Oil-cooler-equipped radiator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

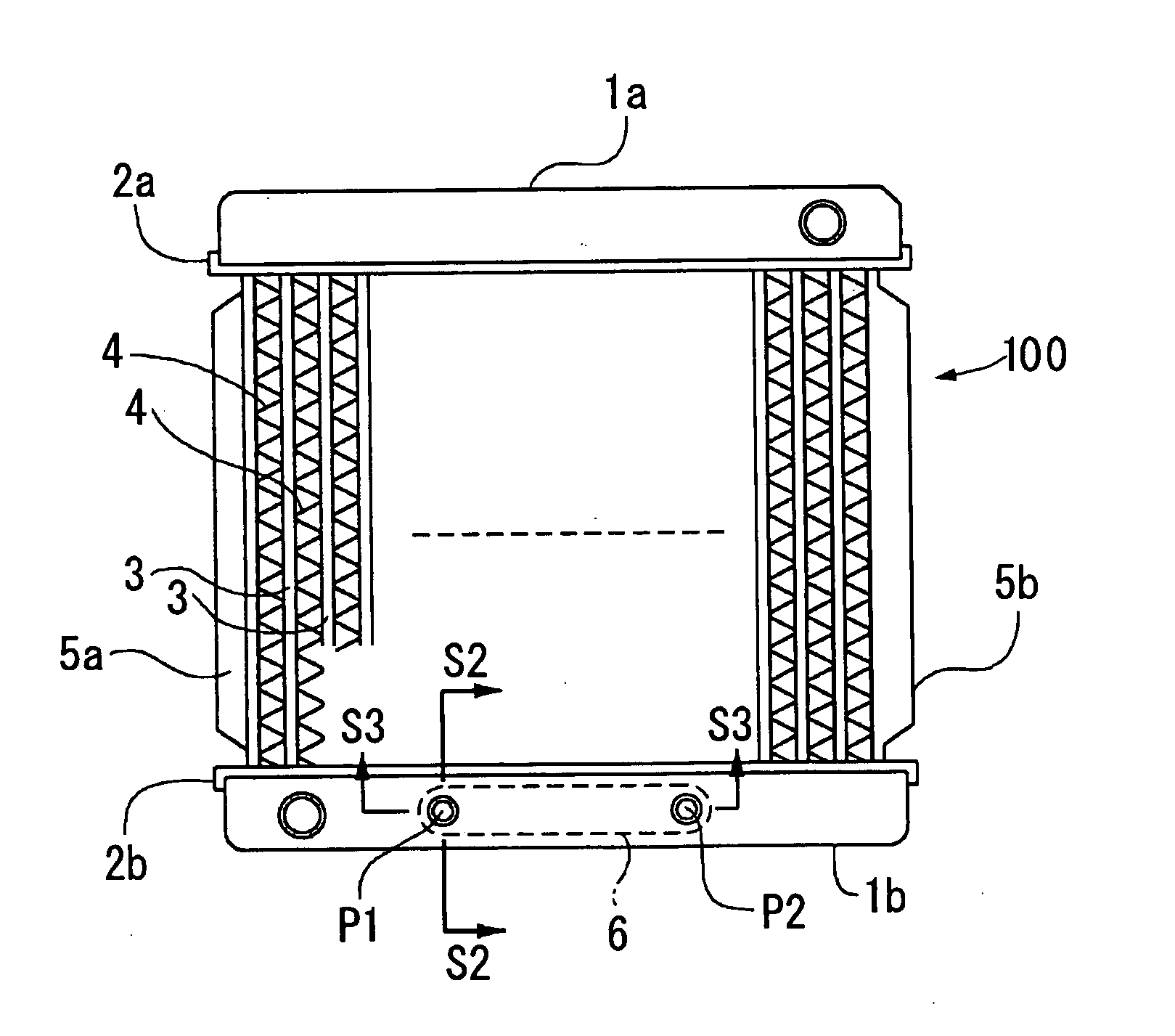

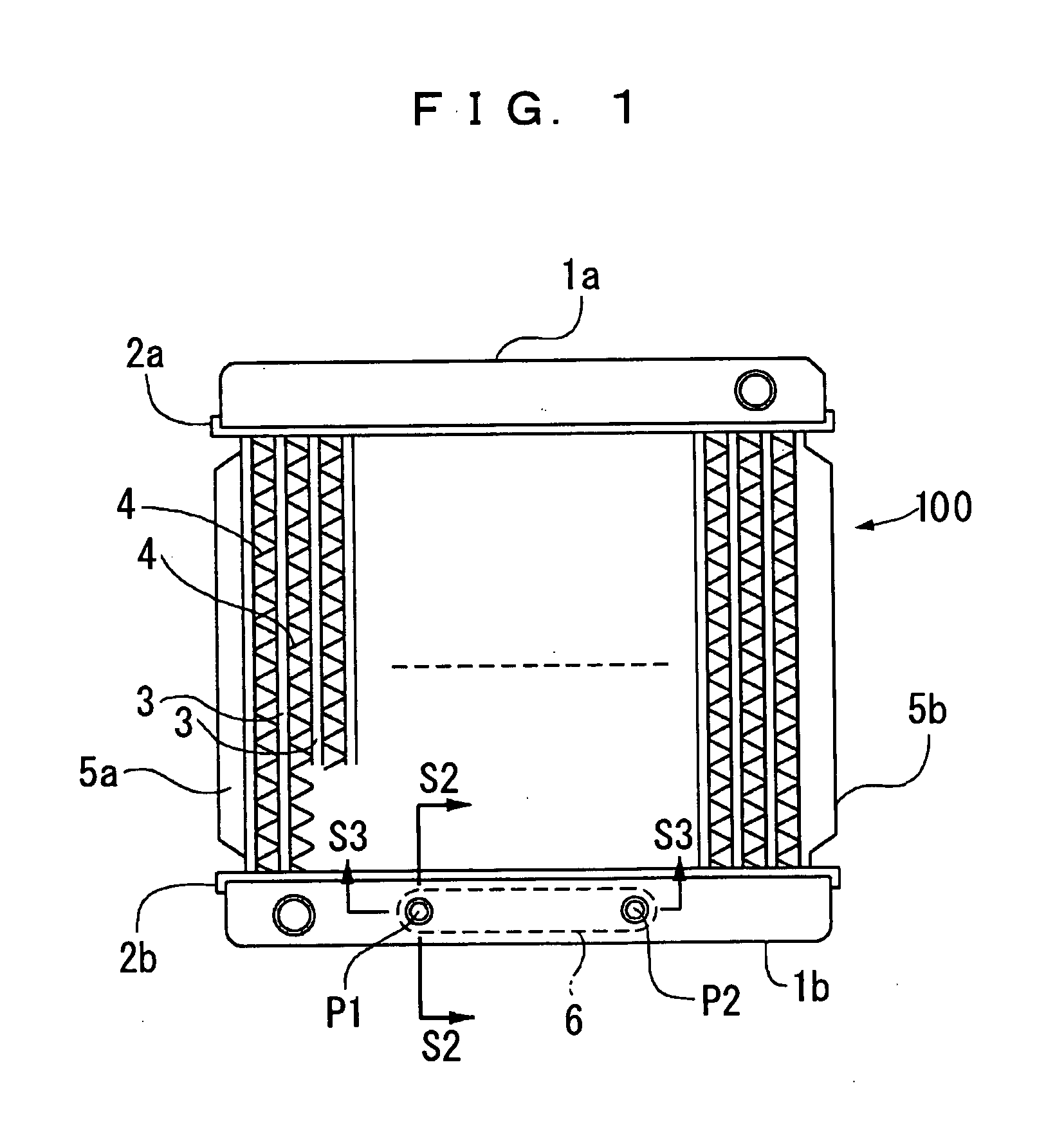

[0025] Hereinafter, an embodiment of an oil-cooler-equipped radiator according to the present invention will be described with accompanying drawings.

[0026] As shown in FIG. 1, the oil-cooler-equipped radiator according to the embodiment includes a pair of seat plates 2a and 2b provided at an upper side of a radiator 100 and at a lower side of the radiator 100 with upper and lower tanks 1a and 1b, respectively; tubes 3 and corrugated fins 4 alternately disposed between the seat plates 2a and 2b; and reinforcements 5a and 5b for connecting both end portions of the seat plates 2a and 2b at their both sides so as to reinforce them.

[0027] An oil cooler 6, which will be described in detail later, is accommodated in the lower tank 1b, and all the components including the oil cooler 6 and the lower tank 1b are made of aluminum.

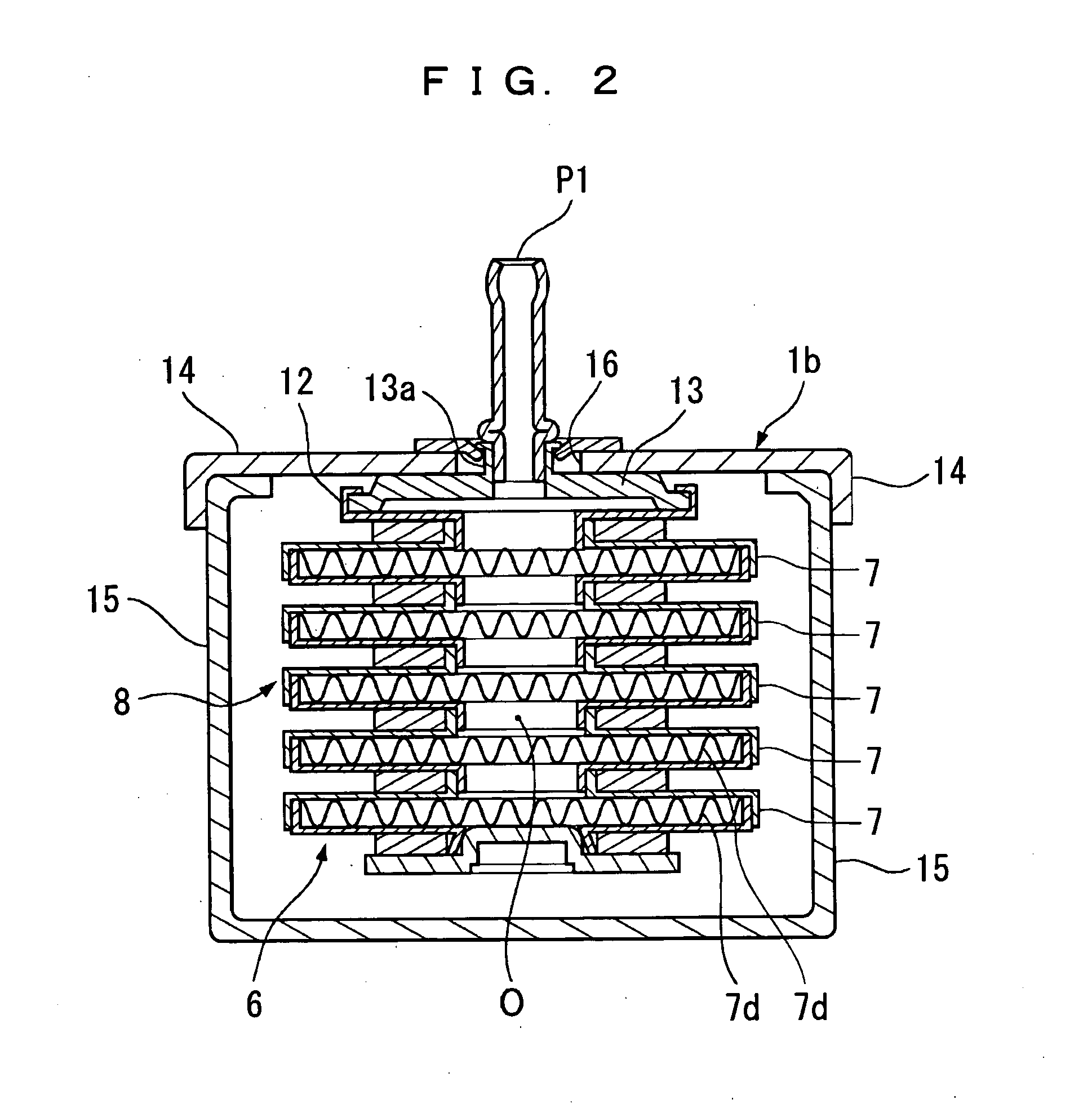

[0028] As shown in FIGS. 2 and 3, the oil cooler 6 according to the embodiment has a heat exchanger 8 including a plurality of element units 7 stacked in a state c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com