Corneal onlays and methods of producing same

a corneal onlay and corneal technology, applied in the field of corneal onlays, can solve the problems of insufficient coverage of the corneal onlay with the epithelium, many materials from which existing corneal onlays are manufactured, and ineffective promotion of epithelial cell growth and migration over the onlay, so as to improve or correct the vision of patients. , the effect of improving the patient's vision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

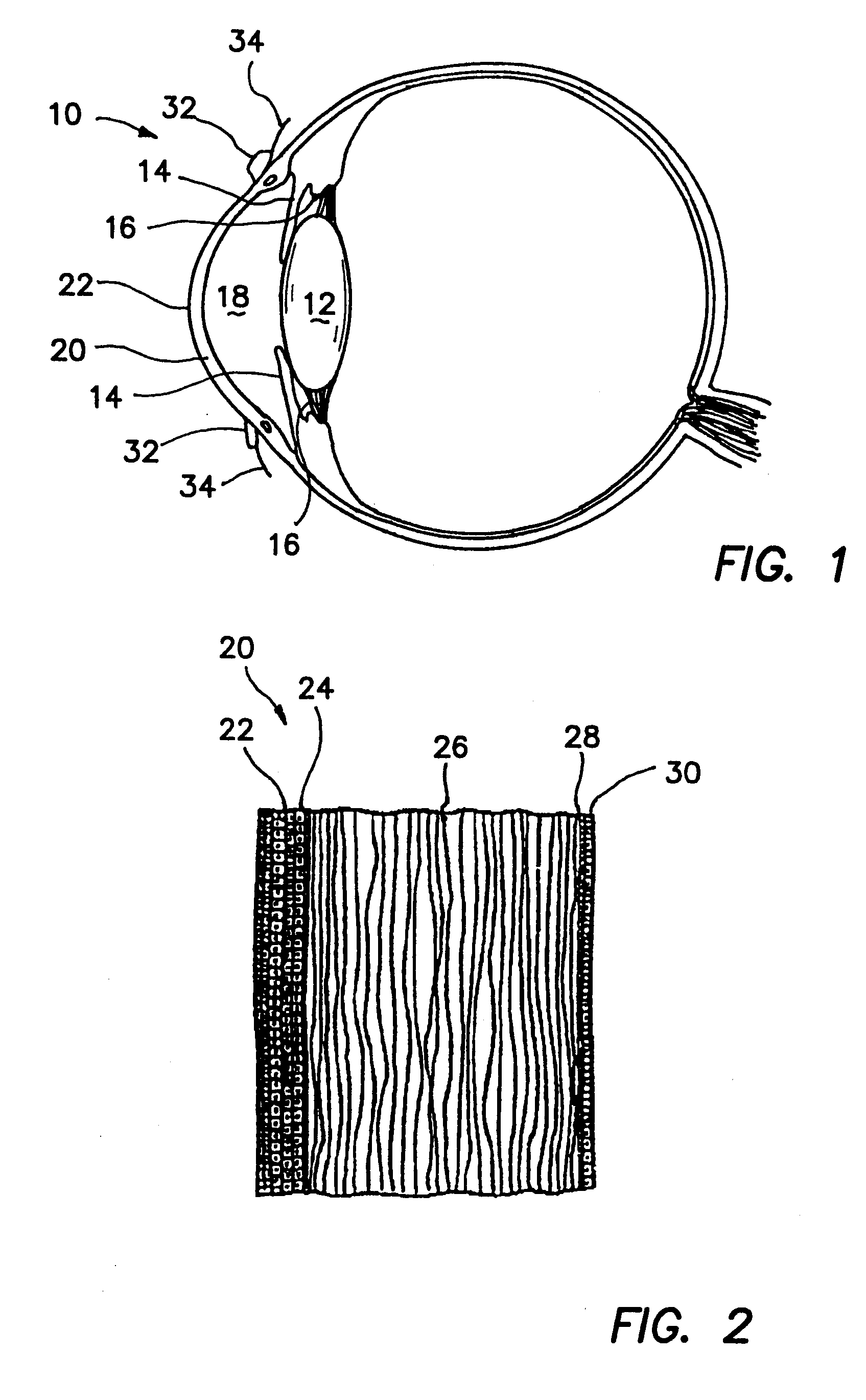

[0060] As illustrated in FIG. 1, a typical human eye 10 has a lens 12 and an iris 14. Posterior chamber 16 is located posterior to iris 14 and anterior chamber 18 is located anterior to iris 14. Eye 10 has a cornea 20 that consists of five layers, as discussed herein. One of the layers, corneal epithelium 22, lines the anterior exterior surface of cornea 20. Corneal epithelium 22 is a stratified squamous epithelium that extends laterally to the limbus 32. At limbus 32, corneal epithelium 22 becomes thicker and less regular to define the conjunctiva 34.

[0061]FIG. 2 illustrates a magnified view of the five layers of cornea 20. Typically, cornea 20 comprises corneal epithelium 22, Bowman's membrane 24, stroma 26, Descemet's membrane 28, and endothelium 30. Corneal epithelium 22 usually is about 5-6 cell layers thick (approximately 50 micrometers thick), and generally regenerates when the cornea is injured. Corneal epithelium 22 provides a relatively smooth refractive surface and helps...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com