Injection compression moulding

a technology of injection compression and moulding rim, which is applied in the field of injection compression moulding, can solve the problems of difficult formation of rim closure ring, inability to form witness lines around the rim and limit the length to thickness ratio of the moulded articl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

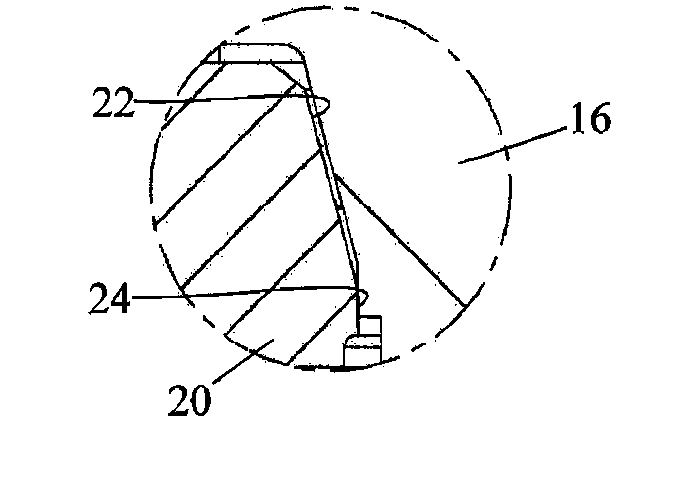

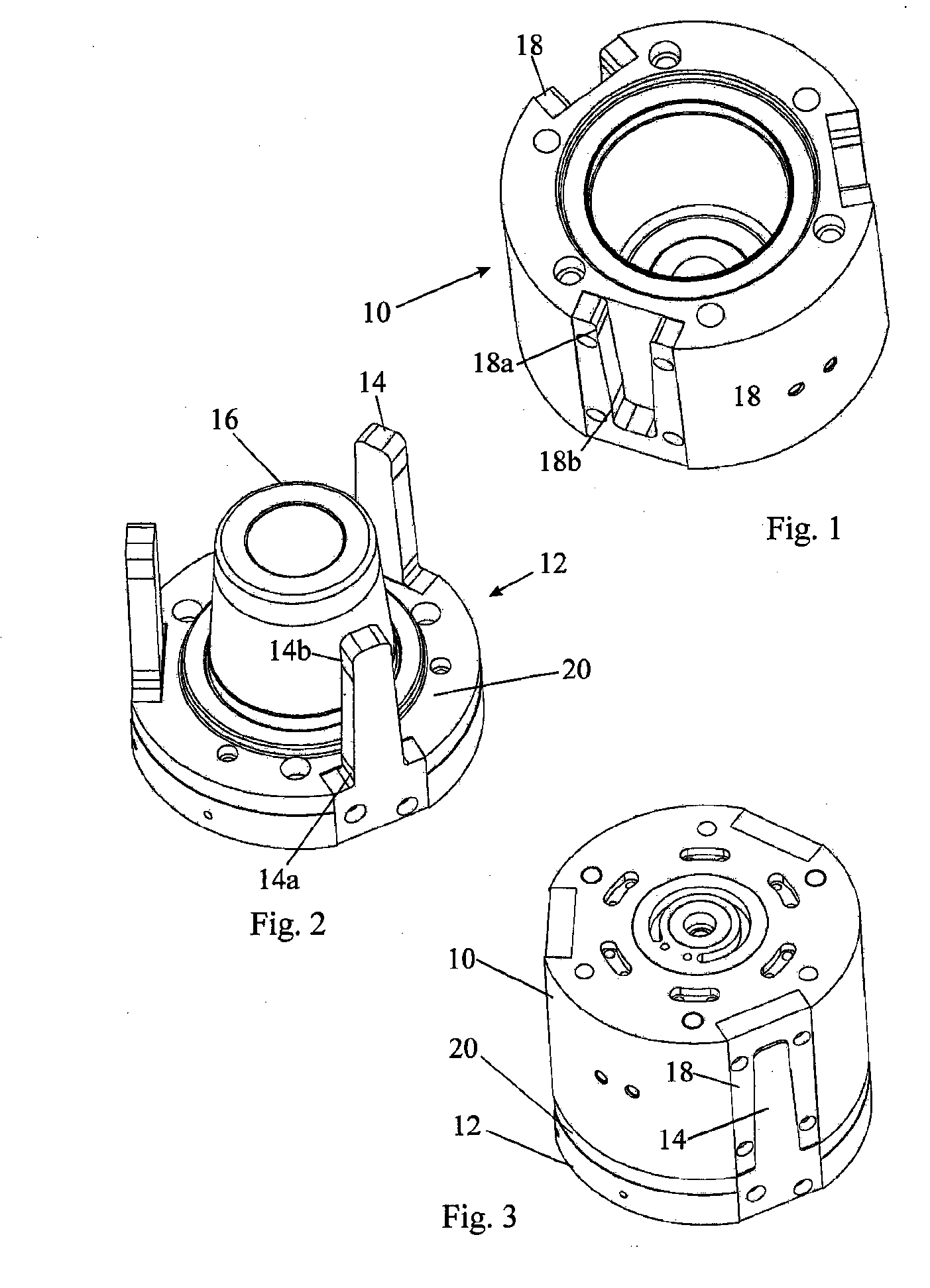

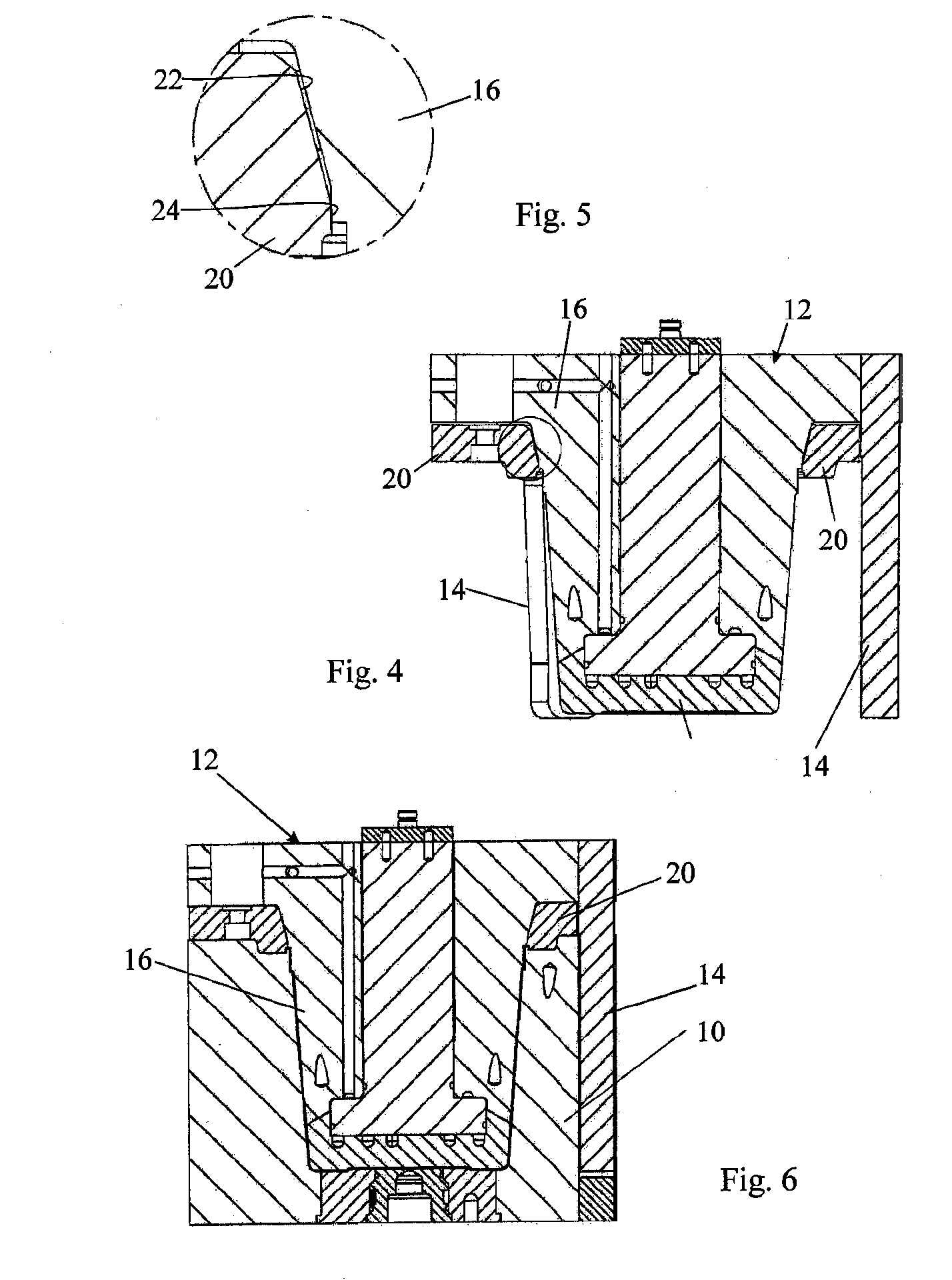

[0021] The figures show a single core / cavity set for an injection compression mould for making an article in the form of a drinking cup having a generally flat base, a frustro-conical side wall and a lip in the form of an inverted “U” surrounding the mouth of the cup. It will be appreciated that the core cavity / set may be one of many in a multi-cavity mould and that the different sets can be arranged side by side and / or stacked back to back. The ensuing description will, however, for simplicity, refer to a single cavity mould.

[0022] Referring to FIGS. 1, 2 and 3, the mould comprises a female mould part 10 and a core part 12 which fit into one another in the manner shown in FIG. 3 to leave between them a mould cavity having the desired shape of the drinking cup to be moulded.

[0023] In the illustrated embodiment of the invention, three flat guide fingers 14 are firmly secured to the core part 12 to surround a central mould core 16 in accurately predetermined positions. Each of the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com