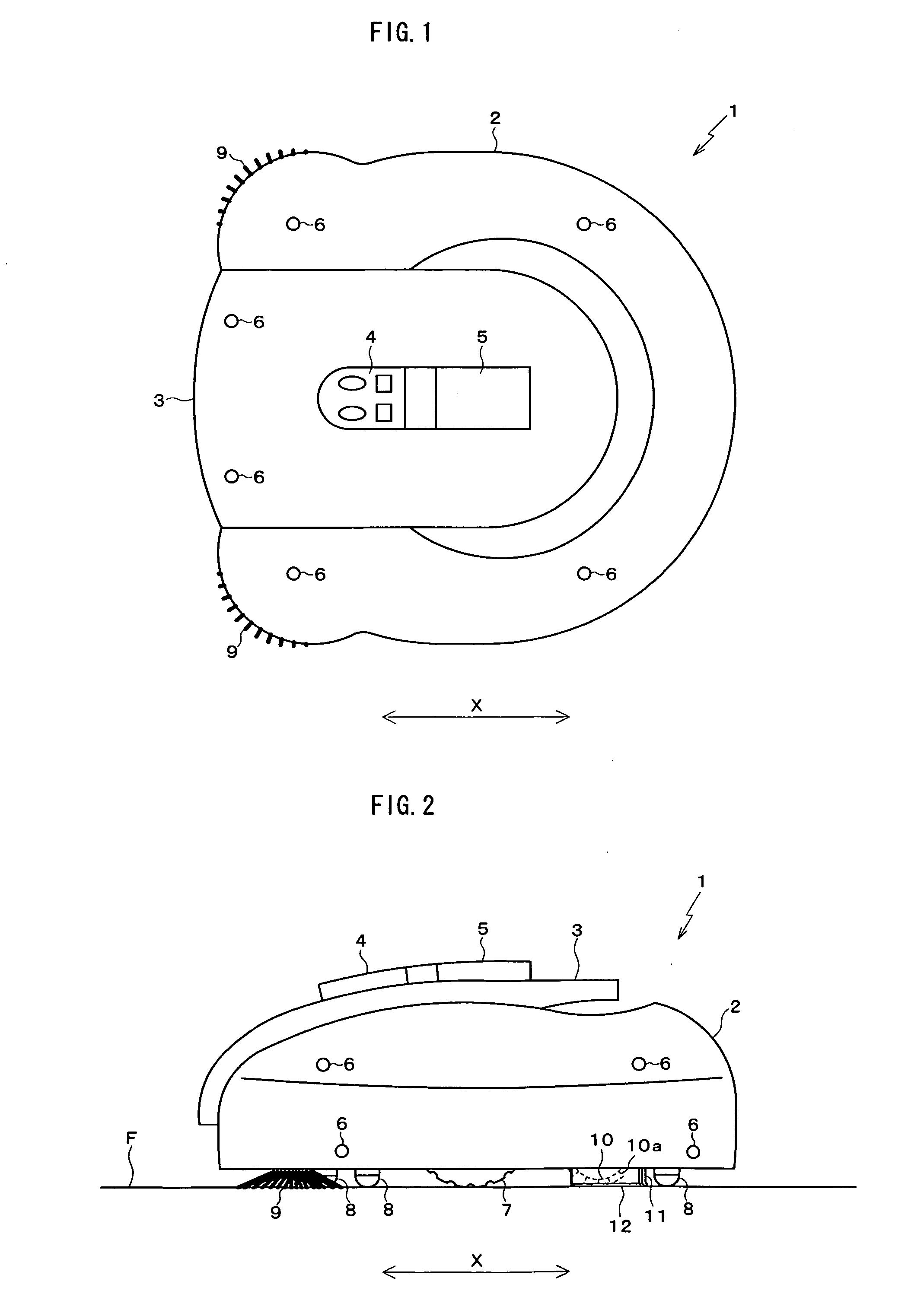

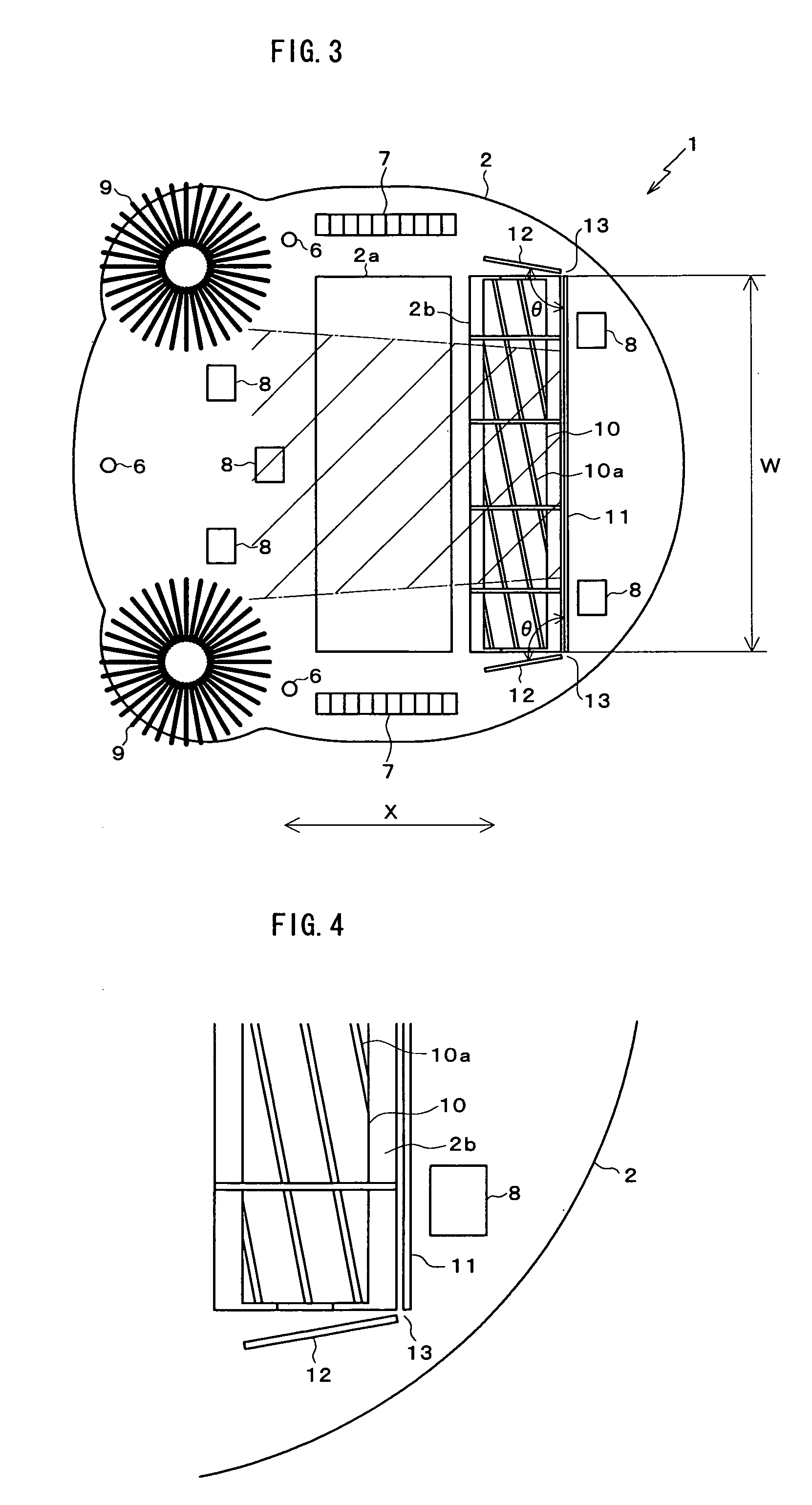

[0025]FIG. 1 is a plan view of an autonomous electric cleaner 1 according to an embodiment of the present invention. FIG. 2 is a side view of the autonomous electric cleaner 1. FIG. 3 is a bottom view of the autonomous electric cleaner 1. FIG. 4 is an enlarged view of the main part in FIG. 3. The autonomous electric cleaner (hereinafter referred to as simply “electric cleaner”) 1 autonomously travels while absorbing garbage and dust on the floor F which is a cleaning surface and cleaning the surface F.

[0026] An openable / closable cover 3 is attached to the upper part of the main body 2 of the electric cleaner 1 as shown in FIG. 1 and FIG. 2. An operating part 4 including various keys for instructing start or stop and the like of cleaning to the electric cleaner 1, and a camera 5 for photographing the surrounding are arranged at the upper part of the cover 3. The camera 5 is incorporated in the cover 3 in FIG. 1 and FIG. 2 but projects upward during photographing. A plurality of sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com